Terne plate, composed of a lead-tin alloy coating on steel, offers superior corrosion resistance compared to pure tin plate, which features a thin layer of nearly pure tin. Pure tin plate provides excellent solderability and a bright, smooth surface ideal for food and chemical packaging. Choosing between terne plate and pure tin plate depends on the specific application requirements, balancing corrosion resistance and surface finish.

Table of Comparison

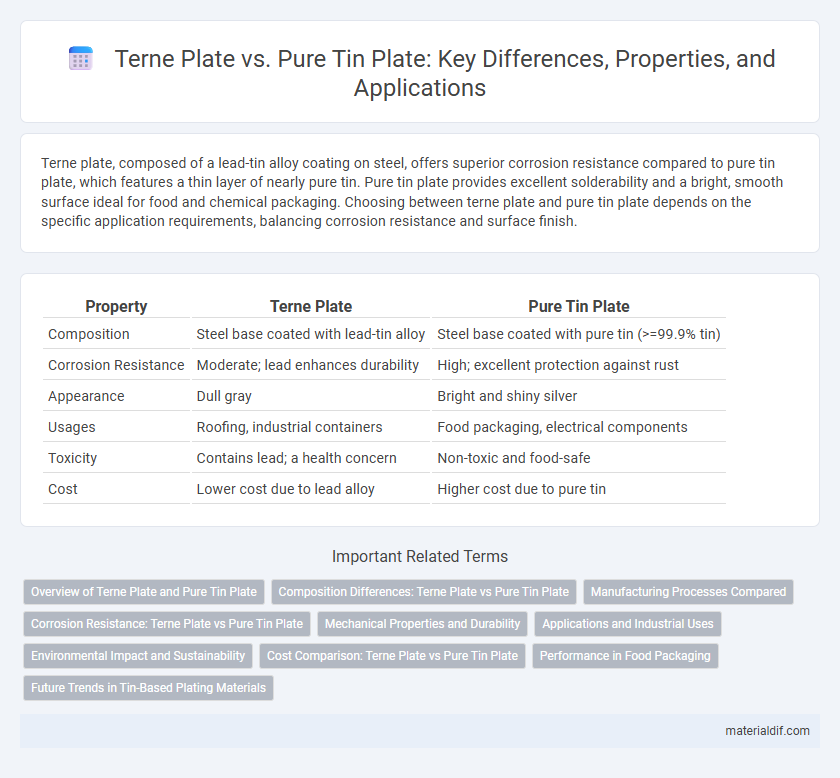

| Property | Terne Plate | Pure Tin Plate |

|---|---|---|

| Composition | Steel base coated with lead-tin alloy | Steel base coated with pure tin (>=99.9% tin) |

| Corrosion Resistance | Moderate; lead enhances durability | High; excellent protection against rust |

| Appearance | Dull gray | Bright and shiny silver |

| Usages | Roofing, industrial containers | Food packaging, electrical components |

| Toxicity | Contains lead; a health concern | Non-toxic and food-safe |

| Cost | Lower cost due to lead alloy | Higher cost due to pure tin |

Overview of Terne Plate and Pure Tin Plate

Terne plate consists of a steel sheet coated with an alloy of tin and lead, offering enhanced corrosion resistance and durability compared to pure tin plate, which is a steel sheet coated solely with tin. Terne plates are commonly used in roofing and industrial applications due to their textured surface and excellent weather resistance, while pure tin plates are favored in food packaging and electronics for their non-toxic and anti-corrosive properties. The choice between terne plate and pure tin plate depends on specific use cases, with terne plate providing cost-effective protection in outdoor environments and pure tin plate ensuring safety and cleanliness in consumer goods.

Composition Differences: Terne Plate vs Pure Tin Plate

Terne plate consists of a steel base coated with an alloy of lead and tin, typically comprising about 80-90% lead and 10-20% tin, providing enhanced corrosion resistance and a matte finish. Pure tin plate features a steel substrate coated with nearly 99.9% pure tin, offering superior solderability and a bright, reflective surface. The key composition difference lies in terne plate's use of a lead-tin alloy versus pure tin plate's almost exclusive tin coating, impacting properties such as corrosion resistance, malleability, and environmental considerations.

