Matte tin finish offers a subdued, non-reflective surface that reduces glare and fingerprints, ideal for a modern, understated look. Bright tin finish provides a highly reflective, polished appearance that enhances visual appeal and highlights intricate tin details. Choosing between matte and bright tin finishes depends on the desired aesthetic and functional requirements for the tin pet product.

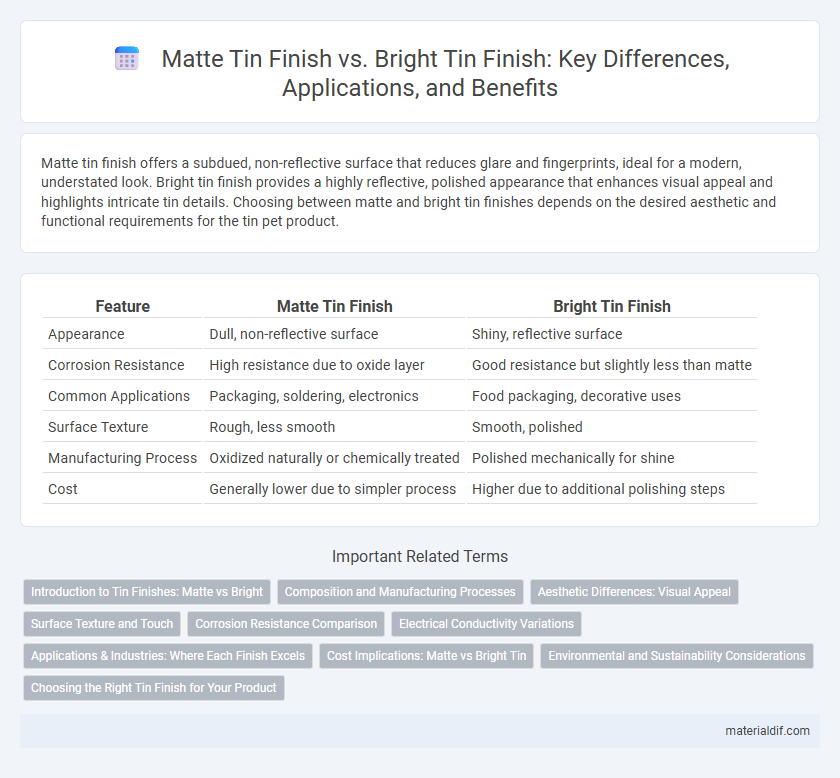

Table of Comparison

| Feature | Matte Tin Finish | Bright Tin Finish |

|---|---|---|

| Appearance | Dull, non-reflective surface | Shiny, reflective surface |

| Corrosion Resistance | High resistance due to oxide layer | Good resistance but slightly less than matte |

| Common Applications | Packaging, soldering, electronics | Food packaging, decorative uses |

| Surface Texture | Rough, less smooth | Smooth, polished |

| Manufacturing Process | Oxidized naturally or chemically treated | Polished mechanically for shine |

| Cost | Generally lower due to simpler process | Higher due to additional polishing steps |

Introduction to Tin Finishes: Matte vs Bright

Matte tin finish offers a non-reflective, dull surface that enhances grip and reduces glare, making it ideal for industrial applications requiring low friction. Bright tin finish provides a smooth, shiny, and highly reflective surface, often used in decorative or electronic applications for its aesthetic appeal and corrosion resistance. Both finishes protect the underlying metal but serve different functional and visual purposes based on their texture and reflectivity.

Composition and Manufacturing Processes

Matte tin finishes are characterized by a rougher surface achieved through processes like acid etching or chemical treatment, which modifies the tin's microstructure and reduces reflectivity. In contrast, bright tin finishes involve electroplating or mechanical polishing, producing a smooth, highly reflective surface through controlled deposition of pure tin or tin alloys. The composition for both finishes predominantly consists of high-purity tin, but bright finishes often require tighter control over alloying elements to enhance luster and corrosion resistance during manufacturing.

