Tin strips offer greater surface area and flexibility for precise applications in electronics and soldering, enabling efficient heat dissipation and even coating. Tin rods provide solid, durable material ideal for casting, machining, and structural components where strength is paramount. Choosing between tin strip and tin rod depends on whether the project prioritizes malleability and coverage or mechanical strength and stability.

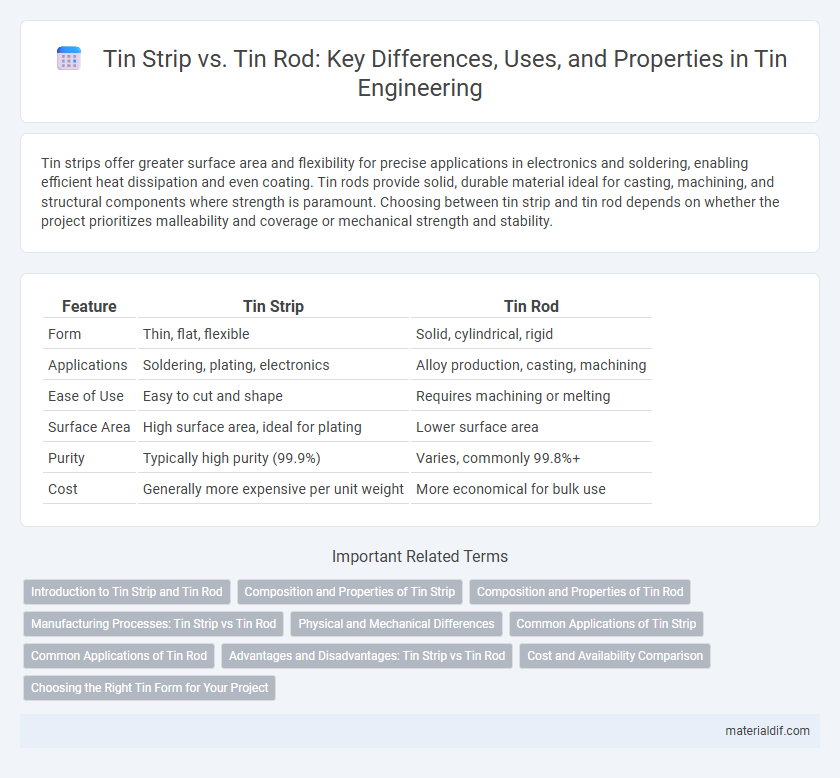

Table of Comparison

| Feature | Tin Strip | Tin Rod |

|---|---|---|

| Form | Thin, flat, flexible | Solid, cylindrical, rigid |

| Applications | Soldering, plating, electronics | Alloy production, casting, machining |

| Ease of Use | Easy to cut and shape | Requires machining or melting |

| Surface Area | High surface area, ideal for plating | Lower surface area |

| Purity | Typically high purity (99.9%) | Varies, commonly 99.8%+ |

| Cost | Generally more expensive per unit weight | More economical for bulk use |

Introduction to Tin Strip and Tin Rod

Tin strip and tin rod are two primary forms of tin used in various industrial applications, each offering distinct properties and benefits. Tin strip is a thin, flat piece of tin ideal for electronics, plating, and soldering due to its excellent malleability and corrosion resistance. Tin rod, characterized by its cylindrical shape, provides structural strength and uniformity, making it suitable for manufacturing components and alloy production.

Composition and Properties of Tin Strip

Tin strips typically consist of high-purity tin with trace amounts of copper or silver to enhance flexibility and corrosion resistance, while tin rods often have a more uniform composition with fewer additives. The composition of tin strips allows for superior malleability and excellent surface finish, making them ideal for soldering and plating applications. Their fine grain structure provides enhanced mechanical strength and resistance to oxidation compared to tin rods.

Composition and Properties of Tin Rod

Tin rods typically consist of nearly pure tin with a minimum purity of 99.8%, ensuring excellent corrosion resistance and high malleability for various manufacturing applications. Their uniform composition provides superior electrical conductivity and solderability compared to tin strips, which may contain alloying elements or coatings. The mechanical strength and ductility of tin rods make them ideal for precision machining and metallurgical processes requiring consistent material properties.

Manufacturing Processes: Tin Strip vs Tin Rod

Tin strips are typically produced through a continuous casting process followed by cold rolling, which results in thin, flat sheets used in electronics and packaging industries. Tin rods are manufactured by hot extrusion or continuous casting processes, creating cylindrical shapes suited for soldering and alloy production. The cold rolling in strip manufacturing enhances surface finish and dimensional accuracy, whereas rod production emphasizes mechanical strength and uniformity.

Physical and Mechanical Differences

Tin strips exhibit higher surface area and improved flexibility compared to tin rods due to their thin, flat shape, making them suitable for applications requiring easy bending and precise layering. Tin rods possess greater mechanical strength and rigidity, attributed to their larger cross-sectional area and solid cylindrical form, which is ideal for structural and load-bearing uses. Physically, tin strips have faster heat dissipation and quicker cooling rates, while tin rods maintain thermal stability over extended periods.

Common Applications of Tin Strip

Tin strip is widely used in electronics manufacturing for components like connectors, circuit boards, and soldering due to its excellent conductivity and corrosion resistance, making it ideal for precision applications. It also serves as a protective coating for steel in food packaging and automotive industries, enhancing durability and preventing rust. Unlike tin rods, tin strips offer greater flexibility and ease of fabrication, which makes them preferable for mass production in electrical and industrial sectors.

Common Applications of Tin Rod

Tin rods are widely used in the manufacturing of electronics, such as soldering components on printed circuit boards due to their excellent conductivity and corrosion resistance. They are also essential in the production of tin plating, providing a protective coating on steel surfaces to prevent rusting in automotive and packaging industries. Common applications extend to the fabrication of alloys like bronze and solder, where tin rods offer precise control over composition and durability.

Advantages and Disadvantages: Tin Strip vs Tin Rod

Tin strips offer superior flexibility and ease of use in applications requiring bending or shaping, making them ideal for intricate manufacturing processes. Tin rods provide higher structural strength and are better suited for applications demanding durability and resistance to deformation. However, tin strips may lack the rigidity of rods, while rods can be less adaptable and more challenging to manipulate in tight or complex designs.

Cost and Availability Comparison

Tin strips typically offer more cost-effective solutions due to their easier integration into manufacturing processes and lower material waste compared to tin rods. Tin rods, while generally more expensive, provide higher availability in specialized alloys and sizes crucial for precision applications. The choice between tin strip and tin rod depends largely on volume requirements, budget constraints, and specific industry demands, influencing overall procurement strategy.

Choosing the Right Tin Form for Your Project

Tin strips offer precise thickness and width control, making them ideal for applications requiring detailed soldering and plating. Tin rods provide greater volume and structural stability, suitable for casting, machining, and bulk manufacturing processes. Selecting the right tin form depends on the project's requirements for surface area coverage, mechanical strength, and ease of handling.

Tin strip vs Tin rod Infographic

materialdif.com

materialdif.com