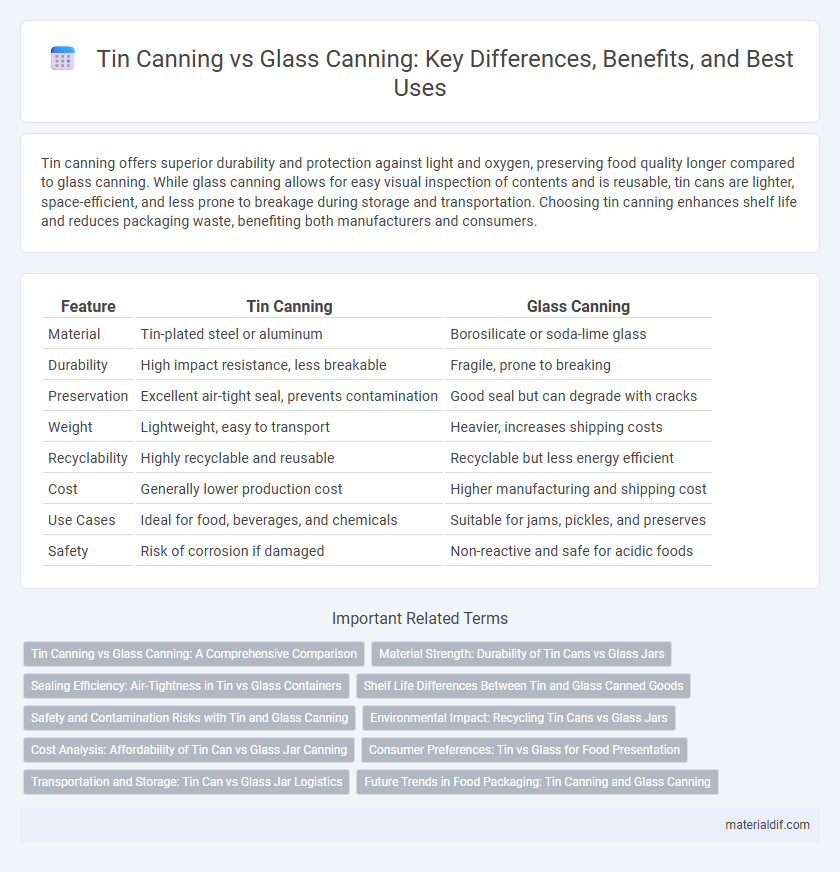

Tin canning offers superior durability and protection against light and oxygen, preserving food quality longer compared to glass canning. While glass canning allows for easy visual inspection of contents and is reusable, tin cans are lighter, space-efficient, and less prone to breakage during storage and transportation. Choosing tin canning enhances shelf life and reduces packaging waste, benefiting both manufacturers and consumers.

Table of Comparison

| Feature | Tin Canning | Glass Canning |

|---|---|---|

| Material | Tin-plated steel or aluminum | Borosilicate or soda-lime glass |

| Durability | High impact resistance, less breakable | Fragile, prone to breaking |

| Preservation | Excellent air-tight seal, prevents contamination | Good seal but can degrade with cracks |

| Weight | Lightweight, easy to transport | Heavier, increases shipping costs |

| Recyclability | Highly recyclable and reusable | Recyclable but less energy efficient |

| Cost | Generally lower production cost | Higher manufacturing and shipping cost |

| Use Cases | Ideal for food, beverages, and chemicals | Suitable for jams, pickles, and preserves |

| Safety | Risk of corrosion if damaged | Non-reactive and safe for acidic foods |

Tin Canning vs Glass Canning: A Comprehensive Comparison

Tin canning offers superior durability and protection against light and oxygen, preserving food quality longer compared to glass canning. While glass canning enables easy visual inspection and reuse, tin cans provide better resistance to breakage and are lighter for transportation. Both methods have specific advantages, but tin canning is often preferred for mass production and extended shelf life.

