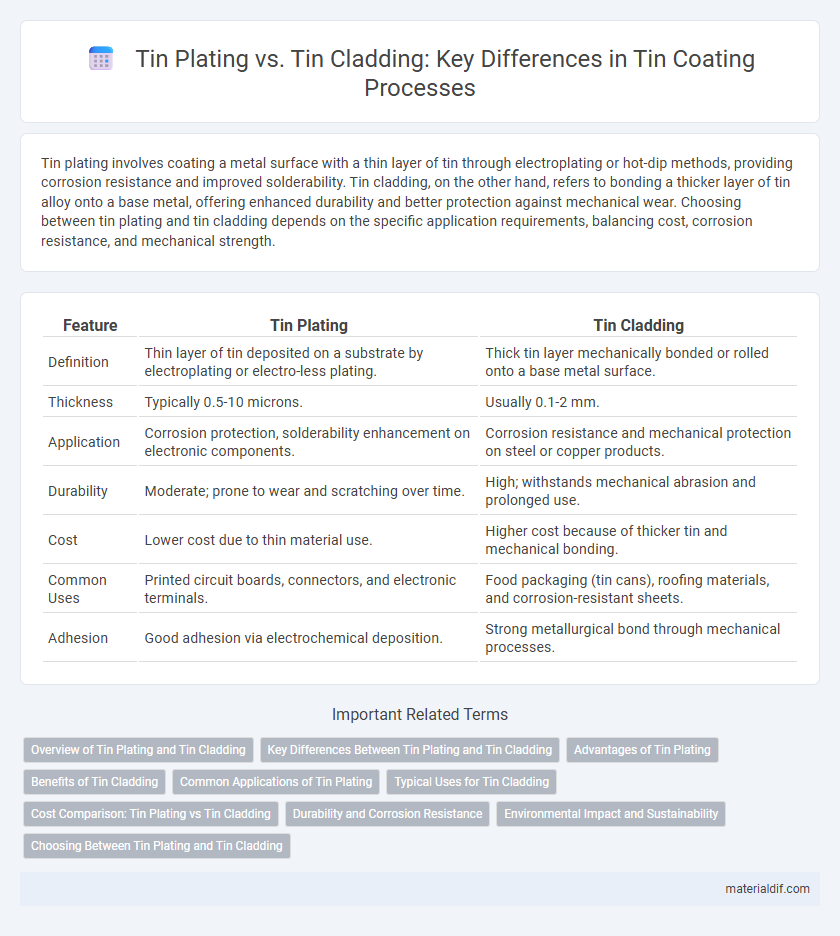

Tin plating involves coating a metal surface with a thin layer of tin through electroplating or hot-dip methods, providing corrosion resistance and improved solderability. Tin cladding, on the other hand, refers to bonding a thicker layer of tin alloy onto a base metal, offering enhanced durability and better protection against mechanical wear. Choosing between tin plating and tin cladding depends on the specific application requirements, balancing cost, corrosion resistance, and mechanical strength.

Table of Comparison

| Feature | Tin Plating | Tin Cladding |

|---|---|---|

| Definition | Thin layer of tin deposited on a substrate by electroplating or electro-less plating. | Thick tin layer mechanically bonded or rolled onto a base metal surface. |

| Thickness | Typically 0.5-10 microns. | Usually 0.1-2 mm. |

| Application | Corrosion protection, solderability enhancement on electronic components. | Corrosion resistance and mechanical protection on steel or copper products. |

| Durability | Moderate; prone to wear and scratching over time. | High; withstands mechanical abrasion and prolonged use. |

| Cost | Lower cost due to thin material use. | Higher cost because of thicker tin and mechanical bonding. |

| Common Uses | Printed circuit boards, connectors, and electronic terminals. | Food packaging (tin cans), roofing materials, and corrosion-resistant sheets. |

| Adhesion | Good adhesion via electrochemical deposition. | Strong metallurgical bond through mechanical processes. |

Overview of Tin Plating and Tin Cladding

Tin plating involves applying a thin layer of tin onto the surface of a metal substrate through electroplating or hot-dip methods, enhancing corrosion resistance and solderability. Tin cladding consists of bonding a thicker tin layer onto a base metal, typically through rolling or extrusion, which provides improved mechanical protection and longevity. Both processes utilize tin's excellent conductivity and anti-corrosive properties but differ primarily in coating thickness and application techniques.

