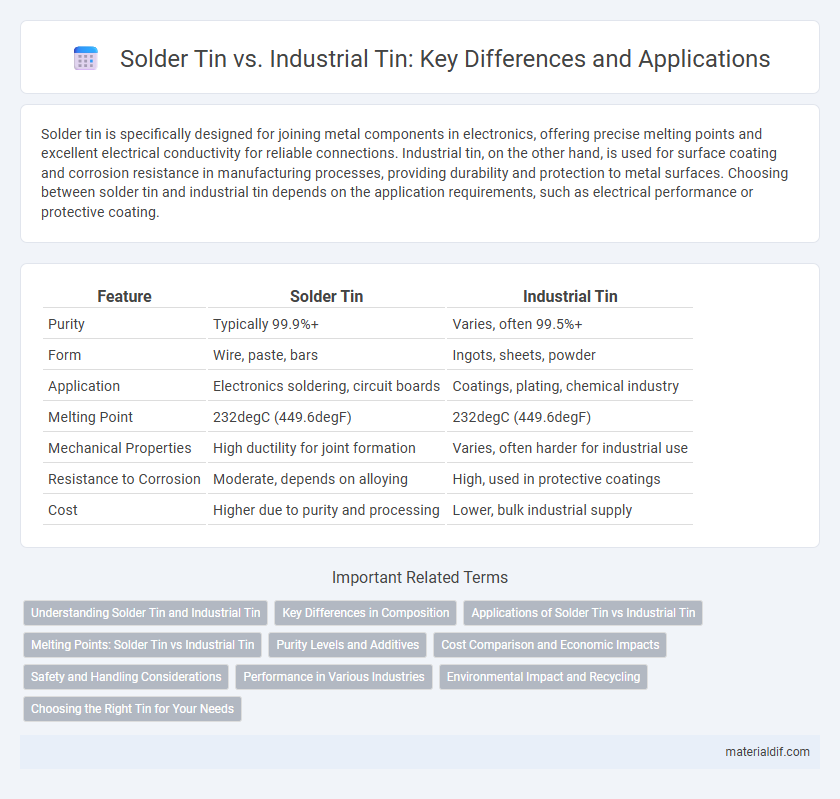

Solder tin is specifically designed for joining metal components in electronics, offering precise melting points and excellent electrical conductivity for reliable connections. Industrial tin, on the other hand, is used for surface coating and corrosion resistance in manufacturing processes, providing durability and protection to metal surfaces. Choosing between solder tin and industrial tin depends on the application requirements, such as electrical performance or protective coating.

Table of Comparison

| Feature | Solder Tin | Industrial Tin |

|---|---|---|

| Purity | Typically 99.9%+ | Varies, often 99.5%+ |

| Form | Wire, paste, bars | Ingots, sheets, powder |

| Application | Electronics soldering, circuit boards | Coatings, plating, chemical industry |

| Melting Point | 232degC (449.6degF) | 232degC (449.6degF) |

| Mechanical Properties | High ductility for joint formation | Varies, often harder for industrial use |

| Resistance to Corrosion | Moderate, depends on alloying | High, used in protective coatings |

| Cost | Higher due to purity and processing | Lower, bulk industrial supply |

Understanding Solder Tin and Industrial Tin

Solder tin primarily consists of a tin-lead or tin-silver-copper alloy designed for creating strong, conductive joints in electronic components, emphasizing low melting points and excellent electrical conductivity. Industrial tin, often used in coatings, plating, and alloy production, offers high corrosion resistance and mechanical strength, making it essential for manufacturing, chemical applications, and food packaging. Differentiating these types involves considering their specific melting points, purity levels, and intended applications in electronics versus industrial manufacturing.

Key Differences in Composition

Solder tin typically contains a higher percentage of lead or other alloying elements such as silver and copper to improve melting point and wetting properties, making it ideal for electronic applications. Industrial tin, in contrast, is often purer with minimal alloying, designed for chemical resistance, plating, and manufacturing processes where mechanical strength and corrosion resistance are critical. These compositional distinctions directly impact performance characteristics, with solder tin optimized for electrical conductivity and melting behavior, while industrial tin prioritizes durability and corrosion resistance.

