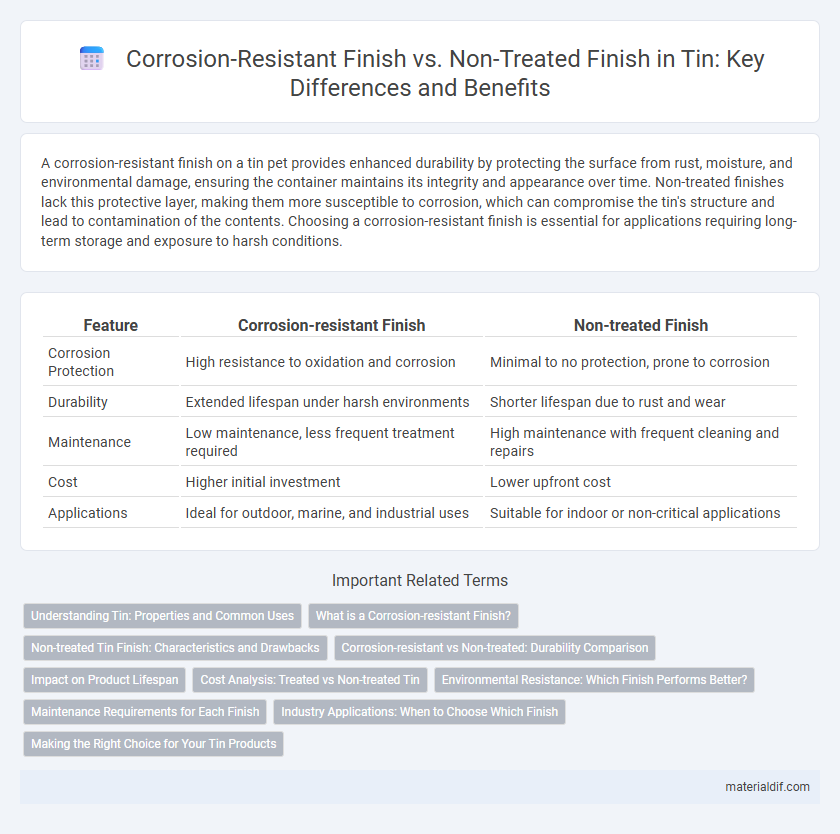

A corrosion-resistant finish on a tin pet provides enhanced durability by protecting the surface from rust, moisture, and environmental damage, ensuring the container maintains its integrity and appearance over time. Non-treated finishes lack this protective layer, making them more susceptible to corrosion, which can compromise the tin's structure and lead to contamination of the contents. Choosing a corrosion-resistant finish is essential for applications requiring long-term storage and exposure to harsh conditions.

Table of Comparison

| Feature | Corrosion-resistant Finish | Non-treated Finish |

|---|---|---|

| Corrosion Protection | High resistance to oxidation and corrosion | Minimal to no protection, prone to corrosion |

| Durability | Extended lifespan under harsh environments | Shorter lifespan due to rust and wear |

| Maintenance | Low maintenance, less frequent treatment required | High maintenance with frequent cleaning and repairs |

| Cost | Higher initial investment | Lower upfront cost |

| Applications | Ideal for outdoor, marine, and industrial uses | Suitable for indoor or non-critical applications |

Understanding Tin: Properties and Common Uses

Tin exhibits excellent corrosion resistance, making corrosion-resistant finishes ideal for preserving its metallic luster and preventing oxidation in applications such as food packaging and electronics. Non-treated tin surfaces are more susceptible to tarnishing and corrosion, which limits their durability in harsh environmental conditions. The metal's natural properties, including low toxicity and good malleability, drive its common use in coatings, soldering, and protective finishes.

What is a Corrosion-resistant Finish?