Aesthetic Differences: Visual Appeal

Matte tin finish offers a subdued, non-reflective surface that tends to highlight a rustic, industrial aesthetic with its soft, muted tones. Bright tin finish provides a highly reflective, glossy appearance that enhances the visual appeal by creating a sleek, polished look ideal for decorative applications. The choice between matte and bright tin finishes significantly impacts the overall ambiance, with matte finishes evoking understated elegance and bright finishes emphasizing modernity and brightness.

Surface Texture and Touch

Matte tin finish features a dull, non-reflective surface with a slightly rough texture that reduces glare and fingerprints, providing a more tactile grip. Bright tin finish offers a smooth, glossy, and highly reflective surface, delivering a sleek appearance with a slick, polished touch. The choice between matte and bright finishes affects both visual appeal and hand feel, influencing product design and user experience.

Corrosion Resistance Comparison

Matte tin finish exhibits superior corrosion resistance compared to bright tin finish due to its thicker, more uniform layer that better protects underlying metals from oxidation and moisture exposure. Bright tin finish, while aesthetically appealing with its smooth and reflective surface, tends to have a thinner coating that may allow faster initiation of corrosion under harsh environmental conditions. Industrial applications requiring extended durability in corrosive environments often prefer matte tin finishes for enhanced long-term protection.

Electrical Conductivity Variations

Matte tin finish exhibits higher surface roughness due to its microcrystalline structure, resulting in slightly reduced electrical conductivity compared to bright tin finish. Bright tin finish, characterized by its smooth and reflective surface achieved through electroplating, provides enhanced electrical conductivity because of lower contact resistance and fewer surface irregularities. These variations in electrical performance are critical for applications requiring efficient signal transmission, such as in electronic connectors and printed circuit boards.

Applications & Industries: Where Each Finish Excels

Matte tin finish excels in automotive and aerospace industries where non-reflective surfaces reduce glare and enhance aesthetic subtlety, making it ideal for instrument panels and exterior components. Bright tin finish is favored in food packaging and electronics due to its superior corrosion resistance and shiny, attractive appearance that improves product visibility and shelf appeal. Both finishes serve crucial roles: matte for functional, low-gloss applications and bright for high-visibility, protective coatings in manufacturing and consumer goods.

Cost Implications: Matte vs Bright Tin

Matte tin finish generally incurs lower production costs due to simpler processing techniques and reduced polishing requirements compared to bright tin finish, which demands extensive surface treatment to achieve its reflective quality. The enhanced aesthetic appeal of bright tin finish often justifies its higher expense for applications needing superior visual impact or corrosion resistance. Cost efficiency in matte tin makes it preferable for large-scale industrial uses where functionality outweighs appearance.

Environmental and Sustainability Considerations

Matte tin finish typically involves less chemical treatment and lower energy consumption during production, making it a more environmentally sustainable choice compared to bright tin finish, which requires additional polishing and plating processes that increase carbon emissions. Matte finishes also tend to be more durable and resistant to corrosion, reducing the frequency of replacements and waste generation. Choosing matte tin finish supports resource efficiency and minimizes environmental impact in industrial applications.

Choosing the Right Tin Finish for Your Product

Choosing the right tin finish depends on the desired aesthetic and functional properties of your product; matte tin finish offers a non-reflective, subdued appearance ideal for reducing glare and hiding surface imperfections, while bright tin finish delivers a shiny, reflective surface that enhances visual appeal and highlights product quality. Matte finishes are preferred in applications requiring subtlety and durability, such as in industrial or rustic designs, whereas bright finishes suit decorative items, packaging, and products where a polished look is essential. Consider environmental exposure, required corrosion resistance, and marketing goals when selecting between matte and bright tin finishes to ensure optimal performance and customer satisfaction.

Matte tin finish vs Bright tin finish Infographic

materialdif.com

materialdif.com