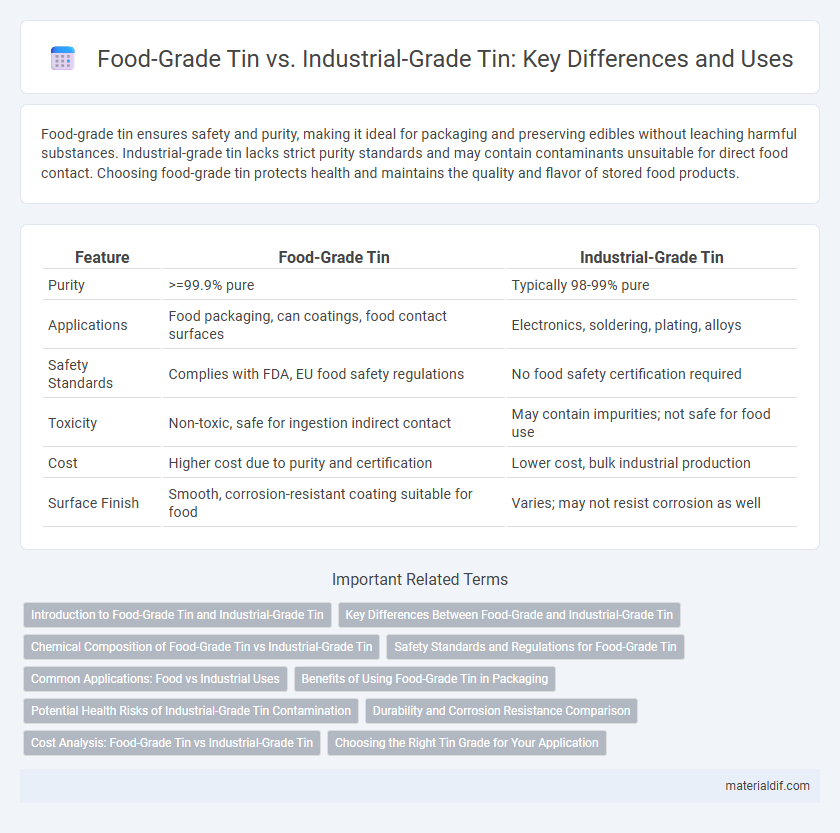

Food-grade tin ensures safety and purity, making it ideal for packaging and preserving edibles without leaching harmful substances. Industrial-grade tin lacks strict purity standards and may contain contaminants unsuitable for direct food contact. Choosing food-grade tin protects health and maintains the quality and flavor of stored food products.

Table of Comparison

| Feature | Food-Grade Tin | Industrial-Grade Tin |

|---|---|---|

| Purity | >=99.9% pure | Typically 98-99% pure |

| Applications | Food packaging, can coatings, food contact surfaces | Electronics, soldering, plating, alloys |

| Safety Standards | Complies with FDA, EU food safety regulations | No food safety certification required |

| Toxicity | Non-toxic, safe for ingestion indirect contact | May contain impurities; not safe for food use |

| Cost | Higher cost due to purity and certification | Lower cost, bulk industrial production |

| Surface Finish | Smooth, corrosion-resistant coating suitable for food | Varies; may not resist corrosion as well |

Introduction to Food-Grade Tin and Industrial-Grade Tin

Food-grade tin is specifically refined and processed to meet stringent safety standards for direct contact with consumables, ensuring it is free from harmful contaminants and suitable for packaging and preserving food and beverages. Industrial-grade tin, while also high in purity, is intended for non-food applications such as electronics, plating, and alloy production, where regulatory compliance for ingestion safety is not required. The distinction between these grades lies primarily in their chemical purity, testing protocols, and certification by food safety authorities like the FDA or EFSA.

