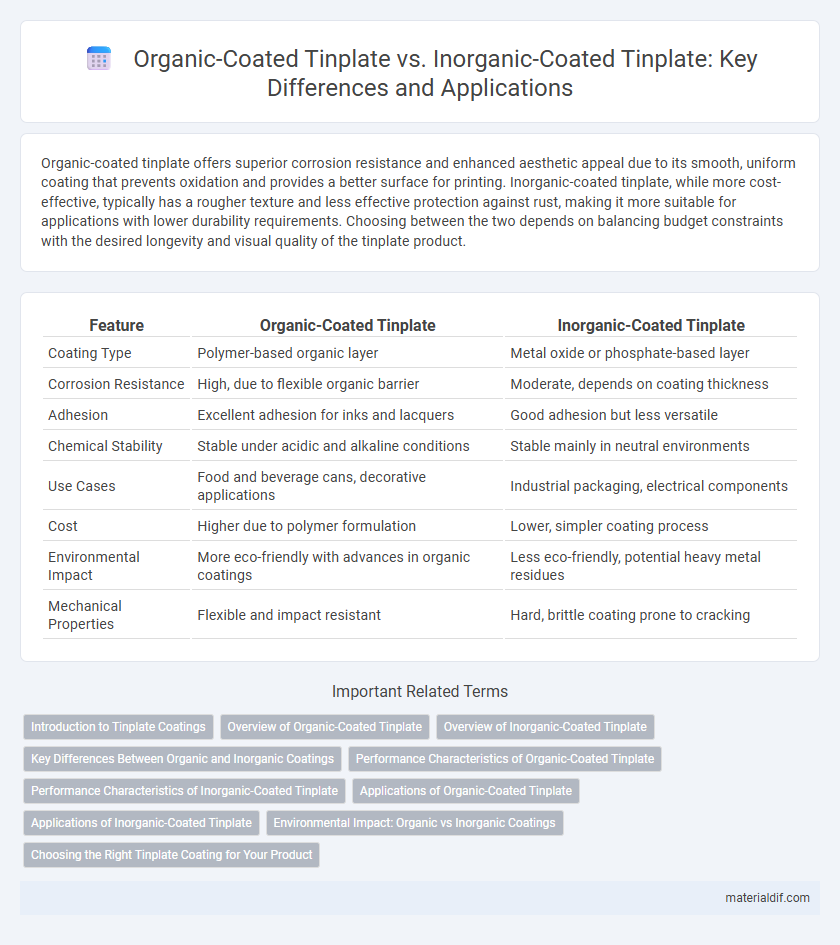

Organic-coated tinplate offers superior corrosion resistance and enhanced aesthetic appeal due to its smooth, uniform coating that prevents oxidation and provides a better surface for printing. Inorganic-coated tinplate, while more cost-effective, typically has a rougher texture and less effective protection against rust, making it more suitable for applications with lower durability requirements. Choosing between the two depends on balancing budget constraints with the desired longevity and visual quality of the tinplate product.

Table of Comparison

| Feature | Organic-Coated Tinplate | Inorganic-Coated Tinplate |

|---|---|---|

| Coating Type | Polymer-based organic layer | Metal oxide or phosphate-based layer |

| Corrosion Resistance | High, due to flexible organic barrier | Moderate, depends on coating thickness |

| Adhesion | Excellent adhesion for inks and lacquers | Good adhesion but less versatile |

| Chemical Stability | Stable under acidic and alkaline conditions | Stable mainly in neutral environments |

| Use Cases | Food and beverage cans, decorative applications | Industrial packaging, electrical components |

| Cost | Higher due to polymer formulation | Lower, simpler coating process |

| Environmental Impact | More eco-friendly with advances in organic coatings | Less eco-friendly, potential heavy metal residues |

| Mechanical Properties | Flexible and impact resistant | Hard, brittle coating prone to cracking |

Introduction to Tinplate Coatings

Organic-coated tinplate features a polymer-based layer that enhances corrosion resistance and provides superior printability, making it ideal for food and beverage packaging. Inorganic-coated tinplate typically uses chromium or oxide layers, offering excellent adhesion and chemical resistance but limited flexibility for graphic decoration. Both coatings serve critical roles in protecting the tin substrate while catering to specific industrial requirements and end-use applications.

