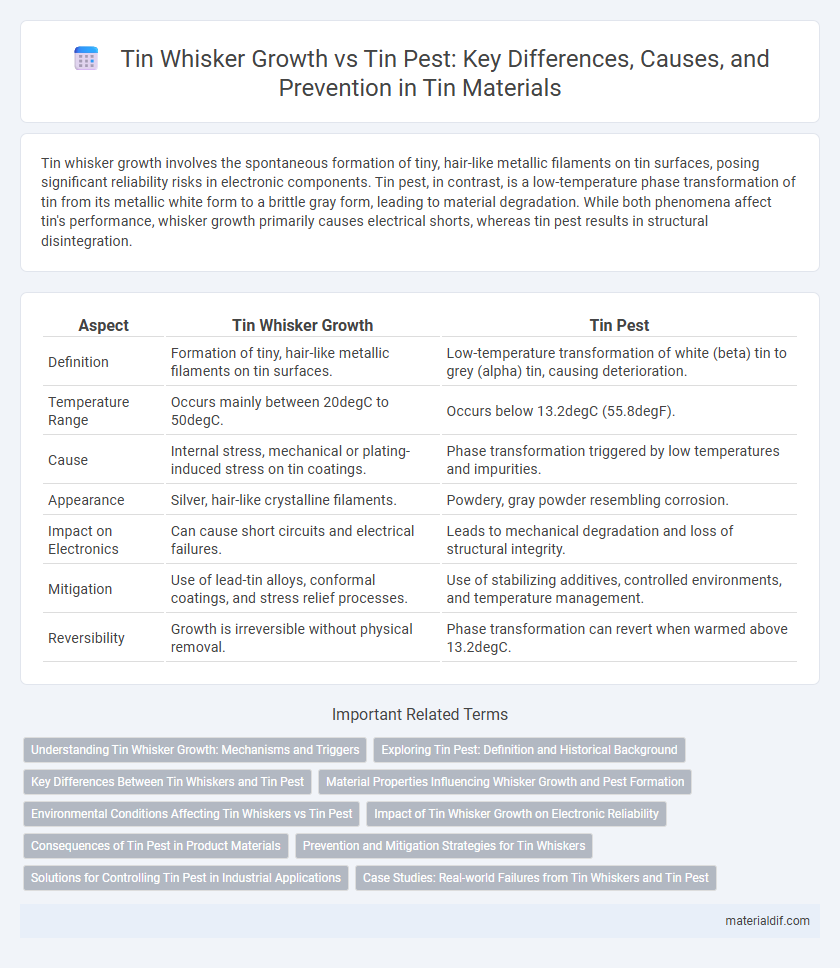

Tin whisker growth involves the spontaneous formation of tiny, hair-like metallic filaments on tin surfaces, posing significant reliability risks in electronic components. Tin pest, in contrast, is a low-temperature phase transformation of tin from its metallic white form to a brittle gray form, leading to material degradation. While both phenomena affect tin's performance, whisker growth primarily causes electrical shorts, whereas tin pest results in structural disintegration.

Table of Comparison

| Aspect | Tin Whisker Growth | Tin Pest |

|---|---|---|

| Definition | Formation of tiny, hair-like metallic filaments on tin surfaces. | Low-temperature transformation of white (beta) tin to grey (alpha) tin, causing deterioration. |

| Temperature Range | Occurs mainly between 20degC to 50degC. | Occurs below 13.2degC (55.8degF). |

| Cause | Internal stress, mechanical or plating-induced stress on tin coatings. | Phase transformation triggered by low temperatures and impurities. |

| Appearance | Silver, hair-like crystalline filaments. | Powdery, gray powder resembling corrosion. |

| Impact on Electronics | Can cause short circuits and electrical failures. | Leads to mechanical degradation and loss of structural integrity. |

| Mitigation | Use of lead-tin alloys, conformal coatings, and stress relief processes. | Use of stabilizing additives, controlled environments, and temperature management. |

| Reversibility | Growth is irreversible without physical removal. | Phase transformation can revert when warmed above 13.2degC. |

Understanding Tin Whisker Growth: Mechanisms and Triggers

Tin whisker growth occurs due to compressive stress in electroplated tin layers, causing filament-like crystalline structures to form and potentially leading to short circuits in electronic components. Key mechanisms include stress relaxation, grain boundary diffusion, and atomic migration accelerated by environmental factors such as temperature fluctuations and mechanical strain. Understanding triggers like residual stress from manufacturing processes, intermetallic compound formation, and thermal cycling is essential for developing mitigation techniques and enhancing the reliability of tin-based electronic systems.

