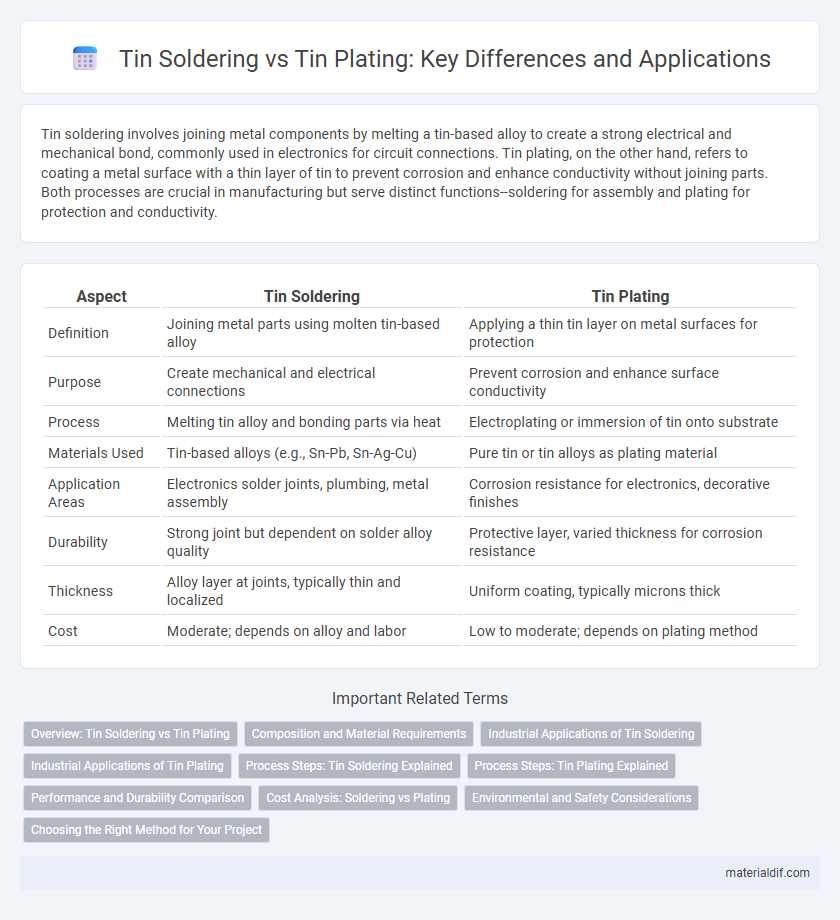

Tin soldering involves joining metal components by melting a tin-based alloy to create a strong electrical and mechanical bond, commonly used in electronics for circuit connections. Tin plating, on the other hand, refers to coating a metal surface with a thin layer of tin to prevent corrosion and enhance conductivity without joining parts. Both processes are crucial in manufacturing but serve distinct functions--soldering for assembly and plating for protection and conductivity.

Table of Comparison

| Aspect | Tin Soldering | Tin Plating |

|---|---|---|

| Definition | Joining metal parts using molten tin-based alloy | Applying a thin tin layer on metal surfaces for protection |

| Purpose | Create mechanical and electrical connections | Prevent corrosion and enhance surface conductivity |

| Process | Melting tin alloy and bonding parts via heat | Electroplating or immersion of tin onto substrate |

| Materials Used | Tin-based alloys (e.g., Sn-Pb, Sn-Ag-Cu) | Pure tin or tin alloys as plating material |

| Application Areas | Electronics solder joints, plumbing, metal assembly | Corrosion resistance for electronics, decorative finishes |

| Durability | Strong joint but dependent on solder alloy quality | Protective layer, varied thickness for corrosion resistance |

| Thickness | Alloy layer at joints, typically thin and localized | Uniform coating, typically microns thick |

| Cost | Moderate; depends on alloy and labor | Low to moderate; depends on plating method |

Overview: Tin Soldering vs Tin Plating

Tin soldering involves joining metal components using a tin-based alloy that melts at relatively low temperatures to create strong electrical and mechanical bonds. Tin plating, by contrast, is a surface treatment process where a thin layer of tin is electroplated onto a metal substrate to enhance corrosion resistance and improve solderability. Both processes utilize tin's excellent wettability and conductivity but serve distinct roles in electronics manufacturing and corrosion protection.

