Rolled tin sheets offer a uniform thickness and smooth surface ideal for creating thin, flexible metal components, whereas extruded tin rods provide dense, solid material suitable for machining and structural applications. The rolled tin sheet's malleability allows for easy shaping and stamping, while extruded rods ensure strength and durability for heavier-duty uses. Choosing between rolled sheets and extruded rods depends on the specific mechanical properties and form factors required in the tin pet manufacturing process.

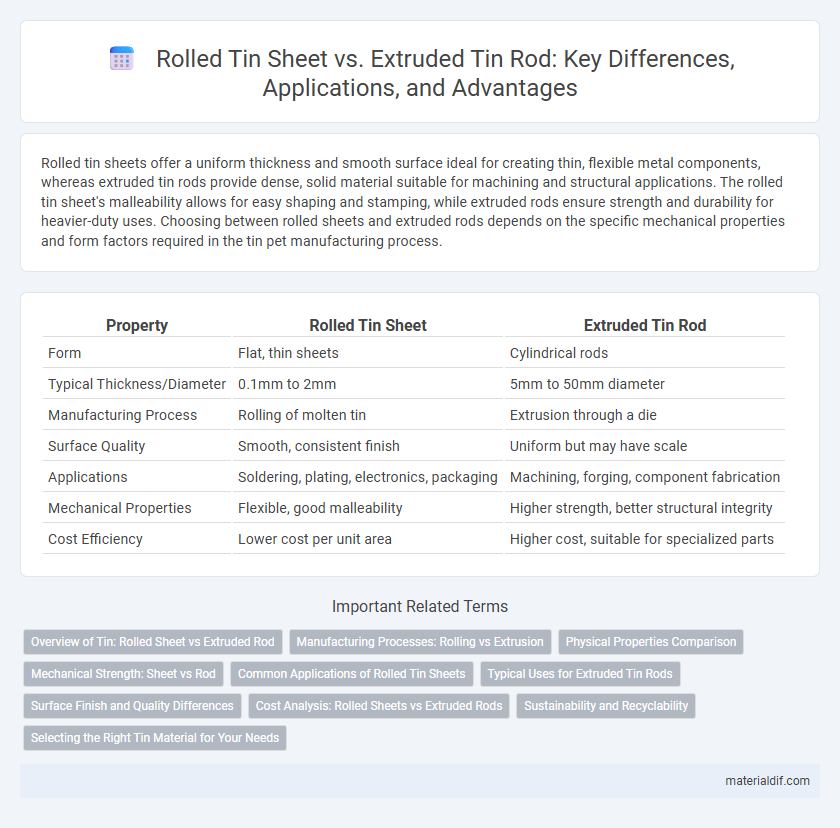

Table of Comparison

| Property | Rolled Tin Sheet | Extruded Tin Rod |

|---|---|---|

| Form | Flat, thin sheets | Cylindrical rods |

| Typical Thickness/Diameter | 0.1mm to 2mm | 5mm to 50mm diameter |

| Manufacturing Process | Rolling of molten tin | Extrusion through a die |

| Surface Quality | Smooth, consistent finish | Uniform but may have scale |

| Applications | Soldering, plating, electronics, packaging | Machining, forging, component fabrication |

| Mechanical Properties | Flexible, good malleability | Higher strength, better structural integrity |

| Cost Efficiency | Lower cost per unit area | Higher cost, suitable for specialized parts |

Overview of Tin: Rolled Sheet vs Extruded Rod

Rolled tin sheets offer a smooth, uniform surface ideal for applications in electronics and packaging, providing excellent malleability and corrosion resistance. Extruded tin rods excel in structural and industrial uses, characterized by high strength and dimensional stability due to the extrusion process. Both forms leverage tin's natural properties but differ significantly in mechanical behavior and fabrication suitability for specific manufacturing needs.

