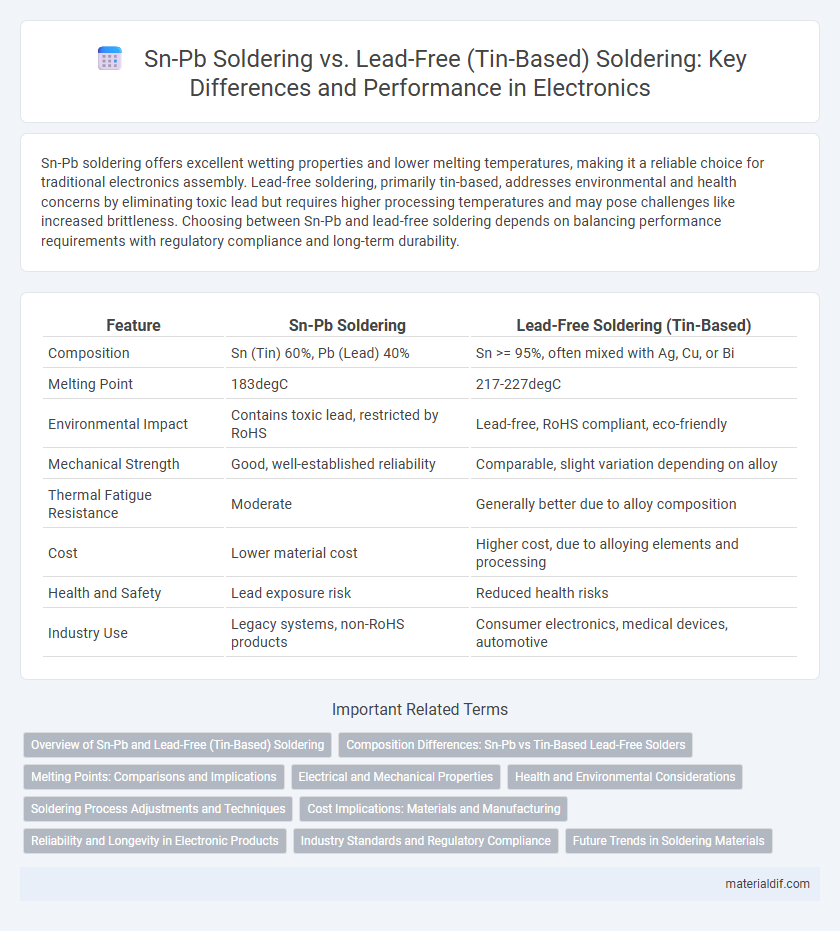

Sn-Pb soldering offers excellent wetting properties and lower melting temperatures, making it a reliable choice for traditional electronics assembly. Lead-free soldering, primarily tin-based, addresses environmental and health concerns by eliminating toxic lead but requires higher processing temperatures and may pose challenges like increased brittleness. Choosing between Sn-Pb and lead-free soldering depends on balancing performance requirements with regulatory compliance and long-term durability.

Table of Comparison

| Feature | Sn-Pb Soldering | Lead-Free Soldering (Tin-Based) |

|---|---|---|

| Composition | Sn (Tin) 60%, Pb (Lead) 40% | Sn >= 95%, often mixed with Ag, Cu, or Bi |

| Melting Point | 183degC | 217-227degC |

| Environmental Impact | Contains toxic lead, restricted by RoHS | Lead-free, RoHS compliant, eco-friendly |

| Mechanical Strength | Good, well-established reliability | Comparable, slight variation depending on alloy |

| Thermal Fatigue Resistance | Moderate | Generally better due to alloy composition |

| Cost | Lower material cost | Higher cost, due to alloying elements and processing |

| Health and Safety | Lead exposure risk | Reduced health risks |

| Industry Use | Legacy systems, non-RoHS products | Consumer electronics, medical devices, automotive |

Overview of Sn-Pb and Lead-Free (Tin-Based) Soldering

Sn-Pb soldering, composed primarily of 63% tin and 37% lead, offers excellent wetting properties and a low melting point around 183degC, making it a reliable choice for traditional electronics assembly. Lead-free soldering, often based on tin-copper, tin-silver-copper (SAC) alloys, typically melts between 217-221degC and addresses environmental and health concerns by eliminating lead content. Both soldering types utilize tin as a primary component, but lead-free alternatives require higher processing temperatures and can present different mechanical and thermal characteristics in electronics manufacturing.