Applications of Solder Tin vs Industrial Tin

Solder tin is primarily used in electronics and electrical applications for joining metal components due to its low melting point and excellent electrical conductivity. Industrial tin, in contrast, finds applications in manufacturing processes such as plating, alloys, and chemical catalysts where higher durability and corrosion resistance are required. The choice between solder tin and industrial tin depends on specific performance requirements in electronics assembly versus heavy-duty industrial uses.

Melting Points: Solder Tin vs Industrial Tin

Solder tin typically melts at a lower temperature range of around 183 to 190degC, primarily due to its alloy composition with metals like lead or silver, ensuring efficient bonding during electronic assembly. Industrial tin, being more pure, possesses a higher melting point close to 232degC, making it suitable for applications requiring greater thermal stability and strength. This distinct difference in melting points dictates their specific uses in manufacturing and electronics industries.

Purity Levels and Additives

Solder tin typically has a purity level of 99.3% to 99.9%, often combined with additives like silver, copper, or flux to enhance melting properties and joint strength. Industrial tin generally boasts higher purity, exceeding 99.9%, with minimal or no additives, optimizing it for applications requiring maximum corrosion resistance and electrical conductivity. The choice between solder tin and industrial tin depends on the specific purity requirements and the chemical composition tailored for electronic assembly versus industrial manufacturing.

Cost Comparison and Economic Impacts

Solder tin generally costs more per kilogram than industrial tin due to its higher purity requirements and specialized alloy compositions, which directly affects manufacturing expenses in electronics industries. Industrial tin, used in applications such as coatings, plating, and tin-based chemicals, benefits from lower processing costs and larger-scale production, making it more economical for bulk industrial use. The economic impact reveals that while solder tin drives cost efficiency in precision electronics, industrial tin supports broader material affordability and supply stability across manufacturing sectors.

Safety and Handling Considerations

Solder tin typically contains alloys such as tin-lead or tin-silver-copper, requiring careful handling to avoid lead exposure and ensure proper ventilation due to fumes released during soldering. Industrial tin, often used in coatings and plating, demands precautions against inhalation of tin dust and prolonged skin contact to prevent potential respiratory and dermatological issues. Both forms necessitate adherence to safety data sheets and use of personal protective equipment to minimize health risks in manufacturing environments.

Performance in Various Industries

Solder tin exhibits excellent thermal and electrical conductivity, making it ideal for electronics manufacturing where precise, reliable connections are critical. Industrial tin, valued for its corrosion resistance and malleability, is widely used in plating, packaging, and chemical processing industries to enhance product durability. The distinct performance attributes of solder tin and industrial tin dictate their specialized applications across sectors such as automotive, aerospace, and consumer electronics.

Environmental Impact and Recycling

Solder tin, primarily used in electronics, often contains lead-free alloys designed to minimize environmental toxicity and facilitate recycling processes, reducing hazardous waste in electronic scrap. Industrial tin, applied in coatings and plating, poses challenges due to its potential for heavy metal contamination and slower recycling rates, necessitating improved recovery technologies to mitigate environmental impact. Enhanced recycling systems for both solder and industrial tin contribute to resource conservation and decreased ecological footprint through metal recovery and reuse.

Choosing the Right Tin for Your Needs

Solder tin, characterized by its low melting point and excellent electrical conductivity, is ideal for electronics and delicate component connections, whereas industrial tin offers higher purity and strength suitable for manufacturing, plating, and corrosion-resistant coatings. Evaluating the specific application requirements, such as thermal tolerance, mechanical stress, and environmental exposure, ensures optimal tin selection that maximizes performance and durability. Selecting the right tin grade directly impacts product reliability, manufacturing efficiency, and overall cost-effectiveness in various industrial and technological applications.

Solder tin vs Industrial tin Infographic

materialdif.com

materialdif.com