A corrosion-resistant finish on tin involves applying protective coatings or treatments that prevent oxidation and deterioration when exposed to moisture or environmental elements. This finish enhances the tin's durability and extends its lifespan by forming a barrier against rust and chemical reactions. Non-treated tin lacks this protective layer, making it more susceptible to corrosion and surface degradation over time.

Non-treated Tin Finish: Characteristics and Drawbacks

Non-treated tin finish offers basic corrosion resistance primarily through the natural oxide layer that forms on the surface, but it lacks the enhanced protective properties of corrosion-resistant finishes such as tin-lead or tin-silver alloys. This finish is prone to surface oxidation over time, leading to potential discoloration, reduced electrical conductivity, and increased susceptibility to wear in harsh environments. The lack of additional protective coatings or treatments results in vulnerability to tarnishing, making it less suitable for applications requiring long-term durability or exposure to corrosive agents.

Corrosion-resistant vs Non-treated: Durability Comparison

Corrosion-resistant tin finishes significantly enhance durability by providing a protective barrier against oxidation and environmental factors, reducing the risk of rust and material degradation over time. Non-treated tin surfaces lack this protective layer, making them more susceptible to corrosion, especially in humid or acidic environments. Consequently, corrosion-resistant finishes extend the lifespan of tin products and maintain their structural integrity better than non-treated finishes.

Impact on Product Lifespan

A corrosion-resistant finish on tin significantly extends product lifespan by preventing oxidation and surface degradation, which commonly occurs in non-treated finishes. Non-treated tin surfaces are prone to rust and wear, reducing durability and increasing the likelihood of product failure under environmental stress. Enhanced protection from corrosion-resistant coatings ensures longer-lasting performance and reduces maintenance costs over time.

Cost Analysis: Treated vs Non-treated Tin

Corrosion-resistant finished tin commands a higher upfront cost due to additional processing and materials, yet it significantly reduces long-term expenses by minimizing maintenance and replacement needs. Non-treated tin offers lower initial investment but incurs higher lifecycle costs stemming from rapid corrosion, decreased durability, and potential product failure. Cost analysis demonstrates that treated tin provides greater economic efficiency over time in environments prone to oxidation and corrosion.

Environmental Resistance: Which Finish Performs Better?

Corrosion-resistant finishes on tin provide superior protection against moisture, acids, and oxidation, significantly enhancing environmental resistance compared to non-treated finishes. Non-treated tin surfaces are more prone to rust and deterioration when exposed to harsh environmental conditions like humidity and saltwater. The enhanced durability of corrosion-resistant finishes ensures longer product lifespan and reduced maintenance costs in aggressive environments.

Maintenance Requirements for Each Finish

Corrosion-resistant tin finishes significantly reduce maintenance requirements by providing a protective barrier against oxidation and environmental exposure, extending the lifespan of metal surfaces. Non-treated tin finishes require frequent cleaning and reapplication to prevent rust and deterioration, increasing long-term upkeep efforts and costs. Selecting a corrosion-resistant finish minimizes downtime and preserves the material's structural integrity over time.

Industry Applications: When to Choose Which Finish

Corrosion-resistant tin finishes are essential in industries like electronics and food packaging where moisture and chemical exposure demand high durability and contamination prevention. Non-treated tin finishes suit applications in dry, controlled environments such as certain automotive parts or decorative items where cost-efficiency outweighs corrosion risks. Choosing the right finish depends on exposure conditions, performance requirements, and regulatory standards to ensure product longevity and safety.

Making the Right Choice for Your Tin Products

Choosing a corrosion-resistant finish for tin products extends their lifespan by protecting against rust and environmental damage, especially in humid or industrial settings. Non-treated finishes may offer a lower upfront cost but lack durability, leading to higher maintenance and replacement expenses over time. Selecting a corrosion-resistant treatment optimizes product performance and cost-efficiency in applications such as food packaging, electronics, and architectural components.

Corrosion-resistant Finish vs Non-treated Finish Infographic

materialdif.com

materialdif.com