Key Differences Between Tin Plating and Tin Cladding

Tin plating involves electroplating a thin layer of tin onto a base metal surface, providing corrosion resistance and improved solderability, typically measured in microns. Tin cladding consists of mechanically bonding a thicker sheet of tin onto a substrate metal, offering enhanced durability and protection against wear and corrosion for industrial applications. The key differences lie in thickness, bonding methods, and resulting mechanical strength, with plating providing a thinner, uniform coating and cladding delivering a heavier, more robust layer.

Advantages of Tin Plating

Tin plating offers superior corrosion resistance by creating a uniform and thin protective layer on metal surfaces, effectively preventing oxidation and rust. The plating process enhances solderability, making it ideal for electronic components and wiring applications where reliable electrical connections are essential. Additionally, tin plating provides excellent surface smoothness and adhesion, improving durability and aesthetic appeal without significantly increasing manufacturing costs.

Benefits of Tin Cladding

Tin cladding provides a thicker, more durable layer of corrosion resistance compared to tin plating, making it ideal for protecting steel surfaces in harsh environments. The metallurgical bond in tin cladding ensures superior adhesion and enhanced mechanical strength, which extends the lifespan of components in automotive and food processing industries. This robust coating also offers excellent conductivity and solderability, improving performance in electrical applications.

Common Applications of Tin Plating

Tin plating is widely used for corrosion resistance and solderability in electrical connectors, food packaging, and automotive components due to its thin, uniform layer that preserves base metal properties. Common applications include printed circuit boards, steel cans, and fasteners, where tin plating provides a smooth, conductive, and protective surface. Unlike tin cladding, which involves a thicker tin layer for structural strength, tin plating excels in lightweight coating needs crucial for electronics and packaging industries.

Typical Uses for Tin Cladding

Tin cladding is typically used in electronic components and food packaging due to its excellent corrosion resistance and non-toxic properties, providing a durable protective layer over base metals like steel or copper. It offers superior weldability and solderability, making it ideal for automotive parts and electrical connectors where reliable conductivity and protection from oxidation are essential. Unlike tin plating, tin cladding involves a thicker application, resulting in enhanced mechanical strength and longer-lasting performance in harsh environments.

Cost Comparison: Tin Plating vs Tin Cladding

Tin plating typically incurs lower upfront costs compared to tin cladding due to thinner metal usage and simpler application processes. Tin cladding involves bonding a thicker layer of tin to a base metal, raising material and fabrication expenses but offering enhanced durability and corrosion resistance. Cost-effectiveness depends on the required application, with tin plating favored for economical, thin coatings and tin cladding preferred for long-term performance despite higher initial investment.

Durability and Corrosion Resistance

Tin plating provides a thin, uniform layer of tin that enhances corrosion resistance on metal substrates, making it suitable for delicate electronic components and applications requiring precise coating thickness. Tin cladding involves bonding a thicker tin layer through mechanical or metallurgical processes, offering superior durability and enhanced protection against abrasion and corrosion in harsh environments. The choice between tin plating and tin cladding depends on the required balance of corrosion resistance, mechanical strength, and application-specific durability needs.

Environmental Impact and Sustainability

Tin plating involves coating steel or copper substrates with a thin layer of tin to provide corrosion resistance and food safety, resulting in minimal environmental impact due to low material usage and recyclability. Tin cladding, which applies a thicker tin layer or tin alloy, offers enhanced durability but uses more resources and energy, potentially increasing carbon footprint and waste generation. Sustainable practices in both processes prioritize efficient material use, recycling of scrap metals, and reduction of harmful chemicals to mitigate environmental effects.

Choosing Between Tin Plating and Tin Cladding

Choosing between tin plating and tin cladding depends on the specific application requirements, including corrosion resistance, conductivity, and cost. Tin plating offers a thin, uniform coating ideal for solderability and protecting electronic components, while tin cladding provides a thicker, more durable layer suitable for heavy-duty industrial uses. Consider factors such as mechanical wear, exposure conditions, and desired lifespan to determine the most effective surface treatment.

Tin Plating vs Tin Cladding Infographic

materialdif.com

materialdif.com