Key Differences Between Food-Grade and Industrial-Grade Tin

Food-grade tin is characterized by its high purity, typically 99.9% or greater, ensuring it is non-toxic and safe for direct contact with food and beverages, whereas industrial-grade tin contains more impurities and is unsuitable for consumption-related applications. Food-grade tin undergoes stringent regulatory standards, such as FDA or EFSA certifications, guaranteeing it does not leach harmful substances into food products. Industrial-grade tin is primarily used in manufacturing electrical components, alloys, and coatings where food safety compliance is not required.

Chemical Composition of Food-Grade Tin vs Industrial-Grade Tin

Food-grade tin typically contains a purity level of 99.9% or higher, minimizing contaminants to ensure safety for direct contact with consumables. Industrial-grade tin may contain higher proportions of impurities such as lead, antimony, or copper, which are acceptable in manufacturing applications but unsuitable for food packaging. The strict chemical composition standards for food-grade tin prevent leaching of harmful substances, making it ideal for coatings in food containers and pharmaceutical packaging.

Safety Standards and Regulations for Food-Grade Tin

Food-grade tin complies with strict safety standards such as FDA and EFSA regulations, ensuring it is free from harmful contaminants and suitable for direct food contact. Industrial-grade tin lacks these certifications and may contain impurities or coatings that pose health risks if ingested. Compliance with food safety standards guarantees that food-grade tin prevents contamination and preserves food quality during packaging and storage.

Common Applications: Food vs Industrial Uses

Food-grade tin is primarily used for coating cans that store beverages, canned fruits, and vegetables due to its non-toxic properties and resistance to corrosion, ensuring food safety and longevity. Industrial-grade tin finds applications in soldering for electronics, plating, and manufacturing alloys, where chemical purity is less critical. The distinction in applications arises from differing purity standards, with food-grade tin meeting stringent regulations to prevent contamination, unlike its industrial counterpart.

Benefits of Using Food-Grade Tin in Packaging

Food-grade tin offers superior safety and non-toxicity, ensuring no harmful chemicals leach into food products during storage. It provides excellent corrosion resistance, maintaining the freshness and quality of packaged foods for extended shelf life. Using food-grade tin supports compliance with stringent food safety regulations and enhances consumer trust through reliable packaging integrity.

Potential Health Risks of Industrial-Grade Tin Contamination

Industrial-grade tin often contains impurities such as lead, antimony, and arsenic, which pose significant potential health risks when contaminating food products. Exposure to these toxic elements can lead to adverse effects including neurological damage, organ toxicity, and increased risk of chronic diseases. Food-grade tin undergoes strict purification processes to ensure safety by limiting heavy metal contaminants, preventing contamination and ensuring compliance with health regulations.

Durability and Corrosion Resistance Comparison

Food-grade tin offers superior corrosion resistance compared to industrial-grade tin, making it ideal for applications in direct contact with food and beverages. Its enhanced durability stems from stricter purity standards and the absence of harmful impurities found in industrial-grade tin. Industrial-grade tin, while more cost-effective, exhibits lower resistance to chemical reactions and may degrade faster in corrosive environments.

Cost Analysis: Food-Grade Tin vs Industrial-Grade Tin

Food-grade tin typically incurs higher costs due to stringent purity standards and certifications required for safe food contact, ensuring no contamination or harmful residues. Industrial-grade tin is more economical, as it allows for lower purity levels and fewer regulatory requirements, making it suitable for non-food applications. Cost analysis reveals food-grade tin can be up to 30-50% more expensive than industrial-grade tin due to these regulatory and safety measures.

Choosing the Right Tin Grade for Your Application

Food-grade tin meets stringent purity standards and is certified safe for direct contact with consumables, making it ideal for packaging, cans, and foil used in the food industry. Industrial-grade tin contains higher levels of impurities and is better suited for applications like soldering, plating, and manufacturing where direct food contact is not a concern. Selecting the appropriate tin grade depends on the application's regulatory requirements and safety standards to ensure product integrity and consumer health.

Food-grade tin vs Industrial-grade tin Infographic

materialdif.com

materialdif.com