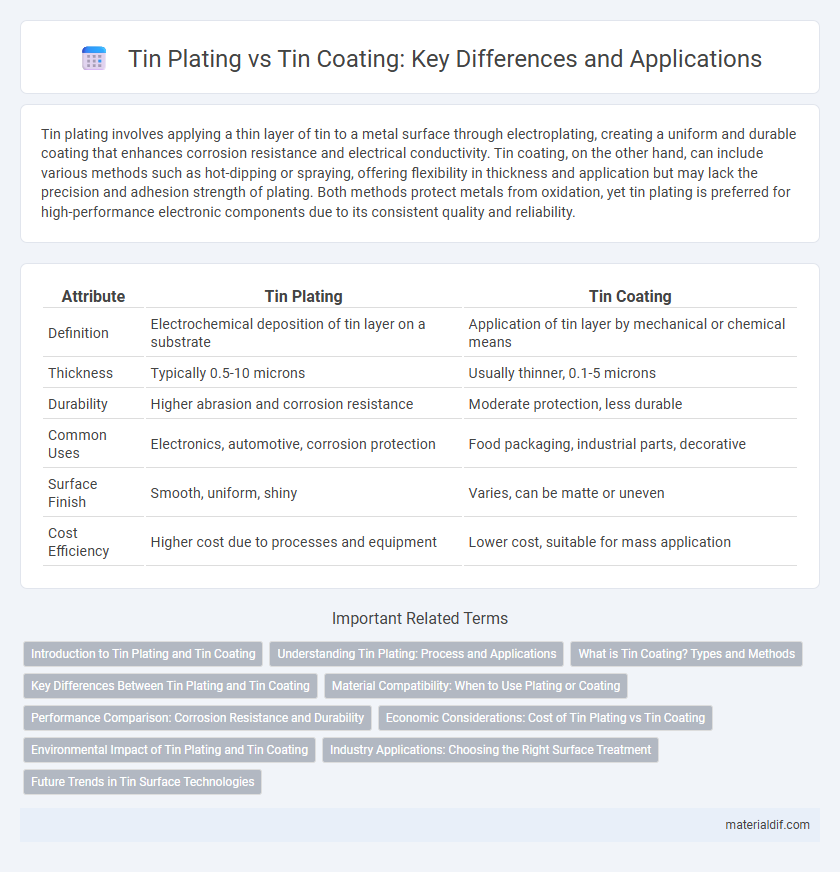

Tin plating involves applying a thin layer of tin to a metal surface through electroplating, creating a uniform and durable coating that enhances corrosion resistance and electrical conductivity. Tin coating, on the other hand, can include various methods such as hot-dipping or spraying, offering flexibility in thickness and application but may lack the precision and adhesion strength of plating. Both methods protect metals from oxidation, yet tin plating is preferred for high-performance electronic components due to its consistent quality and reliability.

Table of Comparison

| Attribute | Tin Plating | Tin Coating |

|---|---|---|

| Definition | Electrochemical deposition of tin layer on a substrate | Application of tin layer by mechanical or chemical means |

| Thickness | Typically 0.5-10 microns | Usually thinner, 0.1-5 microns |

| Durability | Higher abrasion and corrosion resistance | Moderate protection, less durable |

| Common Uses | Electronics, automotive, corrosion protection | Food packaging, industrial parts, decorative |

| Surface Finish | Smooth, uniform, shiny | Varies, can be matte or uneven |

| Cost Efficiency | Higher cost due to processes and equipment | Lower cost, suitable for mass application |

Introduction to Tin Plating and Tin Coating

Tin plating involves the electrochemical deposition of a thin layer of tin onto metal surfaces to enhance corrosion resistance and solderability. Tin coating refers to the application of tin through mechanical or thermal processes, such as hot-dipping or spraying, providing protective and functional layers on substrates. Both methods improve metal durability, with plating offering precise control over thickness and coating enabling thicker, more uniform coverage.

