Tin coating offers superior corrosion resistance and excellent solderability compared to organic coatings, making it ideal for electronic components and food packaging. Organic coatings provide flexibility and aesthetic customization but may degrade faster under harsh environmental conditions. Choosing tin coating ensures longer durability and enhanced protection against moisture and oxidation.

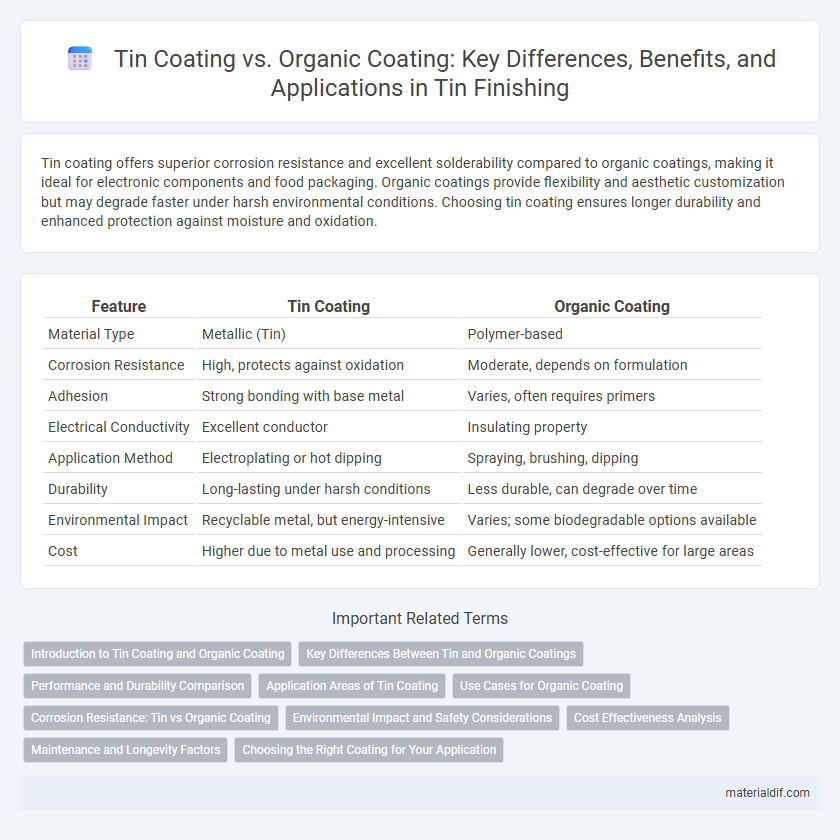

Table of Comparison

| Feature | Tin Coating | Organic Coating |

|---|---|---|

| Material Type | Metallic (Tin) | Polymer-based |

| Corrosion Resistance | High, protects against oxidation | Moderate, depends on formulation |

| Adhesion | Strong bonding with base metal | Varies, often requires primers |

| Electrical Conductivity | Excellent conductor | Insulating property |

| Application Method | Electroplating or hot dipping | Spraying, brushing, dipping |

| Durability | Long-lasting under harsh conditions | Less durable, can degrade over time |

| Environmental Impact | Recyclable metal, but energy-intensive | Varies; some biodegradable options available |

| Cost | Higher due to metal use and processing | Generally lower, cost-effective for large areas |

Introduction to Tin Coating and Organic Coating

Tin coating offers superior corrosion resistance and excellent solderability, making it ideal for electronic components and food packaging applications. Organic coating, composed of polymer-based materials, provides flexibility and enhanced protection against environmental factors such as UV radiation and moisture. Both coatings contribute to surface durability, but tin excels in electrical conductivity while organic coatings deliver customizable chemical resistance.

Key Differences Between Tin and Organic Coatings

Tin coating provides superior corrosion resistance through a metallic barrier that prevents substrate exposure, while organic coatings rely on polymer layers to protect surfaces by forming a chemical shield. Tin coatings offer excellent solderability and electrical conductivity, making them ideal for electronic components, whereas organic coatings are more versatile in color and texture, offering aesthetic and environmental protection options. The durability of tin coatings under high-temperature conditions surpasses that of organic coatings, which may degrade or lose adhesion when exposed to heat or UV radiation.

Performance and Durability Comparison

Tin coating offers superior corrosion resistance and excellent solderability, making it ideal for electronic components exposed to harsh environments. Organic coatings provide flexibility and are cost-effective but generally have lower abrasion resistance and shorter lifespan compared to tin plating. The durability of tin coatings ensures longer protection against oxidation and mechanical wear, enhancing overall performance in demanding applications.

Application Areas of Tin Coating

Tin coating is extensively applied in the food packaging industry due to its excellent corrosion resistance and non-toxicity, ensuring food safety and extending shelf life. It is also widely used in electrical components and soldering applications for its superior conductivity and strong adhesion properties. Compared to organic coatings, tin coatings provide better protection against oxidation and mechanical wear, making them ideal for metal cans, electrical connectors, and automotive parts.

Use Cases for Organic Coating

Organic coatings are widely used in industries requiring enhanced corrosion resistance and flexibility, such as automotive and electronics manufacturing. They provide superior protection against environmental factors like moisture and chemicals, making them ideal for outdoor and high-humidity applications. Unlike tin coatings, organic coatings also allow for easier repair and customization of surface properties.

Corrosion Resistance: Tin vs Organic Coating

Tin coating offers superior corrosion resistance due to its ability to form a stable, protective oxide layer that inhibits moisture and oxygen penetration, thereby preventing rust and degradation on metal surfaces. Organic coatings, while providing flexibility and aesthetic appeal, often require additional additives or frequent maintenance to maintain their protective properties against corrosive elements. The long-term durability of tin coatings in harsh environments makes them preferable for applications demanding robust corrosion protection.

Environmental Impact and Safety Considerations

Tin coating offers superior environmental benefits due to its non-toxic, recyclable properties and minimal hazardous waste generation compared to organic coatings, which often involve volatile organic compounds (VOCs) harmful to air quality and human health. The durability and corrosion resistance of tin reduce the need for frequent reapplication, lowering environmental contamination and exposure risks. Safety considerations favor tin coatings as they pose less flammability and toxicity hazards during application and disposal processes.

Cost Effectiveness Analysis

Tin coating offers superior cost-effectiveness compared to organic coatings due to its lower material and application costs combined with enhanced corrosion resistance, reducing maintenance expenses over time. Organic coatings often require frequent reapplication and may involve higher labor costs, making tin a more economical choice for long-term protection. The durability and recyclability of tin coatings further contribute to overall savings in industrial and manufacturing applications.

Maintenance and Longevity Factors

Tin coating provides superior corrosion resistance through its natural oxide layer, significantly reducing maintenance frequency compared to organic coatings that may degrade under UV exposure and require regular reapplication. Tin's durability ensures consistent protection for metal substrates in harsh environments, extending the overall lifespan of coated components. Organic coatings often demand more frequent inspections and touch-ups, impacting long-term maintenance costs and operational reliability.

Choosing the Right Coating for Your Application

Tin coating offers excellent corrosion resistance and solderability, making it ideal for electronic components and food packaging applications. Organic coatings provide superior flexibility and chemical resistance, suitable for automotive parts and outdoor equipment exposed to harsh environments. Selecting the right coating depends on factors such as exposure conditions, mechanical stress, and desired durability to ensure optimal performance and longevity.

Tin coating vs Organic coating Infographic

materialdif.com

materialdif.com