Composition Differences: Sn-Pb vs Tin-Based Lead-Free Solders

Sn-Pb solder typically consists of approximately 60% tin and 40% lead, offering low melting points and excellent wetting properties ideal for traditional electronics. In contrast, tin-based lead-free solders use alloys such as Sn-Ag-Cu (SAC) containing roughly 96.5% tin, 3% silver, and 0.5% copper, providing improved environmental safety and higher melting temperatures around 217degC. The shift towards lead-free compositions addresses toxicological concerns while posing challenges in compatibility and process adjustments due to differing thermal and mechanical characteristics.

Melting Points: Comparisons and Implications

Sn-Pb solder alloys typically have melting points around 183degC, which allows for lower processing temperatures and reduced thermal stress on components. Lead-free soldering, primarily using tin-based alloys like Sn-Ag-Cu, generally requires higher melting points ranging from 217degC to 227degC, impacting circuit board materials and component reliability. The increased melting point in lead-free solders necessitates adjustments in manufacturing processes to prevent thermal damage and ensure robust joint formation.

Electrical and Mechanical Properties

Sn-Pb soldering exhibits superior electrical conductivity and lower melting points compared to lead-free, tin-based alternatives, enhancing circuit performance and ease of reflow. Lead-free solder, predominantly composed of tin with silver and copper, offers improved mechanical strength and greater resistance to thermal fatigue, increasing joint reliability in high-temperature environments. While Sn-Pb solder provides optimal electrical properties, lead-free formulations emphasize environmental compliance and mechanical durability without significantly compromising conductivity.

Health and Environmental Considerations

Sn-Pb soldering, containing approximately 60% tin and 40% lead, poses significant health risks due to lead's toxicity, including neurological damage and environmental contamination. Lead-free soldering, primarily using tin with silver and copper, reduces these hazards by eliminating lead exposure, thus being safer for workers and reducing soil and water pollution. Regulatory measures like RoHS restrict lead-based solders to promote sustainable electronics manufacturing and protect both human health and ecosystems.

Soldering Process Adjustments and Techniques

Sn-Pb soldering requires lower melting temperatures around 183degC, enabling faster wetting times and simpler temperature profiles, while lead-free tin-based soldering often demands higher reflow temperatures near 217-220degC, necessitating thermal process adjustments to prevent component damage. Techniques for lead-free soldering emphasize precise temperature ramp rates, longer soak times, and improved flux formulations to ensure proper wetting and joint reliability despite tin-silver-copper alloy characteristics. Process modifications also include extended preheating phases and controlled cooling rates to mitigate issues like tombstoning and ensure metallurgical integrity in lead-free assemblies.

Cost Implications: Materials and Manufacturing

Sn-Pb soldering generally incurs lower material costs due to the widespread availability and lower price of lead-rich alloys compared to lead-free alternatives, which often require higher-purity, more expensive tin-based formulations with silver or copper additives. Manufacturing expenses tend to be higher for lead-free soldering because of increased process temperatures and stricter quality control measures to prevent defects like tin whiskers or brittleness. These factors collectively drive up production costs in lead-free soldering despite regulatory incentives encouraging a transition away from Sn-Pb compositions.

Reliability and Longevity in Electronic Products

Sn-Pb soldering offers superior reliability and longevity in electronic products due to its lower melting point and better mechanical strength, reducing thermal stress and joint fatigue. Lead-free soldering, primarily tin-based alloys, faces challenges such as increased susceptibility to tin whiskers and higher melting temperatures, which can compromise joint durability over time. Advances in lead-free formulations and process controls continue to improve reliability, but Sn-Pb solder remains the benchmark for long-lasting electronic connections in critical applications.

Industry Standards and Regulatory Compliance

Sn-Pb soldering, traditionally favored for its low melting point and excellent wetting properties, faces stringent restrictions under RoHS and REACH regulations due to lead's toxicity and environmental impact. Lead-free soldering, primarily based on tin alloys such as Sn-Ag-Cu, aligns with modern industry standards requiring compliance with lead-free directives in electronics manufacturing. Regulatory bodies globally mandate lead-free materials to enhance product safety and environmental sustainability, making tin-based lead-free soldering essential for certified electronic component production.

Future Trends in Soldering Materials

Sn-Pb soldering, historically favored for its low melting point and excellent wetting properties, faces restrictions due to health and environmental concerns, prompting the rise of lead-free soldering primarily based on tin alloys. Future trends in soldering materials emphasize the development of high-reliability tin-based lead-free solders doped with elements like silver, copper, and bismuth to enhance mechanical strength and thermal fatigue resistance. Emerging research explores nano-engineered tin-based solders incorporating silver nanoparticles and novel flux formulations to improve joint integrity in advanced electronic packaging and meet stringent RoHS regulations.

Sn-Pb Soldering vs Lead-Free Soldering (Tin-based) Infographic

materialdif.com

materialdif.com