Composition and Material Requirements

Tin soldering primarily involves a tin-based alloy, often combined with lead, silver, or copper to achieve specific melting points and mechanical properties essential for reliable electrical connections. Tin plating employs a thin layer of pure or alloyed tin deposited onto a substrate, requiring high-purity tin to ensure corrosion resistance and excellent solderability. Materials for tin soldering demand controlled alloy compositions for melting behavior, whereas tin plating focuses on uniform coating thickness and adhesion to prevent oxidation and enhance conductivity.

Industrial Applications of Tin Soldering

Tin soldering is widely used in industrial electronics manufacturing for creating reliable electrical connections between components, ensuring strong mechanical bonds and efficient conductivity. It facilitates precise assembly of circuit boards, critical in automotive, aerospace, and consumer electronics industries due to its excellent thermal and electrical properties. Tin soldering processes optimize production speed and product durability, making it essential for high-volume manufacturing environments.

Industrial Applications of Tin Plating

Tin plating enhances corrosion resistance and electrical conductivity, making it essential in industries such as electronics, automotive, and food packaging. Its ability to provide a durable, solderable surface on steel and copper components improves performance and longevity in industrial applications. Compared to tin soldering, tin plating offers a continuous protective coating critical for mass-produced metal parts exposed to harsh environments.

Process Steps: Tin Soldering Explained

Tin soldering involves heating a tin-based alloy until it melts and forms a strong metallurgical bond between electronic components and circuit boards through specific process steps: surface cleaning to remove oxidation, precise temperature control for melting the solder alloy, and controlled cooling to solidify the joint without defects. The process requires flux application to improve wetting, soldering iron or wave soldering techniques to uniformly apply the molten tin, and meticulous inspection to ensure electrical conductivity and mechanical strength. These steps differentiate tin soldering from tin plating, which deposits a thin layer of tin on surfaces via electrochemical methods without melting or bonding components.

Process Steps: Tin Plating Explained

Tin plating involves several precise process steps, starting with surface preparation through cleaning and degreasing to ensure optimal adhesion. The substrate then undergoes electroplating in a tin salt solution, where an electric current deposits a thin, uniform layer of tin onto the metal surface. Final rinsing and drying steps prevent oxidation and enhance the protective and conductive properties of the tin coating.

Performance and Durability Comparison

Tin soldering provides strong mechanical bonds and excellent electrical conductivity, making it ideal for reliable electronic connections with moderate durability against thermal cycling. Tin plating offers superior corrosion resistance and enhanced surface protection, extending the lifespan of components in harsh environments. Performance-wise, tin soldering excels in creating robust joints, while tin plating delivers greater durability by preventing oxidation and wear.

Cost Analysis: Soldering vs Plating

Tin soldering typically incurs lower initial costs due to minimal equipment and material requirements, making it ideal for small-scale applications and repairs. Tin plating involves higher upfront expenses related to specialized baths and controlled environments but offers long-term benefits through enhanced corrosion resistance and durability. Evaluating total cost of ownership highlights soldering's cost-effectiveness for short-term projects, while plating proves economical for high-volume or prolonged use scenarios.

Environmental and Safety Considerations

Tin soldering involves melting a tin-based alloy to join metal parts, which can release flux fumes containing potentially hazardous substances like rosin or halides. Tin plating, a process of depositing a thin layer of tin onto a metal surface mainly through electroplating, generally poses fewer immediate health risks but involves the use of chemicals that require proper waste management to prevent environmental contamination. Both processes demand adherence to safety protocols and environmentally responsible disposal methods to minimize exposure to toxic substances and reduce ecological impact.

Choosing the Right Method for Your Project

Tin soldering provides strong electrical connections ideal for circuit boards and electronic components, while tin plating enhances corrosion resistance and surface conductivity on metal parts. For projects requiring durable bonds between components, tin soldering ensures reliable joint integrity, whereas tin plating is preferable for protective coatings or improving surface finish. Assess project needs such as mechanical strength, environmental exposure, and electrical requirements to determine whether tin soldering or tin plating is the optimal choice.

Tin Soldering vs Tin Plating Infographic

materialdif.com

materialdif.com