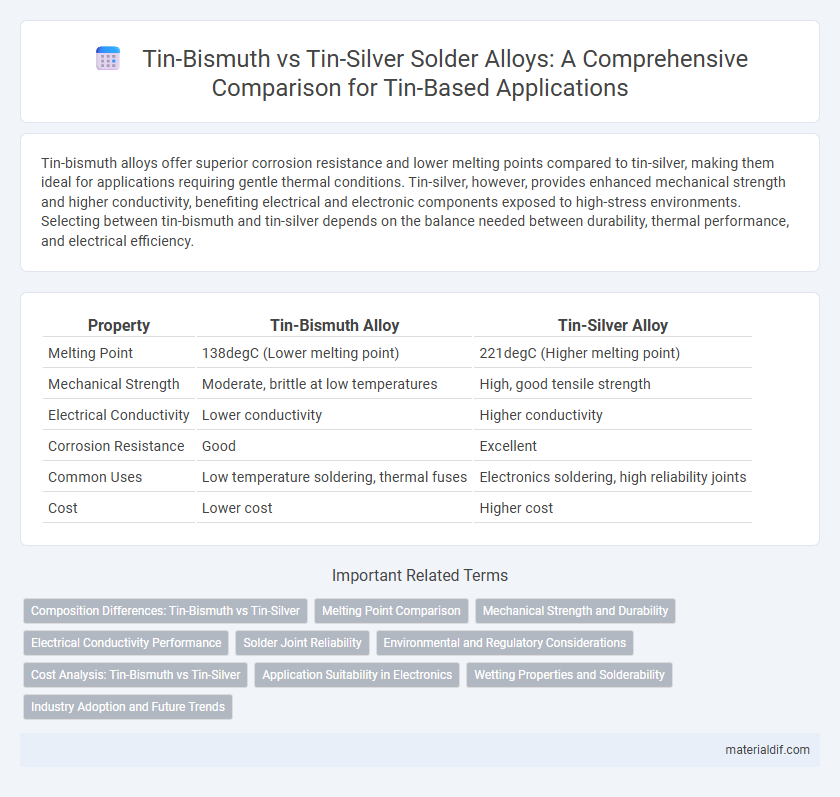

Tin-bismuth alloys offer superior corrosion resistance and lower melting points compared to tin-silver, making them ideal for applications requiring gentle thermal conditions. Tin-silver, however, provides enhanced mechanical strength and higher conductivity, benefiting electrical and electronic components exposed to high-stress environments. Selecting between tin-bismuth and tin-silver depends on the balance needed between durability, thermal performance, and electrical efficiency.

Table of Comparison

| Property | Tin-Bismuth Alloy | Tin-Silver Alloy |

|---|---|---|

| Melting Point | 138degC (Lower melting point) | 221degC (Higher melting point) |

| Mechanical Strength | Moderate, brittle at low temperatures | High, good tensile strength |

| Electrical Conductivity | Lower conductivity | Higher conductivity |

| Corrosion Resistance | Good | Excellent |

| Common Uses | Low temperature soldering, thermal fuses | Electronics soldering, high reliability joints |

| Cost | Lower cost | Higher cost |

Composition Differences: Tin-Bismuth vs Tin-Silver

Tin-bismuth alloys generally consist of approximately 58-62% tin and 38-42% bismuth, offering a low melting point ideal for soldering applications requiring reduced thermal stress. Tin-silver alloys typically contain about 96-98% tin with 2-4% silver, providing enhanced mechanical strength and thermal fatigue resistance. The presence of bismuth lowers melting temperature significantly, while silver improves joint reliability and conductivity in electronic assemblies.

Melting Point Comparison

Tin-bismuth alloys typically have a lower melting point ranging from 138degC to 145degC, making them suitable for low-temperature soldering applications. In contrast, tin-silver alloys melt at a higher temperature, generally between 217degC and 221degC, which provides enhanced thermal stability in electronic assemblies. This melting point difference directly influences the selection of these alloys based on the thermal requirements of soldering processes.

