Electrolytic tinplate offers superior surface smoothness and enhanced corrosion resistance due to its precise tin coating process, making it ideal for high-quality food packaging. Hot-dipped tinplate provides a thicker, more robust tin layer, which improves durability and weldability, often preferred in industrial applications. Choosing between electrolytic and hot-dipped tinplate depends on the required balance between surface finish, corrosion resistance, and mechanical strength.

Table of Comparison

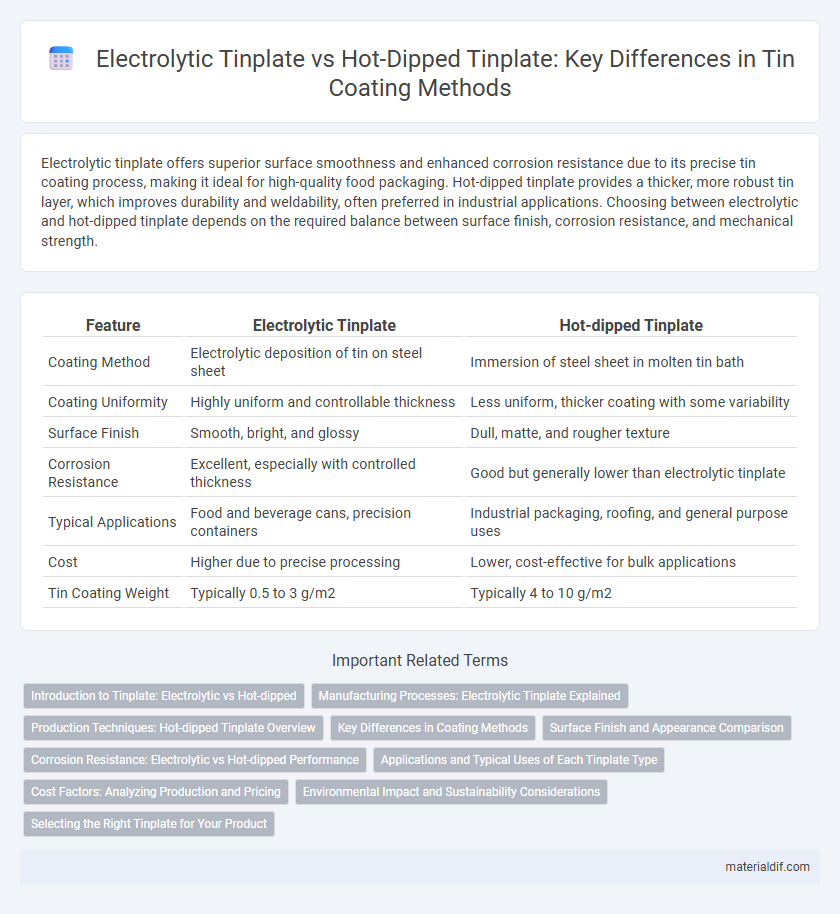

| Feature | Electrolytic Tinplate | Hot-dipped Tinplate |

|---|---|---|

| Coating Method | Electrolytic deposition of tin on steel sheet | Immersion of steel sheet in molten tin bath |

| Coating Uniformity | Highly uniform and controllable thickness | Less uniform, thicker coating with some variability |

| Surface Finish | Smooth, bright, and glossy | Dull, matte, and rougher texture |

| Corrosion Resistance | Excellent, especially with controlled thickness | Good but generally lower than electrolytic tinplate |

| Typical Applications | Food and beverage cans, precision containers | Industrial packaging, roofing, and general purpose uses |

| Cost | Higher due to precise processing | Lower, cost-effective for bulk applications |

| Tin Coating Weight | Typically 0.5 to 3 g/m2 | Typically 4 to 10 g/m2 |

Introduction to Tinplate: Electrolytic vs Hot-dipped

Electrolytic tinplate features a smooth, uniform tin coating achieved through electroplating, offering superior corrosion resistance and solderability ideal for food packaging and electronics. In contrast, hot-dipped tinplate undergoes a molten tin bath, producing a thicker layer with a rougher surface that excels in mechanical durability and cost-efficiency for general-purpose containers. The distinct manufacturing processes of electrolytic and hot-dipped tinplates result in varying tin layer characteristics, impacting their performance based on application demands.