Understanding Tin Plating: Process and Applications

Tin plating involves electrochemically depositing a thin layer of tin onto a metal surface, enhancing corrosion resistance and solderability in electronics and automotive industries. This process ensures uniform coating thickness and strong adhesion, crucial for protecting steel parts from rust and improving electrical conductivity. Applications of tin plating include printed circuit boards, food packaging, and appliance components where durability and safety are paramount.

What is Tin Coating? Types and Methods

Tin coating is a protective layer of tin applied to metal surfaces to enhance corrosion resistance and improve solderability, commonly used in the electronics and food packaging industries. Types of tin coatings include electroplated tin, where tin is deposited using an electrical current, and hot-dip tinning, involving immersion of the metal into molten tin for a uniform layer. Methods such as mechanical plating and chemical (electroless) tin plating provide additional options to achieve specific thicknesses and adhesion properties based on application requirements.

Key Differences Between Tin Plating and Tin Coating

Tin plating involves electrochemical deposition of a thin layer of tin onto a metal surface, providing corrosion resistance and enhanced solderability. Tin coating generally refers to any method of applying tin, including mechanical or chemical processes, which may result in a thicker or more uneven layer. The key differences lie in application techniques, layer uniformity, adhesion quality, and typical uses in electronics versus industrial equipment.

Material Compatibility: When to Use Plating or Coating

Tin plating is ideal for electronic components requiring excellent solderability and corrosion resistance on compatible metals like copper and steel, providing a uniform metallic layer through electrochemical deposition. Tin coating suits applications focused on lightweight protection and easy application on diverse substrates such as aluminum or plastic, often applied via spraying or brushing methods. Selecting between tin plating and tin coating depends on the base material's compatibility with electroplated tin and the desired mechanical and environmental performance.

Performance Comparison: Corrosion Resistance and Durability

Tin plating provides superior corrosion resistance by forming a uniform, thin metallic layer that prevents substrate oxidation, whereas tin coating often involves a thicker but less consistent protective layer. Performance testing shows tin plating exhibits enhanced durability under mechanical stress and environmental exposure, maintaining conductivity and adhesion longer than conventional tin coatings. Industrial applications prefer tin plating for electronics and food packaging due to its reliably high corrosion resistance and prolonged service life.

Economic Considerations: Cost of Tin Plating vs Tin Coating

Tin plating generally incurs higher costs due to the electrochemical processes and equipment required, whereas tin coating, often applied via simpler mechanical or chemical methods, tends to be more economical for large-scale production. The cost-effectiveness of tin coating makes it a preferred choice in applications where budget constraints outweigh the need for the enhanced durability and corrosion resistance provided by tin plating. Evaluating total lifecycle expenses, including maintenance and longevity, is crucial for determining the more cost-efficient option between tin plating and tin coating.

Environmental Impact of Tin Plating and Tin Coating

Tin plating involves electrochemical deposition of tin onto metal surfaces, often using chemicals that can generate hazardous waste requiring careful disposal to minimize environmental pollution. Tin coating typically refers to processes like hot-dipping, which use molten tin and produce fewer chemical byproducts, reducing ecological risks but consuming significant energy. Both methods impact ecosystems differently, with plating risking toxic effluents and coating facing challenges related to energy consumption and resource use.

Industry Applications: Choosing the Right Surface Treatment

Tin plating provides a uniform metallic layer that enhances corrosion resistance and solderability ideal for electronic components and automotive parts. Tin coating, often applied through hot-dipping or electroplating, offers cost-effective surface protection primarily used in food packaging and steel manufacturing. Selecting between tin plating and tin coating depends on industry-specific requirements such as conductivity, durability, and environmental exposure.

Future Trends in Tin Surface Technologies

Emerging trends in tin surface technologies emphasize advanced tin plating techniques that enhance corrosion resistance and electrical conductivity for automotive and electronics industries. Innovations in eco-friendly, lead-free tin coatings address stringent environmental regulations while improving solderability on circuit boards. Future developments prioritize nanostructured tin layers and hybrid coatings to optimize durability and performance in demanding industrial applications.

Tin plating vs tin coating Infographic

materialdif.com

materialdif.com