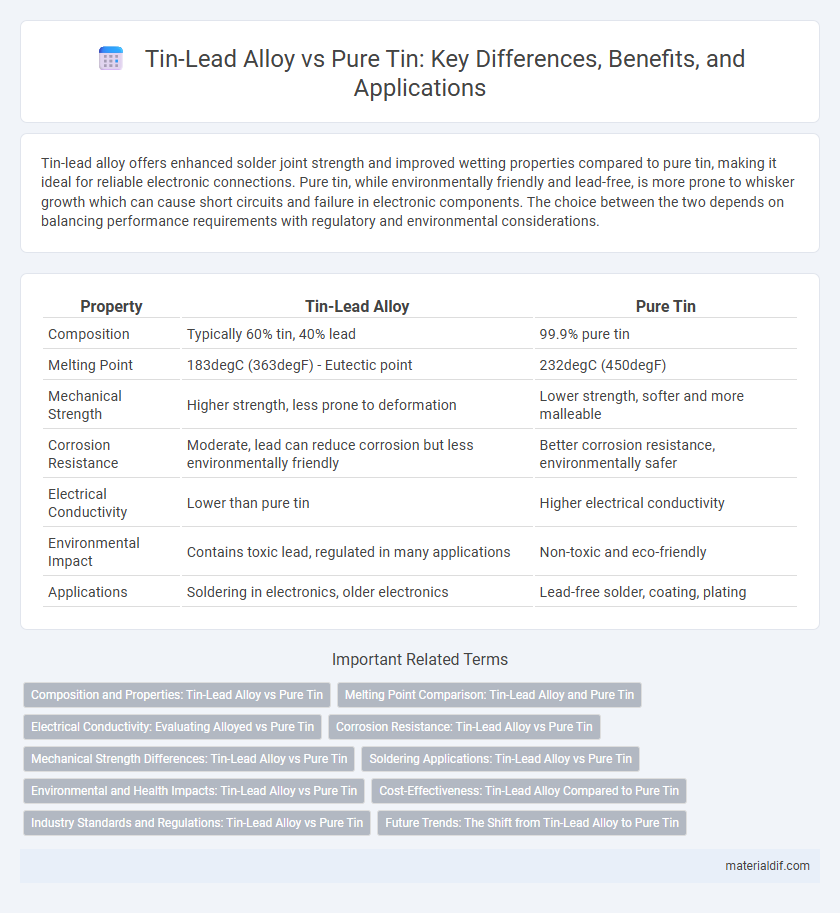

Tin-lead alloy offers enhanced solder joint strength and improved wetting properties compared to pure tin, making it ideal for reliable electronic connections. Pure tin, while environmentally friendly and lead-free, is more prone to whisker growth which can cause short circuits and failure in electronic components. The choice between the two depends on balancing performance requirements with regulatory and environmental considerations.

Table of Comparison

| Property | Tin-Lead Alloy | Pure Tin |

|---|---|---|

| Composition | Typically 60% tin, 40% lead | 99.9% pure tin |

| Melting Point | 183degC (363degF) - Eutectic point | 232degC (450degF) |

| Mechanical Strength | Higher strength, less prone to deformation | Lower strength, softer and more malleable |

| Corrosion Resistance | Moderate, lead can reduce corrosion but less environmentally friendly | Better corrosion resistance, environmentally safer |

| Electrical Conductivity | Lower than pure tin | Higher electrical conductivity |

| Environmental Impact | Contains toxic lead, regulated in many applications | Non-toxic and eco-friendly |

| Applications | Soldering in electronics, older electronics | Lead-free solder, coating, plating |

Composition and Properties: Tin-Lead Alloy vs Pure Tin

Tin-lead alloys typically consist of about 60-70% tin and 30-40% lead, offering enhanced mechanical strength, reduced melting points (around 183-190degC), and improved corrosion resistance compared to pure tin. Pure tin, with a melting point of 232degC, provides superior electrical conductivity and is more ductile but lacks the hardness and wear resistance found in tin-lead alloys. The addition of lead to tin significantly alters the alloy's physical and chemical properties, making it preferable for soldering applications where lower melting temperatures and stronger joints are essential.

