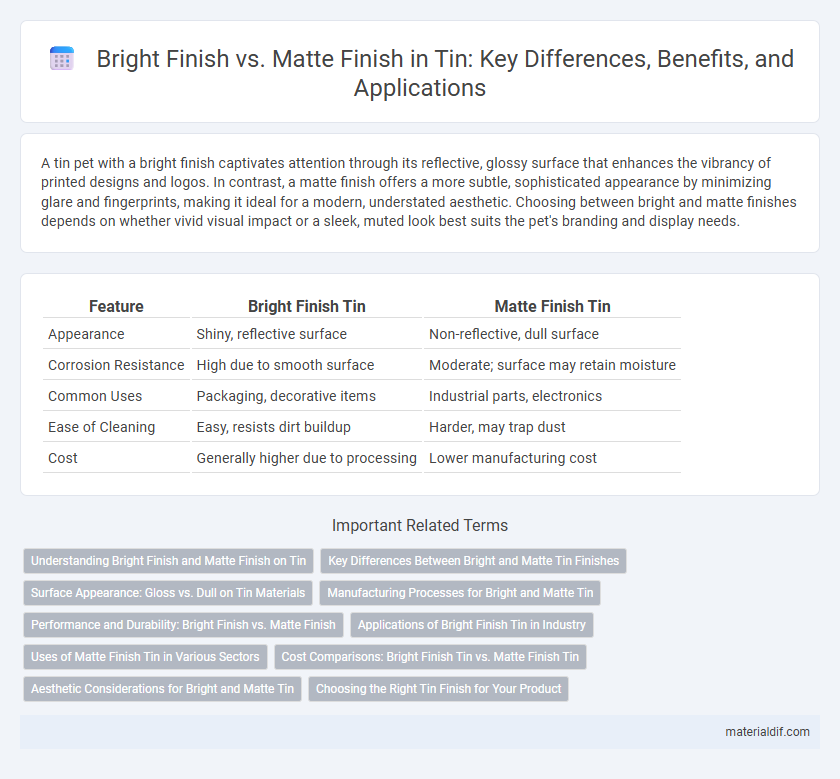

A tin pet with a bright finish captivates attention through its reflective, glossy surface that enhances the vibrancy of printed designs and logos. In contrast, a matte finish offers a more subtle, sophisticated appearance by minimizing glare and fingerprints, making it ideal for a modern, understated aesthetic. Choosing between bright and matte finishes depends on whether vivid visual impact or a sleek, muted look best suits the pet's branding and display needs.

Table of Comparison

| Feature | Bright Finish Tin | Matte Finish Tin |

|---|---|---|

| Appearance | Shiny, reflective surface | Non-reflective, dull surface |

| Corrosion Resistance | High due to smooth surface | Moderate; surface may retain moisture |

| Common Uses | Packaging, decorative items | Industrial parts, electronics |

| Ease of Cleaning | Easy, resists dirt buildup | Harder, may trap dust |

| Cost | Generally higher due to processing | Lower manufacturing cost |

Understanding Bright Finish and Matte Finish on Tin

Bright finish on tin features a highly reflective surface achieved through polishing or electroplating, enhancing corrosion resistance and aesthetic appeal in applications such as cookware and decorative items. Matte finish on tin, created by bead blasting or chemical etching, offers a non-glossy, textured surface that reduces glare and fingerprints, making it ideal for industrial use and parts requiring less visual emphasis. Choosing between bright and matte finishes depends on the desired visual effect, functional requirements, and environmental exposure of the tin product.

Key Differences Between Bright and Matte Tin Finishes

Bright tin finishes exhibit a smooth, shiny surface that enhances reflectivity and corrosion resistance, making them suitable for decorative and protective applications. Matte tin finishes feature a non-reflective, subdued texture that reduces glare and hides fingerprints, ideal for industrial uses where appearance is secondary. Both finishes offer distinct benefits in durability and aesthetics, influencing their selection based on functional and visual requirements.

Surface Appearance: Gloss vs. Dull on Tin Materials

Tin surfaces with a bright finish exhibit a glossy, reflective appearance that enhances visual appeal and highlights the metal's natural shine. In contrast, a matte finish on tin results in a dull, non-reflective surface that minimizes glare and fingerprints while providing a subtle, understated look. The choice between glossy and dull finishes directly affects the perceived texture and aesthetic, influencing suitability for decorative or functional applications.

Manufacturing Processes for Bright and Matte Tin

Bright finish tin is achieved through electroplating techniques that involve controlled deposition of tin ions onto a substrate, resulting in a smooth and reflective surface ideal for decorative and corrosion-resistant applications. Matte finish tin undergoes mechanical or chemical treatments such as brushing, sandblasting, or acid etching to create a textured, non-reflective surface that enhances grip and reduces glare. Both finishes require precise control of process parameters like current density, electrolyte composition, and treatment duration to ensure consistent quality in manufacturing.

Performance and Durability: Bright Finish vs. Matte Finish

Bright finish tin surfaces provide superior corrosion resistance and enhanced durability due to their smooth, reflective coating that repels moisture and contaminants more effectively. Matte finish tin, characterized by its textured, non-reflective surface, may exhibit increased surface area exposure, which can lead to faster wear and reduced resistance to environmental factors. In high-performance applications where longevity and preservation against oxidation are critical, bright finish tin is typically preferred for its resilience and ease of maintenance.

Applications of Bright Finish Tin in Industry

Bright finish tin is extensively used in the electronics industry for plating components due to its excellent solderability and corrosion resistance. The food packaging sector relies on bright finish tin-coated steel for cans, ensuring product preservation and aesthetic appeal. This finish also finds applications in decorative items and architectural elements, where a shiny, reflective surface is desired for enhanced visual impact.

Uses of Matte Finish Tin in Various Sectors

Matte finish tin is widely utilized in packaging industries due to its non-reflective surface that reduces glare and enhances product visibility. In electronics, matte finish tin coatings improve solderability and provide resistance to oxidation, ensuring durable connections. Additionally, the automotive sector favors matte finish tin for decorative trims and functional components where a subtle, refined appearance is essential.

Cost Comparisons: Bright Finish Tin vs. Matte Finish Tin

Bright finish tin typically incurs higher production costs due to the additional polishing and coating processes required to achieve its reflective surface, making it more expensive than matte finish tin. Matte finish tin, with its simpler surface treatment, generally offers cost savings in manufacturing, appealing to budget-conscious applications. The choice between bright and matte finishes depends on balancing aesthetic value against production expenses in various industrial and consumer uses.

Aesthetic Considerations for Bright and Matte Tin

Bright finish tin offers a reflective, shiny surface that enhances product visibility and creates a premium, eye-catching appeal ideal for decorative packaging and consumer goods. Matte finish tin provides a subdued, non-reflective look that emphasizes texture and subtlety, making it suitable for vintage designs and products requiring a sophisticated, understated aesthetic. Choosing between bright and matte finishes depends on desired visual impact, brand identity, and the product's target market preferences.

Choosing the Right Tin Finish for Your Product

Bright finish tin offers a highly reflective surface that enhances visual appeal and provides superior corrosion resistance, ideal for packaging where product visibility and shelf impact are crucial. Matte finish tin delivers a non-reflective, smooth texture that minimizes glare and fingerprints, making it suitable for premium products requiring a subtle, sophisticated look. Selecting the right tin finish depends on balancing aesthetic preferences, functional requirements, and brand positioning to achieve optimal product presentation.

Bright finish vs Matte finish Infographic

materialdif.com

materialdif.com