Hot-dip tin coating offers a thicker, more uniform layer of tin compared to electrolytic tin coating, providing superior corrosion resistance and durability for metal parts. Electrolytic tin coating allows for precise control over coating thickness and is ideal for applications requiring fine tolerance and smoother finishes. Both methods enhance solderability, but hot-dip tin is commonly used for heavy-duty protection while electrolytic tin is preferred for delicate electronic components.

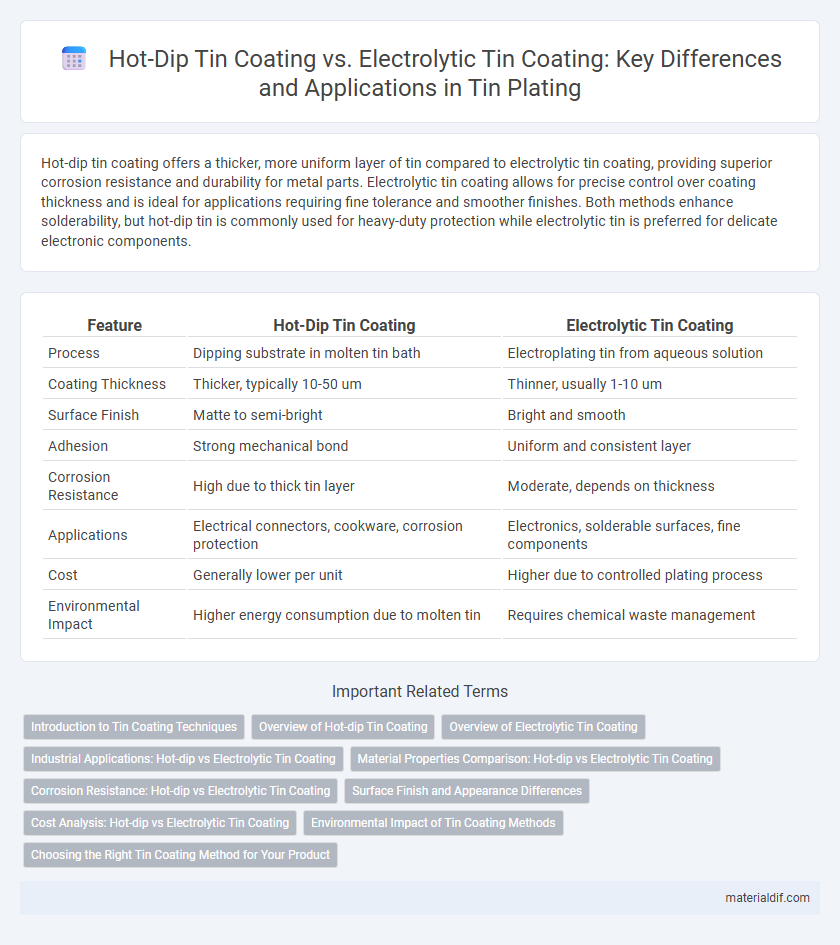

Table of Comparison

| Feature | Hot-Dip Tin Coating | Electrolytic Tin Coating |

|---|---|---|

| Process | Dipping substrate in molten tin bath | Electroplating tin from aqueous solution |

| Coating Thickness | Thicker, typically 10-50 um | Thinner, usually 1-10 um |

| Surface Finish | Matte to semi-bright | Bright and smooth |

| Adhesion | Strong mechanical bond | Uniform and consistent layer |

| Corrosion Resistance | High due to thick tin layer | Moderate, depends on thickness |

| Applications | Electrical connectors, cookware, corrosion protection | Electronics, solderable surfaces, fine components |

| Cost | Generally lower per unit | Higher due to controlled plating process |

| Environmental Impact | Higher energy consumption due to molten tin | Requires chemical waste management |

Introduction to Tin Coating Techniques

Hot-dip tin coating involves immersing metal substrates in molten tin, creating a thick, uniform layer that offers excellent corrosion resistance and solderability. Electrolytic tin coating uses an electroplating process to deposit a controlled, thin tin layer with superior surface finish and precise thickness control. Both techniques enhance tin's protective properties on metal parts, playing crucial roles in electronics and packaging industries.

