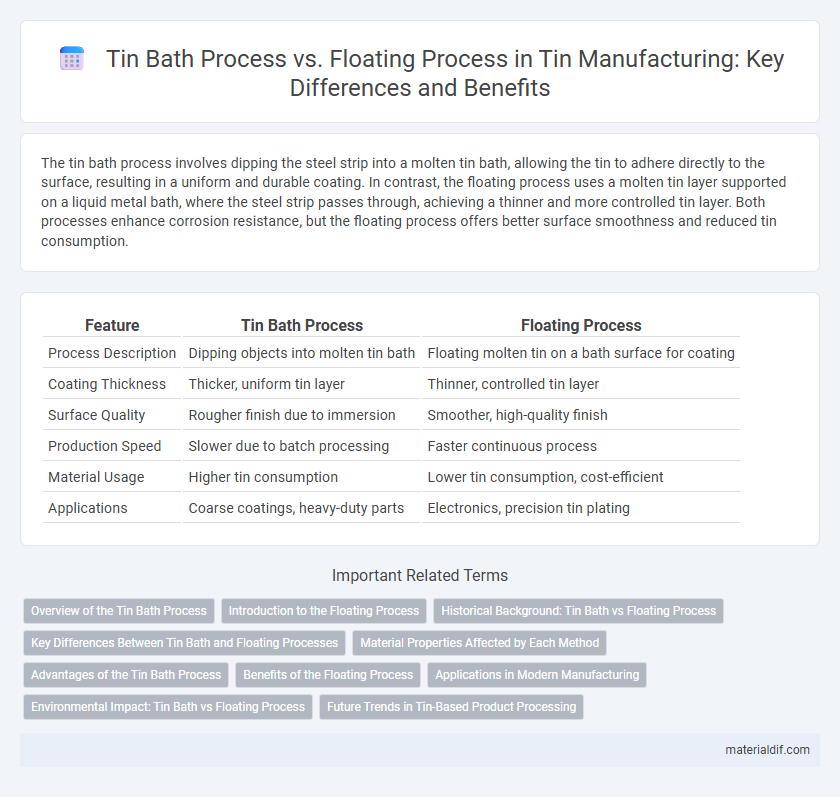

The tin bath process involves dipping the steel strip into a molten tin bath, allowing the tin to adhere directly to the surface, resulting in a uniform and durable coating. In contrast, the floating process uses a molten tin layer supported on a liquid metal bath, where the steel strip passes through, achieving a thinner and more controlled tin layer. Both processes enhance corrosion resistance, but the floating process offers better surface smoothness and reduced tin consumption.

Table of Comparison

| Feature | Tin Bath Process | Floating Process |

|---|---|---|

| Process Description | Dipping objects into molten tin bath | Floating molten tin on a bath surface for coating |

| Coating Thickness | Thicker, uniform tin layer | Thinner, controlled tin layer |

| Surface Quality | Rougher finish due to immersion | Smoother, high-quality finish |

| Production Speed | Slower due to batch processing | Faster continuous process |

| Material Usage | Higher tin consumption | Lower tin consumption, cost-efficient |

| Applications | Coarse coatings, heavy-duty parts | Electronics, precision tin plating |

Overview of the Tin Bath Process

The Tin Bath Process involves immersing steel sheets into a molten tin bath, allowing for uniform coating and excellent adhesion crucial for corrosion resistance in cans and packaging. This method ensures precise control over coating thickness, typically ranging from 1 to 10 microns, enhancing the material's durability and solderability. Unlike the Floating Process, the Tin Bath Process provides a more consistent tin layer, making it ideal for high-quality tinplate production.

Introduction to the Floating Process

The floating process, also known as the electrolytic tinning method, offers a precise alternative to the traditional tin bath process by depositing tin on metal strips through electrochemical reactions, ensuring a uniform and controlled coating. Unlike the conventional tin bath, which relies on molten tin immersion, the floating process enables higher purity and improved adhesion, making it ideal for producing tinplate used in food packaging and electronics. This method significantly reduces tin consumption and environmental impact due to its efficient use of tin and lower energy requirements.

Historical Background: Tin Bath vs Floating Process

The tin bath process, historically dominant in steel galvanization, involves immersing steel sheets in molten tin to form a protective coating that enhances corrosion resistance. Emerging in the early 20th century, the floating process was developed to provide a more uniform tin layer by allowing steel strips to pass over a molten tin bath without direct immersion, improving surface quality. Both methods reflect industrial advancements in tin coating technology, with the tin bath process emphasizing simplicity and the floating process focusing on precision and efficiency.

Key Differences Between Tin Bath and Floating Processes

The tin bath process involves immersing steel in molten tin to achieve a uniform coating, resulting in strong adhesion and enhanced corrosion resistance. In contrast, the floating process floats the steel strip over a molten tin bath without full immersion, allowing for a thinner and more controlled tin layer ideal for applications requiring precise coating thickness. Key differences include coating thickness control, adhesion strength, and process efficiency, with the tin bath process offering more robust protection and the floating process excelling in material conservation and surface finish quality.

Material Properties Affected by Each Method

The Tin bath process enhances surface uniformity and corrosion resistance by allowing better wetting and adhesion of the tin layer, resulting in improved mechanical strength and electrical conductivity. The Floating process, alternatively, offers superior thickness control and smoother coatings due to the continuous contact with molten tin, which minimizes surface defects and reduces internal stresses. Differences in grain structure and crystallinity between the two methods impact durability and thermal stability, favoring specific tin-coated applications depending on performance requirements.

Advantages of the Tin Bath Process

The Tin Bath Process offers superior control over coating thickness and uniformity compared to the Floating Process, resulting in higher quality finishes for tin plating applications. This method reduces oxidation and contamination risks by immersing substrates directly in molten tin, enhancing adhesion and corrosion resistance. Furthermore, the Tin Bath Process allows for greater versatility in handling various substrate sizes and shapes, optimizing production efficiency in industrial settings.

Benefits of the Floating Process

The Floating process offers superior surface uniformity and higher plating efficiency compared to the Tin bath process, reducing defects such as uneven coating and thinning. It enables precise control over tin thickness, enhancing the durability and corrosion resistance of electronic components. This method also minimizes environmental impact by lowering chemical usage and waste generation.

Applications in Modern Manufacturing

The tin bath process excels in applying tin coatings on steel strips for corrosion resistance in automotive and electronics industries, offering precise control over coating thickness and uniformity. The floating process is widely used for producing high-quality, flat tin surfaces on thin steel sheets, important in packaging and food industry applications. Modern manufacturing prioritizes the tin bath process for complex geometries, while the floating process supports large-scale flat sheet production with consistent surface finish.

Environmental Impact: Tin Bath vs Floating Process

The Tin Bath process generates higher levels of wastewater containing heavy metals and acids, leading to more environmental contamination risks compared to the Floating process. The Floating process uses a closed-loop system that recycles tin electrolytes, significantly reducing metal discharge and minimizing hazardous waste generation. Overall, the Floating process demonstrates a lower environmental footprint due to better resource efficiency and reduced pollutant emissions.

Future Trends in Tin-Based Product Processing

Future trends in tin-based product processing emphasize advancements in the Floating process due to its superior surface smoothness and reduced mechanical stress compared to the Tin bath process. Innovations in controlled atmosphere and temperature regulation during the Floating process enhance coating uniformity and adherence, meeting the growing demand for high-performance electronic components. Research also targets eco-friendly and energy-efficient Floating techniques to align with sustainable manufacturing goals in the tin industry.

Tin bath process vs Floating process Infographic

materialdif.com

materialdif.com