Manufacturing Processes: Rolling vs Extrusion

Rolled tin sheets are produced by passing tin slabs through rollers that compress and elongate the metal, resulting in thin, uniform sheets with precise thickness control and smooth surface finish. Extruded tin rods are formed by forcing heated tin through a die to create long, cylindrical shapes with consistent cross-sectional profiles, offering enhanced mechanical strength and structural integrity. Rolling typically provides better surface quality for sheet applications, while extrusion is preferred for complex shapes and dimensional accuracy in rod manufacturing.

Physical Properties Comparison

Rolled tin sheets exhibit a uniform thickness and smooth surface finish, making them ideal for applications requiring precise dimensional control and enhanced malleability. In contrast, extruded tin rods possess a denser and more isotropic internal structure, resulting in higher tensile strength and improved resistance to mechanical stress. The physical properties of rolled sheets favor flexibility and ductility, while extruded rods are preferred for structural components demanding greater hardness and durability.

Mechanical Strength: Sheet vs Rod

Rolled tin sheets exhibit higher tensile strength and improved ductility due to grain alignment in the rolling direction, making them ideal for applications requiring flexibility and surface coverage. Extruded tin rods typically possess greater compressive strength and uniform cross-section, suitable for load-bearing components and precision machining. Mechanical strength variations between sheets and rods stem from their distinct manufacturing processes, influencing grain structure and stress distribution.

Common Applications of Rolled Tin Sheets

Rolled tin sheets are widely used in packaging, especially for food cans and beverage containers due to their excellent corrosion resistance and malleability. They also find applications in electrical components and decorative items where thin, flexible material is essential. These sheets serve as protective coatings in the automotive and construction industries to prevent rust and extend the lifespan of metal parts.

Typical Uses for Extruded Tin Rods

Extruded tin rods are predominantly used in electronic components, soldering applications, and the manufacturing of alloy materials due to their excellent conductivity and corrosion resistance. Their high malleability and uniform composition make them ideal for precision machining and forming into intricate shapes for industrial uses. Unlike rolled tin sheets mainly utilized in packaging and coating, extruded tin rods serve critical roles in engineering and electronics where structural integrity and material purity are essential.

Surface Finish and Quality Differences

Rolled tin sheets exhibit a smooth, uniform surface finish with excellent flatness, making them ideal for applications requiring precise thickness and enhanced corrosion resistance. Extruded tin rods have a coarser surface texture due to the extrusion process, which may result in minor surface imperfections but provide superior mechanical strength and structural integrity. The choice between rolled sheets and extruded rods depends on the need for surface quality versus mechanical properties in tin-based manufacturing.

Cost Analysis: Rolled Sheets vs Extruded Rods

Rolled tin sheets generally offer a lower production cost compared to extruded tin rods due to the efficiency of the rolling process that involves less energy consumption and faster throughput. Extruded tin rods, while often providing superior mechanical properties and dimensional accuracy, typically incur higher manufacturing expenses related to specialized extrusion equipment and longer processing times. For large-scale industrial applications prioritizing cost-effectiveness, rolled tin sheets present a more economical choice, whereas extruded tin rods are favorable for precision-demanding projects despite their increased cost.

Sustainability and Recyclability

Rolled tin sheets offer superior sustainability through their efficient material utilization and minimal energy consumption during production compared to extruded tin rods, which require higher energy inputs for shaping. Both forms exhibit excellent recyclability due to tin's inherent properties, with rolled sheets often favored for closed-loop recycling in packaging industries. The choice between rolled sheets and extruded rods significantly impacts environmental performance, where rolled sheets contribute to reduced carbon footprint and enhanced material lifecycle management.

Selecting the Right Tin Material for Your Needs

Rolled tin sheets offer superior flexibility and uniform thickness, making them ideal for applications requiring precise shaping, such as electronics or packaging. Extruded tin rods provide greater structural strength and are suited for manufacturing components like connectors or fasteners that demand durability. Choose rolled tin sheets for intricate designs and extruded tin rods when mechanical stability and resilience are critical.

Rolled tin sheet vs Extruded tin rod Infographic

materialdif.com

materialdif.com