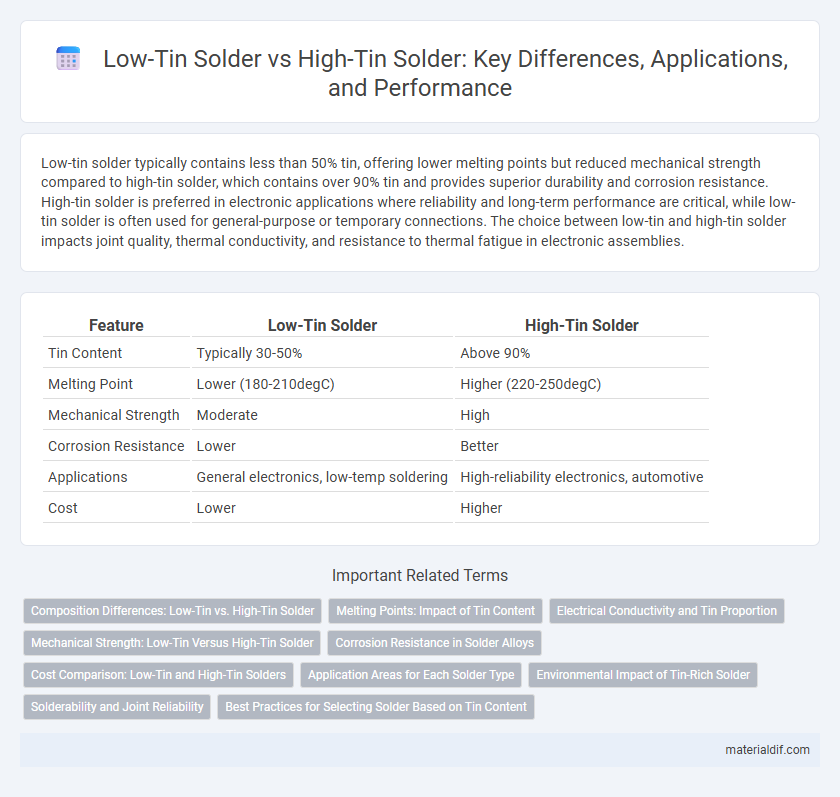

Low-tin solder typically contains less than 50% tin, offering lower melting points but reduced mechanical strength compared to high-tin solder, which contains over 90% tin and provides superior durability and corrosion resistance. High-tin solder is preferred in electronic applications where reliability and long-term performance are critical, while low-tin solder is often used for general-purpose or temporary connections. The choice between low-tin and high-tin solder impacts joint quality, thermal conductivity, and resistance to thermal fatigue in electronic assemblies.

Table of Comparison

| Feature | Low-Tin Solder | High-Tin Solder |

|---|---|---|

| Tin Content | Typically 30-50% | Above 90% |

| Melting Point | Lower (180-210degC) | Higher (220-250degC) |

| Mechanical Strength | Moderate | High |

| Corrosion Resistance | Lower | Better |

| Applications | General electronics, low-temp soldering | High-reliability electronics, automotive |

| Cost | Lower | Higher |

Composition Differences: Low-Tin vs. High-Tin Solder

Low-tin solder typically contains less than 50% tin combined with metals like lead, silver, or copper, offering a lower melting point and greater flexibility. High-tin solder generally exceeds 90% tin content, providing superior electrical conductivity, mechanical strength, and resistance to thermal fatigue. The compositional difference significantly impacts melting temperature, joint durability, and suitability for electronics manufacturing versus heavy-duty applications.

Melting Points: Impact of Tin Content

Low-tin solder usually contains around 40-60% tin, resulting in a melting point between 183degC and 238degC that allows for easier rework but may sacrifice mechanical strength. High-tin solder, with tin content of 90% or more, melts at a lower temperature near 183degC, improving wetting and electrical conductivity while offering superior joint reliability in high-temperature applications. The variation in melting points directly impacts soldering efficiency, joint integrity, and thermal stability in electronics manufacturing.

Electrical Conductivity and Tin Proportion

Low-tin solder typically contains a smaller proportion of tin, resulting in lower electrical conductivity compared to high-tin solder, which has a higher tin content that enhances its conductivity and thermal performance. High-tin solder alloys, often composed of 90% or more tin, provide superior electrical connections due to tin's inherent conductive properties, making them suitable for high-reliability electronic applications. The increased tin proportion in high-tin solder reduces resistance and improves signal transmission efficiency, critical for advanced circuit designs.

Mechanical Strength: Low-Tin Versus High-Tin Solder

High-tin solder typically exhibits superior mechanical strength compared to low-tin solder due to its enhanced grain structure and reduced brittleness. Low-tin solder, containing less than 60% tin, tends to have lower tensile strength and is more prone to fatigue under mechanical stress. High-tin solder alloys, with tin content above 90%, offer improved reliability in applications requiring robust joint integrity and resistance to thermal cycling.

Corrosion Resistance in Solder Alloys

Low-tin solder alloys generally exhibit poorer corrosion resistance compared to high-tin solder alloys, as higher tin content enhances the formation of stable intermetallic compounds that protect against oxidation. High-tin solders, often containing over 90% tin, provide superior durability in harsh environments due to their reduced susceptibility to galvanic corrosion and improved wettability on metal surfaces. Selecting high-tin solder alloys is critical for applications demanding long-term reliability and resistance to environmental degradation.

Cost Comparison: Low-Tin and High-Tin Solders

Low-tin solder generally costs less due to the cheaper availability of tin and lower manufacturing complexities, making it economical for large-scale, low-budget projects. High-tin solder, while more expensive, offers superior thermal and mechanical properties, justifying its cost in high-reliability and high-performance applications. Manufacturers must weigh the initial cost differential against long-term durability and performance benefits when choosing between low-tin and high-tin solder options.

Application Areas for Each Solder Type

Low-tin solder is commonly used in electronics assembly, particularly in applications requiring good wettability and electrical conductivity, such as circuit board manufacturing and consumer electronics repair. High-tin solder provides superior mechanical strength and is favored in plumbing, HVAC systems, and heavy-duty electrical connections where durability and thermal resistance are critical. Each solder type's tin content directly influences its melting point and mechanical properties, determining its suitability for specific industrial or household applications.

Environmental Impact of Tin-Rich Solder

Tin-rich solder, with a higher concentration of tin, significantly reduces the presence of lead and other harmful metals, making it a more environmentally friendly option than low-tin solder alloys. The use of high-tin solder minimizes toxic metal release during manufacturing and disposal, decreasing soil and water contamination risks. Moreover, tin-rich solder enhances recyclability and complies better with international regulations such as RoHS, promoting sustainable electronic waste management.

Solderability and Joint Reliability

Low-tin solder typically offers better solderability due to its lower melting point and smoother wetting properties, facilitating easier joint formation. High-tin solder enhances joint reliability by providing improved mechanical strength and resistance to thermal fatigue, essential for long-term electronic applications. Balancing tin content is crucial to optimize both solderability and joint durability in various manufacturing processes.

Best Practices for Selecting Solder Based on Tin Content

Low-tin solder typically contains less than 40% tin, offering better mechanical strength and reduced brittleness, making it suitable for applications requiring higher conductivity and durability. High-tin solder, often exceeding 60% tin content, provides lower melting points and improved wetting properties, ideal for delicate electronic components and precise soldering tasks. Selecting solder based on tin content requires balancing thermal performance, joint reliability, and component compatibility to optimize assembly quality and long-term functionality.

low-tin solder vs high-tin solder Infographic

materialdif.com

materialdif.com