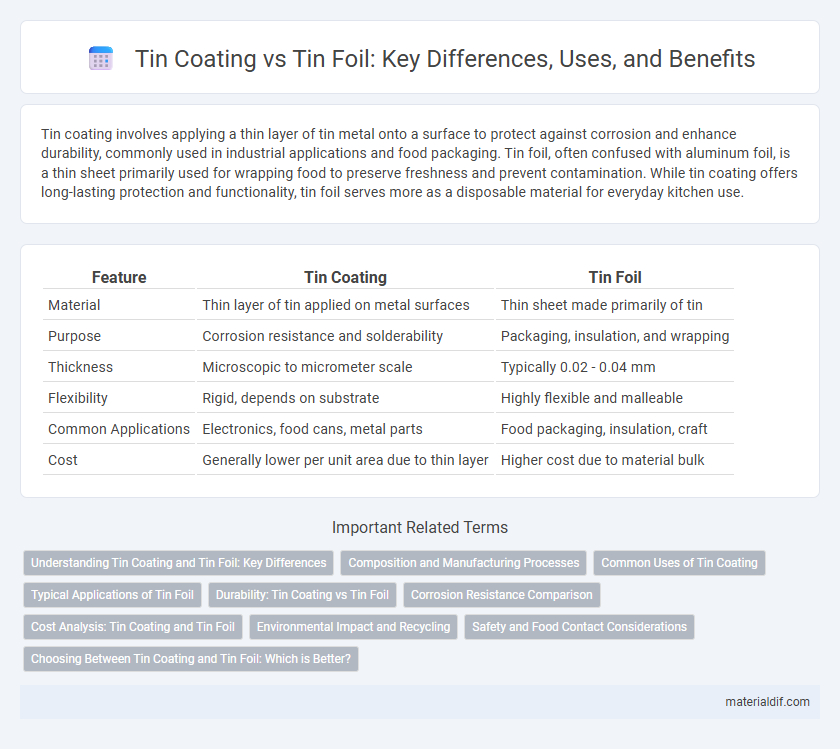

Tin coating involves applying a thin layer of tin metal onto a surface to protect against corrosion and enhance durability, commonly used in industrial applications and food packaging. Tin foil, often confused with aluminum foil, is a thin sheet primarily used for wrapping food to preserve freshness and prevent contamination. While tin coating offers long-lasting protection and functionality, tin foil serves more as a disposable material for everyday kitchen use.

Table of Comparison

| Feature | Tin Coating | Tin Foil |

|---|---|---|

| Material | Thin layer of tin applied on metal surfaces | Thin sheet made primarily of tin |

| Purpose | Corrosion resistance and solderability | Packaging, insulation, and wrapping |

| Thickness | Microscopic to micrometer scale | Typically 0.02 - 0.04 mm |

| Flexibility | Rigid, depends on substrate | Highly flexible and malleable |

| Common Applications | Electronics, food cans, metal parts | Food packaging, insulation, craft |

| Cost | Generally lower per unit area due to thin layer | Higher cost due to material bulk |

Understanding Tin Coating and Tin Foil: Key Differences

Tin coating involves applying a thin layer of tin onto metal surfaces to enhance corrosion resistance and solderability, commonly used in electronics and food packaging. Tin foil, often confused with aluminum foil, is a thin sheet of pure tin primarily utilized for wrapping food and insulation purposes. Understanding the key differences lies in their material composition, applications, and functional properties, with tin coating being a protective metal layer and tin foil serving as a malleable wrapping material.

Composition and Manufacturing Processes

Tin coating involves applying a thin layer of pure tin or tin alloys onto a substrate such as steel through electroplating or hot-dip galvanizing, which enhances corrosion resistance and solderability. Tin foil is manufactured by rolling pure tin metal into extremely thin sheets through a series of cold rolling steps, ensuring a malleable and flexible product primarily used for packaging or insulation. The differences in composition focus on tin purity and the substrates coated, while manufacturing processes diverge between metallurgical coating techniques and rolling solid metal into foil.

Common Uses of Tin Coating

Tin coating is widely used in the electronics industry for its excellent corrosion resistance and solderability, providing a protective layer on components such as connectors and printed circuit boards. It also serves as a food-safe barrier on cans, preventing contamination and extending shelf life by resisting corrosion. The automotive industry utilizes tin-coated steel to enhance durability and prevent rust in critical parts exposed to harsh environments.

Typical Applications of Tin Foil

Tin foil is primarily used in food packaging and storage due to its excellent malleability and barrier properties that protect against moisture, light, and contamination. It is widely utilized in kitchen applications for wrapping food items, lining baking trays, and preserving freshness. Industrially, tin foil serves as shielding in electronics and insulation in various manufacturing processes.

Durability: Tin Coating vs Tin Foil

Tin coating offers superior durability compared to tin foil, providing a long-lasting protective layer against corrosion and wear on metal surfaces. Unlike tin foil, which is thin and prone to tearing or deformation, tin coating forms a robust barrier that withstands mechanical stress and environmental factors. This enhanced resilience makes tin coating ideal for industrial applications requiring sustained protection and performance.

Corrosion Resistance Comparison

Tin coating offers superior corrosion resistance by forming a protective, adherent layer that prevents oxidation and metal degradation, which makes it ideal for protecting steel and other base metals. Tin foil, while composed primarily of pure tin, is thinner and more prone to mechanical damage and oxidation over time, reducing its effectiveness in long-term corrosion protection. The controlled thickness and uniformity of tin coatings applied via electroplating or hot-dipping enhance durability and resistance against environmental factors compared to tin foil.

Cost Analysis: Tin Coating and Tin Foil

Tin coating offers a cost-effective solution for applications requiring corrosion resistance and solderability, typically involving lower material expenses and longer lifespan compared to tin foil. Tin foil, often used in packaging and insulation, incurs higher material and production costs due to its thinness and processing requirements. Evaluating total lifecycle costs favors tin coating in industrial uses, while tin foil remains cost-efficient for disposable or lightweight purposes.

Environmental Impact and Recycling

Tin coating enhances product durability by preventing corrosion, leading to extended lifespan and reduced waste. Unlike tin foil, which is thin and often contaminated with food residues, tin-coated materials are easier to recycle due to their solid metal base and lower contamination risk. Recycling tin coating reduces the need for mining new tin ore, minimizing environmental degradation and conserving natural resources.

Safety and Food Contact Considerations

Tin coating provides a safe, food-grade barrier that prevents corrosion and contamination on cookware and food packaging, ensuring compliance with FDA regulations. Tin foil, often confused with aluminum foil, is rarely used because it is less durable and prone to flaking, which can pose ingestion hazards. Properly applied tin coatings are stable and non-toxic, making them preferable for prolonged food contact safety compared to thin metal foils.

Choosing Between Tin Coating and Tin Foil: Which is Better?

Tin coating offers enhanced corrosion resistance and durability for metal surfaces, making it ideal for industrial applications and cookware. Tin foil, thinner and more flexible, excels in food packaging and insulation due to its lightweight and malleability. Choosing between tin coating and tin foil depends on whether strength and protection or flexibility and convenience are the priority.

Tin Coating vs Tin Foil Infographic

materialdif.com

materialdif.com