Lead-free solder, primarily composed of tin with silver and copper, offers a safer alternative to leaded solder by eliminating harmful lead content, reducing health and environmental risks. Leaded solder, while providing excellent electrical conductivity and ease of use, poses significant toxicity concerns and is increasingly restricted by environmental regulations such as RoHS. Choosing lead-free solder ensures compliance with modern safety standards without compromising the quality of tin-based solder joints.

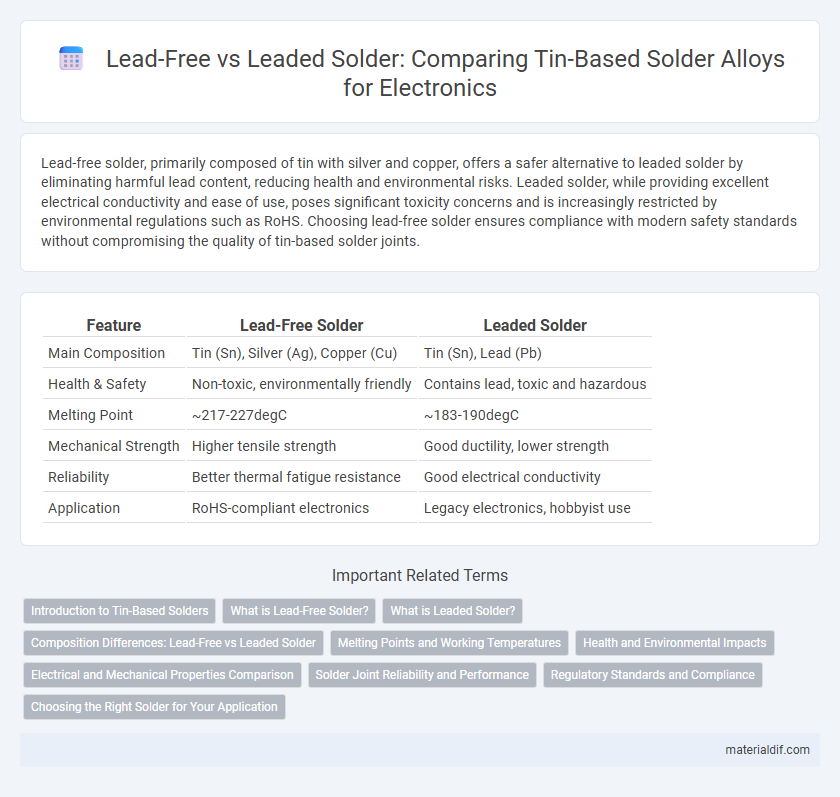

Table of Comparison

| Feature | Lead-Free Solder | Leaded Solder |

|---|---|---|

| Main Composition | Tin (Sn), Silver (Ag), Copper (Cu) | Tin (Sn), Lead (Pb) |

| Health & Safety | Non-toxic, environmentally friendly | Contains lead, toxic and hazardous |

| Melting Point | ~217-227degC | ~183-190degC |

| Mechanical Strength | Higher tensile strength | Good ductility, lower strength |

| Reliability | Better thermal fatigue resistance | Good electrical conductivity |

| Application | RoHS-compliant electronics | Legacy electronics, hobbyist use |

Introduction to Tin-Based Solders

Tin-based solders are essential in electronics for their excellent wetting properties and melting point suitable for delicate components. Lead-free solders primarily use tin combined with silver, copper, or bismuth, reducing toxicity while maintaining performance. Leaded solders, typically an alloy of tin and 60% lead, offer superior flow and mechanical strength but face restrictions due to environmental regulations.

What is Lead-Free Solder?

Lead-free solder predominantly consists of a tin base alloyed with metals like silver, copper, and bismuth to meet environmental and health regulations by eliminating toxic lead content. It offers superior corrosion resistance and complies with global standards such as RoHS, which restrict lead usage in electronic products. Lead-free solder typically melts at a higher temperature than leaded solder, requiring precise thermal management during the soldering process.

What is Leaded Solder?