Material Strength: Durability of Tin Cans vs Glass Jars

Tin cans offer superior material strength compared to glass jars, providing enhanced durability against impacts and pressure changes during transportation and storage. Their resistance to shattering and deformation makes them ideal for preserving food integrity in harsh conditions. Glass jars, although chemically inert, are more prone to breakage and require careful handling to avoid damage.

Sealing Efficiency: Air-Tightness in Tin vs Glass Containers

Tin cans provide superior sealing efficiency due to their airtight metal construction, effectively preventing oxygen and moisture ingress that can compromise food preservation. Glass containers, while offering excellent chemical inertness, rely heavily on gasket seals that may deteriorate over time and potentially allow air leakage. The inherent impermeability of tin cans ensures longer shelf life and robust protection against contamination compared to typical glass canning methods.

Shelf Life Differences Between Tin and Glass Canned Goods

Shelf life differences between tin and glass canned goods hinge on their material properties affecting preservation. Tin cans provide an effective barrier against light and oxygen, minimizing oxidation and extending shelf life typically up to 2-5 years. Glass cans, although inert and non-reactive, expose contents to light unless tinted, potentially reducing shelf life to around 1-3 years due to light-induced degradation.

Safety and Contamination Risks with Tin and Glass Canning

Tin canning offers robust protection against physical damage and light exposure, reducing the risk of product spoilage, yet it poses potential safety concerns due to possible tin leaching and corrosion if the can lining is compromised. Glass canning provides a non-reactive, inert barrier that eliminates risks of metal contamination, ensuring higher purity and safety of preserved foods, but it is vulnerable to breakage, which can lead to contamination from shattered glass shards. Both methods require stringent quality controls: tin cans depend on effective lining technologies to prevent chemical contamination, while glass containers necessitate careful handling to maintain integrity and prevent microbial ingress.

Environmental Impact: Recycling Tin Cans vs Glass Jars

Recycling tin cans requires less energy compared to glass jars, reducing overall carbon emissions and conserving natural resources. Tin cans are highly recyclable, with around 70-90% recycling rates, and can be processed repeatedly without loss of quality. Glass jars, while also recyclable, demand higher melting temperatures, leading to increased energy consumption and environmental footprint in recycling facilities.

Cost Analysis: Affordability of Tin Can vs Glass Jar Canning

Tin canning offers a more cost-effective solution compared to glass jar canning due to lower material and production expenses. The lightweight nature of tin reduces shipping and handling costs, enhancing affordability across the supply chain. Glass jars, while reusable and aesthetically appealing, incur higher costs from fragile packaging and energy-intensive manufacturing processes.

Consumer Preferences: Tin vs Glass for Food Presentation

Consumers often prefer tin canning for its durability and protection against light and air, which prolongs food freshness and shelf life. Glass canning is favored for its transparent presentation, allowing customers to see the product quality and enhancing visual appeal. Packaging sustainability also influences preferences, with glass perceived as more environmentally friendly despite tin's superior preservation capabilities.

Transportation and Storage: Tin Can vs Glass Jar Logistics

Tin cans offer superior durability and lightweight advantages over glass jars, significantly reducing transportation costs and minimizing the risk of breakage during transit. Their stackable design maximizes storage efficiency in warehouses and retail environments, optimizing space utilization. Glass jars, being heavier and fragile, demand more cautious handling and increase shipping expenses, often requiring additional protective packaging to ensure safe delivery.

Future Trends in Food Packaging: Tin Canning and Glass Canning

Tin canning offers superior barrier properties against light, oxygen, and contaminants, promising extended shelf life for perishable foods, while innovations in eco-friendly tin coatings enhance sustainability. Glass canning provides excellent recyclability and chemical inertness, appealing to health-conscious consumers, with trends leaning toward lightweight, shatter-resistant glass to reduce carbon footprints. Future food packaging strategies increasingly integrate smart technologies with tin and glass containers to improve traceability and product freshness.

Tin canning vs Glass canning Infographic

materialdif.com

materialdif.com