Exploring Tin Pest: Definition and Historical Background

Tin pest is a low-temperature transformation of white metallic tin (beta-tin) into a brittle, gray powdery form (alpha-tin) occurring below 13.2degC, causing material degradation and structural failures. Historically documented since the 18th century, tin pest posed significant challenges in cold climates, particularly affecting tin-plated components in early electrical and mechanical devices. Unlike tin whisker growth, which involves filament-like crystalline protrusions causing short circuits, tin pest results from a phase change that compromises the metal's integrity through brittleness and disintegration.

Key Differences Between Tin Whiskers and Tin Pest

Tin whiskers are microscopic, hair-like crystalline filaments that grow spontaneously on the surface of pure tin coatings, causing short circuits in electronic components due to their conductive nature. In contrast, tin pest is a phase transformation phenomenon where metallic tin converts to a non-metallic, brittle gray form at low temperatures, leading to structural disintegration rather than electrical failure. The key difference lies in tin whiskers causing electrical reliability issues through physical growth, while tin pest affects mechanical integrity through low-temperature phase changes.

Material Properties Influencing Whisker Growth and Pest Formation

Tin whisker growth is significantly influenced by internal compressive stresses and grain structure within the tin plating, which create pathways for these metallic filaments to form and extend. Tin pest, a low-temperature phase transformation from beta-tin to alpha-tin occurring below 13.2degC, depends on crystal lattice instability and impurity levels that affect nucleation rates. Variations in alloy composition, such as the addition of lead or bismuth, can stabilize the tin lattice, mitigating both whisker growth and pest formation by altering mechanical stress and phase transition kinetics.

Environmental Conditions Affecting Tin Whiskers vs Tin Pest

Tin whisker growth is primarily accelerated by compressive stresses and elevated humidity levels, which create ideal conditions for metallic filament formation on tin surfaces. In contrast, tin pest occurs under extreme low temperatures, typically below 13.2degC, causing a brittle transformation from white beta-tin to gray alpha-tin crystalline structure. Controlling environmental factors such as temperature, humidity, and mechanical stress is crucial to mitigating both tin whisker proliferation and tin pest deterioration.

Impact of Tin Whisker Growth on Electronic Reliability

Tin whisker growth poses a significant threat to electronic reliability by causing short circuits and signal interference in devices with pure or nearly pure tin finishes. These microscopic, hair-like crystalline structures can bridge closely spaced conductors, leading to intermittent failures or permanent damage in aerospace, automotive, and medical electronics. Mitigation strategies such as conformal coatings and alloying with metals like lead or bismuth are critical to minimizing the risk of whisker-induced malfunctions and ensuring long-term device stability.

Consequences of Tin Pest in Product Materials

Tin pest causes structural degradation in product materials by transforming ductile white tin into brittle gray tin at low temperatures, resulting in cracks and mechanical failure. This phase change reduces electrical conductivity and connectivity in electronic components, leading to increased resistance and potential circuit malfunction. The contamination from tin pest can accelerate material embrittlement, shortening the lifespan of critical semiconductor devices and cold-temperature applications.

Prevention and Mitigation Strategies for Tin Whiskers

Tin whisker growth poses reliability risks in electronic components, necessitating prevention strategies such as applying conformal coatings and using whisker-resistant alloys like tin-silver or tin-copper. Implementing annealing processes and maintaining controlled environmental conditions, particularly humidity and temperature, further mitigates whisker formation. Regular inspection and use of physical barriers also contribute to effective management of tin whisker-related failures.

Solutions for Controlling Tin Pest in Industrial Applications

Controlling tin pest in industrial applications involves maintaining operating temperatures above 13.2degC, the threshold below which tin undergoes a phase transformation from metallic white beta-tin to brittle gray alpha-tin. Alloying tin with elements such as antimony, bismuth, or lead stabilizes the beta phase and effectively suppresses the formation of tin pest. Implementing strict environmental controls and selecting appropriate tin-based alloys ensure long-term reliability in electronic components and other industrial uses prone to low-temperature exposure.

Case Studies: Real-world Failures from Tin Whiskers and Tin Pest

Case studies reveal that tin whisker growth has caused significant failures in aerospace and electronics industries, where microscopic tin filaments short-circuited critical circuits, leading to costly malfunctions and safety hazards. In contrast, tin pest, a low-temperature transformation of metallic tin into brittle gray tin, resulted in structural degradation and mechanical failures in historical applications, such as lead-free solders and cryogenic equipment. These real-world failure analyses emphasize the necessity for mitigation strategies like alloying with lead or using conformal coatings to prevent tin whiskers and selecting appropriate tin-based materials resistant to tin pest.

Tin whisker growth vs Tin pest Infographic

materialdif.com

materialdif.com