Overview of Hot-dip Tin Coating

Hot-dip tin coating involves immersing metal parts into molten tin, creating a thick, uniform layer that provides excellent corrosion resistance and solderability. This process produces a more robust and durable tin layer compared to electrolytic tin coating, which applies tin through electroplating, resulting in a thinner and less uniform finish. Hot-dip tin coatings are widely used in applications requiring long-lasting protection against oxidation and mechanical wear.

Overview of Electrolytic Tin Coating

Electrolytic tin coating involves the deposition of pure tin onto a metal substrate through an electroplating process, offering precise control over coating thickness and uniformity. This method enhances corrosion resistance, solderability, and electrical conductivity, making it ideal for electronic components and connectors. Its ability to produce smooth, adherent coatings with excellent coverage on complex geometries distinguishes it from hot-dip tin coating.

Industrial Applications: Hot-dip vs Electrolytic Tin Coating

Hot-dip tin coating provides a thicker, more durable layer ideal for automotive and heavy machinery components exposed to harsh environments. Electrolytic tin coating delivers a thinner, more uniform finish preferred in electronics and precision instruments where corrosion resistance and electrical conductivity are critical. Industrial applications select hot-dip for robust, structural protection, while electrolytic tin suits delicate, high-performance parts requiring precise coating control.

Material Properties Comparison: Hot-dip vs Electrolytic Tin Coating

Hot-dip tin coating exhibits superior corrosion resistance due to its thicker and more uniform layer compared to electrolytic tin coating, which typically results in a thinner deposit. The hot-dip process produces a metallurgically bonded interface with the substrate, enhancing adhesion and durability under mechanical stress. Electrolytic tin coating offers better control over coating thickness and surface finish, making it suitable for applications requiring precise dimensional tolerances.

Corrosion Resistance: Hot-dip vs Electrolytic Tin Coating

Hot-dip tin coating provides superior corrosion resistance due to its thicker, more uniform layer that offers enhanced protection against moisture and chemical exposure compared to electrolytic tin coating. Electrolytic tin coating, while thinner and more precise, is more susceptible to wear and less effective in harsh environments. The increased corrosion resistance of hot-dip coating makes it ideal for applications requiring long-term durability and environmental resilience.

Surface Finish and Appearance Differences

Hot-dip tin coating produces a thicker, more uniform layer with a matte gray finish due to the immersion of the substrate in molten tin, resulting in a robust, corrosion-resistant surface. Electrolytic tin coating yields a thinner, brighter, and smoother surface with a shiny silver appearance from the controlled deposition of tin ions via electroplating, enhancing fine surface detail and solderability. The choice between hot-dip and electrolytic coatings depends on desired surface aesthetics, thickness requirements, and application-specific performance criteria.

Cost Analysis: Hot-dip vs Electrolytic Tin Coating

Hot-dip tin coating typically incurs higher initial costs due to large-scale equipment and energy consumption, but it offers superior thickness uniformity and corrosion resistance, potentially reducing long-term maintenance expenses. Electrolytic tin coating features lower upfront investment and precise thickness control, making it cost-effective for high-volume, thin-layer applications despite slightly higher operational costs related to chemical handling. Evaluating overall expenses requires balancing hot-dip's durability benefits against electrolytic's efficiency advantages in specific industrial contexts.

Environmental Impact of Tin Coating Methods

Hot-dip tin coating involves immersing substrates in molten tin, producing a thicker, more uniform layer that can reduce corrosion and extend product lifespan, which positively affects environmental sustainability by decreasing material waste and replacement frequency. Electrolytic tin coating uses an electric current to deposit tin layers, typically thinner and more controlled, reducing tin consumption and minimizing hazardous waste generation during the plating process. The environmental impact of hot-dip methods may include higher energy usage and potential emissions from molten tin handling, whereas electrolytic coating offers lower energy demand and less Scrap material, aligning better with eco-friendly manufacturing practices.

Choosing the Right Tin Coating Method for Your Product

Hot-dip tin coating offers a thick, uniform layer ideal for corrosion resistance in heavy-duty applications, while electrolytic tin coating provides a thinner, precision-controlled layer suited for delicate electronic components. Selecting the appropriate tin coating method depends on factors such as product weight tolerance, required coating thickness, and environmental exposure. Understanding these parameters ensures optimal performance, longevity, and cost-efficiency for your tin-coated product.

Hot-dip Tin Coating vs Electrolytic Tin Coating Infographic

materialdif.com

materialdif.com