Manufacturing Processes Compared

Terne plate is manufactured by coating steel with an alloy of tin and lead using hot-dipping, which creates a corrosion-resistant surface with enhanced durability, whereas pure tin plate involves electroplating a uniform layer of pure tin onto steel providing superior solderability and food safety. The hot-dip process in terne plating allows for thicker, uneven coatings suitable for roofing and industrial applications, while pure tin plating's electrochemical method ensures precise, thin, and consistent coatings favored in food packaging and electronics. Manufacturing differences significantly impact the final product's corrosion resistance, mechanical properties, and application suitability.

Corrosion Resistance: Terne Plate vs Pure Tin Plate

Terne plate, an alloy-coated steel primarily composed of lead and tin, offers superior corrosion resistance compared to pure tin plate due to its robust protective layer that resists moisture and chemical exposure. Pure tin plate provides excellent corrosion resistance in non-aggressive environments, but terne plate outperforms in harsh conditions like marine or industrial atmospheres. The enhanced durability of terne plate is attributed to its alloy composition, which forms a more resilient barrier against oxidation and rust.

Mechanical Properties and Durability

Terne plate, composed of steel coated with a lead-tin alloy, exhibits enhanced mechanical strength and superior resistance to wear compared to pure tin plate, making it more suitable for applications requiring durability under stress. Pure tin plate offers better corrosion resistance but is softer and less resilient under mechanical loads, limiting its use in high-stress environments. The combination of lead with tin in terne plates improves hardness and prolongs service life, whereas pure tin plates excel in environments prioritizing non-toxicity and flexibility.

Applications and Industrial Uses

Terne plate, a steel sheet coated with a lead-tin alloy, is primarily used in roofing, gutter systems, and automotive parts due to its corrosion resistance and ease of soldering. Pure tin plate, consisting of a thin layer of pure tin on a steel substrate, finds extensive applications in food packaging, electronics, and electrical components for its excellent anti-corrosive properties and solderability. Industrial uses of terne plate emphasize durability in outdoor environments, while pure tin plate is favored for hygienic and conductive applications.

Environmental Impact and Sustainability

Terne plate, coated with a lead-tin alloy, poses significant environmental concerns due to lead's toxicity and challenges in recycling, leading to soil and water contamination. Pure tin plate offers a more sustainable alternative, reducing hazardous waste and enhancing recyclability because tin is non-toxic and environmentally benign. The shift to pure tin plate aligns with global sustainability goals by minimizing ecological risks and promoting safer waste management practices.

Cost Comparison: Terne Plate vs Pure Tin Plate

Terne plate, made by coating steel with a tin-lead alloy, generally costs less than pure tin plate due to the lower price of lead compared to tin. Pure tin plate offers superior corrosion resistance and solderability but comes at a higher material cost driven by tin's market value. Choosing between terne plate and pure tin plate depends on balancing budget constraints with performance requirements in applications like roofing and food packaging.

Performance in Food Packaging

Terne plate, coated with a lead-tin alloy, offers superior corrosion resistance and durability compared to pure tin plate, making it ideal for heavy-duty food packaging that requires extended shelf life. Pure tin plate provides excellent non-toxicity and solderability, ensuring food safety and ease of fabrication, but it may be less resistant to mechanical damage and chemical reactions. Performance in food packaging largely depends on the packaging conditions and product type, with terne plate favored for products needing robust protection and pure tin plate preferred for direct food contact due to its safer metallic composition.

Future Trends in Tin-Based Plating Materials

Future trends in tin-based plating materials emphasize increased use of terne plate due to its superior corrosion resistance through alloying tin with lead or zinc, enhancing durability for industrial applications. Pure tin plate remains favored for its excellent solderability and non-toxicity, driving demand in electronics and food packaging sectors focused on safety and environmental compliance. Innovations in eco-friendly alloy formulations and advances in thin-film deposition technology are poised to refine performance characteristics, reducing environmental impact and expanding applications of both terne and pure tin plates.

Terne Plate vs Pure Tin Plate Infographic

materialdif.com

materialdif.com