Manufacturing Processes: Electrolytic Tinplate Explained

Electrolytic tinplate is produced by depositing a thin, uniform layer of tin onto steel sheets through an electroplating process, ensuring superior corrosion resistance and smoother surface finish compared to hot-dipped tinplate. This method uses an electrolytic bath where steel passes as the cathode, allowing precise control of tin thickness and coating quality, essential for food and beverage packaging. The controlled environment minimizes surface defects and enhances adhesion, making electrolytic tinplate optimal for high-performance, aesthetically demanding applications.

Production Techniques: Hot-dipped Tinplate Overview

Hot-dipped tinplate is produced by immersing cold-rolled steel strips into molten tin at temperatures around 250degC to 280degC, creating a robust metallurgical bond between the steel substrate and the tin coating. This process ensures a thick, uniform tin layer that offers excellent corrosion resistance and solderability, making it ideal for food packaging and industrial applications. The hot-dipping technique relies heavily on precise control of bath temperature, immersion time, and withdrawal speed to optimize coating thickness and adhesion quality.

Key Differences in Coating Methods

Electrolytic tinplate involves depositing a thin, uniform layer of tin onto the steel substrate through an electrochemical process, resulting in superior surface smoothness and corrosion resistance. Hot-dipped tinplate, on the other hand, is produced by immersing steel sheets into molten tin, creating a thicker, more robust coating with less precise thickness control and higher mechanical durability. The key differences lie in coating uniformity, adhesion strength, and the ability to tailor thickness, influencing their suitability for applications like food packaging or industrial uses.

Surface Finish and Appearance Comparison

Electrolytic tinplate features a smoother, more uniform surface finish with a bright, glossy appearance ideal for high-quality packaging applications. Hot-dipped tinplate exhibits a slightly rougher texture due to the molten tin coating process, resulting in a less reflective and more matte surface. The enhanced surface finish of electrolytic tinplate offers superior printability and corrosion resistance compared to hot-dipped tinplate.

Corrosion Resistance: Electrolytic vs Hot-dipped Performance

Electrolytic tinplate offers superior corrosion resistance due to its uniform, pure tin coating that minimizes defects and prevents substrate exposure. Hot-dipped tinplate, while thicker, often has a less consistent coating that can result in localized corrosion over time. The enhanced purity and controlled deposition process of electrolytic tinplate make it the preferred choice for high-performance applications requiring long-term corrosion protection.

Applications and Typical Uses of Each Tinplate Type

Electrolytic tinplate is commonly used in packaging applications such as food and beverage cans, offering a smooth, thin, and uniform tin coating ideal for corrosion resistance and superior printability. Hot-dipped tinplate, featuring a thicker and more irregular tin layer, is favored in industrial and automotive sectors where enhanced mechanical strength and wear resistance are critical. Both types serve distinct roles, with electrolytic tinplate excelling in consumer goods packaging and hot-dipped tinplate meeting demanding structural requirements.

Cost Factors: Analyzing Production and Pricing

Electrolytic tinplate involves higher energy consumption and specialized equipment, increasing production costs compared to hot-dipped tinplate. Hot-dipped tinplate relies on dipping steel sheets into molten tin, resulting in lower material costs but potential variability in coating thickness that can affect pricing. Market demand for precision and corrosion resistance typically drives up the price of electrolytic tinplate despite its higher production expenses.

Environmental Impact and Sustainability Considerations

Electrolytic tinplate production consumes less energy and generates lower greenhouse gas emissions compared to hot-dipped tinplate, aligning with stricter environmental regulations. Hot-dipped tinplate involves higher material usage and produces more waste, adversely affecting sustainability efforts. Advancements in recycling technologies for electrolytic tinplate further enhance its environmental benefit by minimizing raw material extraction and promoting circular economy principles.

Selecting the Right Tinplate for Your Product

Electrolytic tinplate offers a uniform and smooth coating ideal for high-quality packaging applications requiring corrosion resistance and excellent printability. Hot-dipped tinplate provides a thicker, more robust coating suitable for products exposed to harsher environments or requiring enhanced mechanical strength. Choosing between electrolytic and hot-dipped tinplate depends on factors such as product protection needs, aesthetic requirements, and processing methods like forming or welding.

Electrolytic Tinplate vs Hot-dipped Tinplate Infographic

materialdif.com

materialdif.com