Mechanical Strength and Durability

Tin-bismuth alloys exhibit lower mechanical strength compared to tin-silver alloys, making them less suitable for high-stress applications. Tin-silver alloys offer superior durability and enhanced resistance to fatigue and wear, critical for prolonged use in electronic solder joints. The higher tensile strength of tin-silver composites ensures better performance under mechanical strain and thermal cycling.

Electrical Conductivity Performance

Tin-silver alloys exhibit higher electrical conductivity compared to tin-bismuth due to the superior electron mobility in silver, which enhances conductive pathways. Tin-bismuth alloys tend to have lower conductivity because bismuth atoms disrupt the metallic lattice, increasing electrical resistance. Consequently, tin-silver is preferred in applications requiring optimal electrical performance, such as high-reliability soldering in electronics.

Solder Joint Reliability

Tin-bismuth solder alloys offer improved resistance to thermal fatigue compared to tin-silver, enhancing solder joint reliability in cyclic temperature environments. The lower melting point of tin-bismuth reduces thermal stress during reflow, minimizing crack formation and extending joint lifespan. Tin-silver alloys provide higher tensile strength but may suffer from increased brittleness, affecting long-term reliability under mechanical strain.

Environmental and Regulatory Considerations

Tin-bismuth alloys present a lower environmental impact due to the non-toxic nature of bismuth, making them preferable under stringent regulations like RoHS and REACH focused on reducing hazardous substances. Tin-silver alloys, while offering superior mechanical properties, face stricter scrutiny because silver mining and processing contribute to higher ecological footprints and potential regulatory challenges. Compliance with global environmental standards favors tin-bismuth for sustainable electronics manufacturing, while tin-silver requires careful lifecycle assessment to mitigate environmental concerns.

Cost Analysis: Tin-Bismuth vs Tin-Silver

Tin-bismuth alloys generally offer a lower cost profile compared to tin-silver due to the abundant availability and lower price of bismuth relative to silver. The price volatility of silver significantly impacts the overall cost of tin-silver solder, making it less economical for large-scale applications. Cost efficiency in tin-bismuth makes it a preferred option for budget-sensitive manufacturing processes without compromising essential soldering performance.

Application Suitability in Electronics

Tin-bismuth alloys offer excellent low-temperature soldering capabilities, making them highly suitable for sensitive electronic components requiring minimal thermal stress. Tin-silver alloys provide superior mechanical strength and thermal fatigue resistance, ideal for high-reliability applications in automotive and aerospace electronics. Selecting between tin-bismuth and tin-silver depends on balancing factors such as melting point, joint durability, and electrical conductivity for specific electronic assembly requirements.

Wetting Properties and Solderability

Tin-bismuth alloys exhibit superior wetting properties on various metal surfaces compared to tin-silver alloys, resulting in enhanced solderability for electronic components requiring lower melting points. The lower surface tension of tin-bismuth facilitates quicker spreading and stronger metallurgical bonds on copper and nickel substrates. In contrast, tin-silver alloys offer improved mechanical strength but exhibit slower wetting kinetics and slightly reduced solderability in fine-pitch applications.

Industry Adoption and Future Trends

Tin-bismuth alloys are widely adopted in the electronics industry due to their low melting point and excellent thermal conductivity, making them ideal for lead-free soldering in consumer electronics and automotive applications. Tin-silver alloys, favored for their superior mechanical strength and thermal fatigue resistance, dominate high-reliability sectors such as aerospace and telecommunications. Future trends indicate increased use of tin-bismuth compositions in mass-market applications driven by cost efficiency and environmental compliance, while tin-silver alloys are expected to evolve with enhanced nano-additives to meet stricter performance standards.

tin-bismuth vs tin-silver Infographic

materialdif.com

materialdif.com