Overview of Organic-Coated Tinplate

Organic-coated tinplate offers enhanced corrosion resistance and superior printability compared to inorganic-coated variants, making it ideal for packaging applications requiring high aesthetic appeal and durability. The organic coating, typically composed of polymer-based lacquers, provides a flexible barrier that protects the underlying steel substrate from environmental damage. This combination delivers improved adhesion for inks and coatings, ensuring longer-lasting labels and graphics on food and beverage containers.

Overview of Inorganic-Coated Tinplate

Inorganic-coated tinplate features a protective layer primarily composed of compounds like chromates or phosphates, enhancing corrosion resistance and paint adhesion without the use of organic polymers. This coating improves the metal's durability in harsh environments, making it ideal for industrial applications where longevity and chemical resistance are critical. Compared to organic-coated tinplate, inorganic coatings provide a more stable surface for subsequent processing and exhibit superior performance in high-temperature conditions.

Key Differences Between Organic and Inorganic Coatings

Organic-coated tinplate features polymer-based films that enhance corrosion resistance and provide excellent printability, making it ideal for packaging applications requiring aesthetic appeal and product protection. Inorganic-coated tinplate uses oxide or phosphate layers that offer superior heat resistance and durability but lower flexibility compared to organic coatings. These fundamental differences affect their suitability for various industrial uses, with organic coatings preferred for decorative and food packaging and inorganic coatings favored in heavy-duty or high-temperature environments.

Performance Characteristics of Organic-Coated Tinplate

Organic-coated tinplate offers superior corrosion resistance and enhanced surface protection compared to inorganic-coated variants, making it ideal for packaging applications requiring long-term durability. The organic coatings provide excellent adhesion, preventing delamination and maintaining the integrity of printed labels or decorative finishes. Furthermore, the flexibility and chemical resistance of organic-coated tinplate improve performance under mechanical stress and exposure to various food and beverage contents.

Performance Characteristics of Inorganic-Coated Tinplate

Inorganic-coated tinplate exhibits superior corrosion resistance and higher thermal stability compared to organic-coated alternatives, making it ideal for high-temperature applications such as food can manufacturing. Its oxide-based coating enhances adhesion and durability, providing improved scratch resistance and extended shelf life for packaged goods. The inorganic layer also offers better compatibility with sterilization processes, maintaining the tinplate's integrity under rigorous conditions.

Applications of Organic-Coated Tinplate

Organic-coated tinplate is widely used in food and beverage packaging due to its excellent corrosion resistance and ability to maintain product freshness. It provides superior printability and aesthetic appeal, making it ideal for consumer-facing containers like beverage cans and food tins. The organic coating also enhances chemical resistance, protecting contents from contamination and extending shelf life.

Applications of Inorganic-Coated Tinplate

Inorganic-coated tinplate is widely used in applications requiring high corrosion resistance and heat durability, such as food and beverage cans, aerosol containers, and industrial packaging. Its superior resistance to chemical reactions makes it ideal for preserving acidic or oily products, ensuring long shelf life and product safety. Industrial sectors rely on inorganic coatings for their robustness in harsh environments, including automotive and electrical components.

Environmental Impact: Organic vs Inorganic Coatings

Organic-coated tinplate typically demonstrates a lower environmental impact compared to inorganic-coated tinplate due to its reduced reliance on heavy metals and hazardous chemicals. Organic coatings often enable easier recyclability and generate less toxic waste during production and disposal. In contrast, inorganic coatings, such as those containing chromium compounds, pose greater environmental risks related to toxicity and persistent pollutants.

Choosing the Right Tinplate Coating for Your Product

Organic-coated tinplate offers superior corrosion resistance and aesthetic versatility, making it ideal for consumer goods like food cans and packaging requiring high-quality surface finishes. Inorganic-coated tinplate provides enhanced durability against harsh environments and chemical exposure, suitable for industrial applications where robust protection is critical. Selecting the right tinplate coating depends on the product's exposure conditions, required shelf life, and desired visual appeal, ensuring optimal performance and cost-efficiency.

Organic-Coated Tinplate vs Inorganic-Coated Tinplate Infographic

materialdif.com

materialdif.com