Leaded solder is an alloy typically composed of tin and lead, commonly in a 60/40 or 63/37 ratio, used to join metal components due to its low melting point and excellent electrical conductivity. This type of solder offers superior wetting properties and mechanical strength compared to lead-free alternatives, making it preferred in many traditional electronics manufacturing processes. Despite its advantages, leaded solder poses environmental and health risks due to lead toxicity, prompting a shift toward lead-free solder in compliance with regulations like RoHS.

Composition Differences: Lead-Free vs Leaded Solder

Lead-free solder primarily consists of tin combined with silver, copper, or bismuth, eliminating the health hazards associated with lead toxicity. In contrast, leaded solder contains a significant portion of tin mixed with 60% lead and 40% tin, which provides a lower melting point and excellent wettability. The compositional differences directly impact soldering performance, environmental safety, and regulatory compliance in electronics manufacturing.

Melting Points and Working Temperatures

Lead-free solder, typically composed of tin, silver, and copper (SAC alloys), has a melting point around 217-220degC, which is higher than traditional leaded solder with tin and lead (Sn-Pb) that melts between 183-190degC. The elevated melting point of lead-free tin-based solders demands higher working temperatures, usually between 235-250degC, compared to the lower working temperatures of 200-230degC for leaded solder. These differences impact manufacturing processes, requiring adjustments in thermal profiles to prevent component damage and ensure proper joint formation.

Health and Environmental Impacts

Lead-free solder, primarily composed of tin combined with silver, copper, or bismuth, significantly reduces health risks associated with lead exposure such as neurotoxicity and developmental issues. Leaded solder, containing up to 40% lead, poses substantial environmental hazards due to lead toxicity, contaminating soil and water and causing bioaccumulation in ecosystems. Transitioning to lead-free tin-based solders aligns with RoHS directives, minimizing hazardous waste and promoting safer manufacturing practices.

Electrical and Mechanical Properties Comparison

Lead-free solder typically composed of tin, silver, and copper alloys exhibits higher melting points and enhanced mechanical strength compared to traditional tin-lead solder, which benefits electrical conductivity and thermal fatigue resistance in electronic assemblies. Tin-lead solder demonstrates superior electrical conductivity and lower melting temperatures, facilitating easier reflow and reduced thermal stress on components during soldering processes. The choice between these solders depends on the trade-off between environmental regulations favoring lead-free compositions and performance requirements prioritizing solder joint reliability and electrical efficiency.

Solder Joint Reliability and Performance

Lead-free solder, typically composed of tin, silver, and copper (SAC alloys), offers enhanced thermal fatigue resistance compared to traditional tin-lead solder, improving solder joint reliability under cyclic thermal stress. Tin-based leaded solders, generally an alloy of 60% tin and 40% lead, provide superior wetting properties and lower melting points, resulting in better initial joint formation and mechanical strength. However, lead-free solders exhibit greater long-term performance in high-temperature environments due to their higher melting points and reduced risk of thermal degradation.

Regulatory Standards and Compliance

Lead-free solder, primarily composed of tin, silver, and copper, complies with strict regulatory standards such as the Restriction of Hazardous Substances Directive (RoHS) and the Waste Electrical and Electronic Equipment (WEEE) Directive, mandating the reduction of hazardous materials in electronic products. Leaded solder, containing tin and significant lead content, faces increasing restrictions due to toxicity concerns and environmental impact, resulting in limited use in consumer electronics and a preference for lead-free alternatives to ensure compliance with international safety and environmental regulations. Compliance with these regulatory standards influences manufacturing processes, product certifications, and market acceptance within the electronics industry.

Choosing the Right Solder for Your Application

Lead-free solder, primarily composed of tin, copper, and silver, offers enhanced environmental safety and complies with RoHS regulations, making it ideal for consumer electronics and medical devices. Leaded solder, containing about 60% tin and 40% lead, provides lower melting points and superior joint reliability for high-precision industrial applications like aerospace and automotive electronics. Selecting the right solder depends on manufacturing requirements, thermal resistance, and regulatory compliance specific to your product's lifespan and operating environment.

Lead-Free Solder vs Leaded Solder (for tin-based solders) Infographic

materialdif.com

materialdif.com