Melting Point Comparison: Tin-Lead Alloy and Pure Tin

Tin-lead alloy exhibits a lower melting point compared to pure tin, typically ranging between 183degC to 190degC depending on the lead content, while pure tin melts at 231.9degC. This reduced melting point in tin-lead alloys makes them ideal for soldering applications, offering improved flow and bonding characteristics. Understanding these melting point differences is crucial in electronics and metalworking where precise thermal control is necessary.

Electrical Conductivity: Evaluating Alloyed vs Pure Tin

Pure tin exhibits higher electrical conductivity compared to tin-lead alloys due to fewer electron scattering events within its crystalline structure. Tin-lead alloys, commonly used in soldering, demonstrate reduced conductivity as lead atoms disrupt the uniform lattice, increasing electrical resistance. This difference impacts the efficiency of electrical connections, favoring pure tin for applications requiring optimal conductivity.

Corrosion Resistance: Tin-Lead Alloy vs Pure Tin

Tin-lead alloys exhibit superior corrosion resistance compared to pure tin due to the formation of a more stable, protective oxide layer that reduces metal degradation in harsh environments. Pure tin tends to suffer from tin whisker growth and faster oxidation, leading to potential reliability issues in electronic components. The addition of lead enhances the alloy's ability to resist tarnishing and corrosion, making tin-lead alloys preferable for applications requiring long-term durability.

Mechanical Strength Differences: Tin-Lead Alloy vs Pure Tin

Tin-lead alloys exhibit higher mechanical strength and improved hardness compared to pure tin due to the solid solution strengthening and the formation of intermetallic compounds. Pure tin, while softer and more ductile, lacks the enhanced resistance to deformation provided by lead additions, resulting in lower tensile strength and reduced wear resistance. These mechanical differences make tin-lead alloys preferable for applications requiring structural integrity and durability under stress.

Soldering Applications: Tin-Lead Alloy vs Pure Tin

Tin-lead alloy remains widely used in soldering applications due to its lower melting point around 183degC, providing reliable wetting and strong mechanical bonds for electronic components. Pure tin, with a higher melting point of approximately 232degC, offers lead-free alternatives essential for RoHS compliance but may exhibit increased brittleness and tin whisker growth, potentially compromising long-term circuit reliability. Selecting between tin-lead alloy and pure tin requires balancing solder joint durability, regulatory standards, and thermal processing requirements in electronic manufacturing.

Environmental and Health Impacts: Tin-Lead Alloy vs Pure Tin

Tin-lead alloys contain lead, a toxic heavy metal that poses significant environmental and health risks, including soil contamination and neurological damage upon exposure. Pure tin eliminates lead-related hazards, offering a safer alternative with lower toxicity and reduced environmental persistence. Regulatory restrictions on lead usage have driven the shift towards pure tin to minimize health impacts and promote sustainable manufacturing practices.

Cost-Effectiveness: Tin-Lead Alloy Compared to Pure Tin

Tin-lead alloy generally offers superior cost-effectiveness compared to pure tin due to its lower melting point, which reduces energy consumption during manufacturing. The alloy's enhanced mechanical properties allow for thinner coatings, minimizing material usage and further cutting costs. Despite concerns about lead content, tin-lead alloys remain economically favorable in applications where cost and performance balance is critical.

Industry Standards and Regulations: Tin-Lead Alloy vs Pure Tin

Tin-lead alloys, historically prevalent in electronics soldering, face stringent restrictions under RoHS (Restriction of Hazardous Substances) directives due to lead content, prompting industries to shift towards pure tin or lead-free alternatives to comply with environmental and safety standards. Pure tin offers compliance benefits in manufacturing processes, meeting global regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) that limit hazardous substances in consumer products. Adoption of pure tin aligns with industry standards for sustainable production, minimizing health risks and environmental impact without sacrificing soldering effectiveness.

Future Trends: The Shift from Tin-Lead Alloy to Pure Tin

The electronics industry is rapidly transitioning from tin-lead alloys to pure tin due to stricter environmental regulations like RoHS and REACH, which limit the use of hazardous substances. Advances in pure tin plating technologies improve solder joint reliability and reduce issues such as whisker growth, making pure tin more viable for high-performance applications. Emerging trends emphasize lead-free solder materials, with pure tin gaining preference for eco-friendly manufacturing and sustainable electronics production.

Tin-lead alloy vs Pure tin Infographic

materialdif.com

materialdif.com