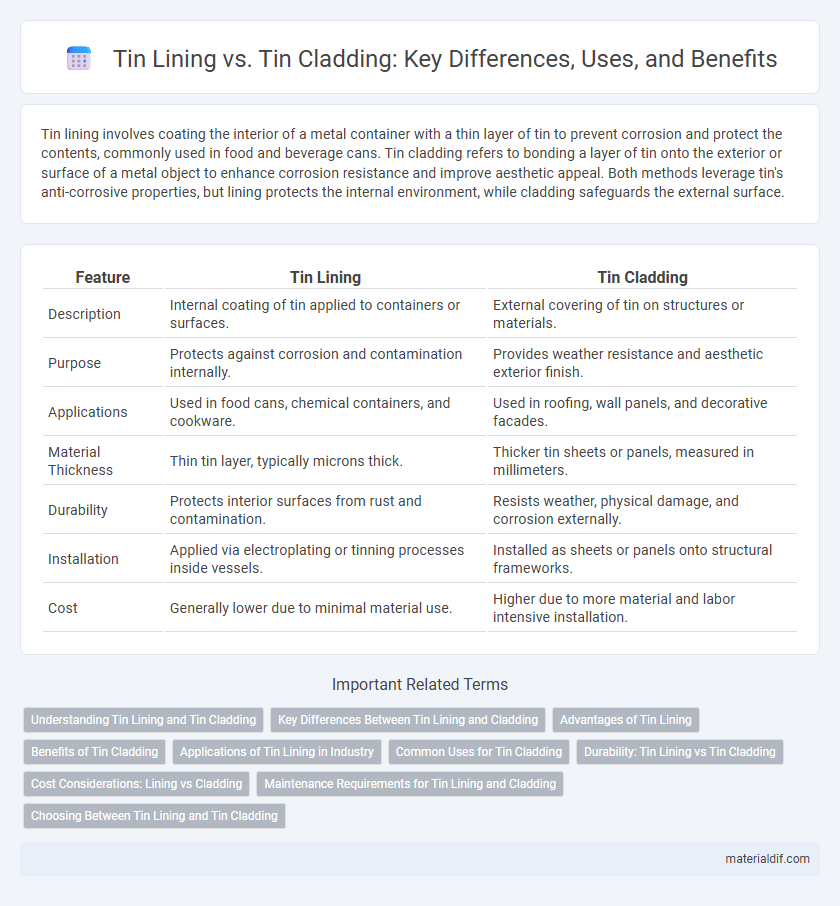

Tin lining involves coating the interior of a metal container with a thin layer of tin to prevent corrosion and protect the contents, commonly used in food and beverage cans. Tin cladding refers to bonding a layer of tin onto the exterior or surface of a metal object to enhance corrosion resistance and improve aesthetic appeal. Both methods leverage tin's anti-corrosive properties, but lining protects the internal environment, while cladding safeguards the external surface.

Table of Comparison

| Feature | Tin Lining | Tin Cladding |

|---|---|---|

| Description | Internal coating of tin applied to containers or surfaces. | External covering of tin on structures or materials. |

| Purpose | Protects against corrosion and contamination internally. | Provides weather resistance and aesthetic exterior finish. |

| Applications | Used in food cans, chemical containers, and cookware. | Used in roofing, wall panels, and decorative facades. |

| Material Thickness | Thin tin layer, typically microns thick. | Thicker tin sheets or panels, measured in millimeters. |

| Durability | Protects interior surfaces from rust and contamination. | Resists weather, physical damage, and corrosion externally. |

| Installation | Applied via electroplating or tinning processes inside vessels. | Installed as sheets or panels onto structural frameworks. |

| Cost | Generally lower due to minimal material use. | Higher due to more material and labor intensive installation. |

Understanding Tin Lining and Tin Cladding

Tin lining involves applying a thin layer of pure tin directly onto the surface of metal containers or equipment to provide corrosion resistance and prevent contamination, commonly used in food and chemical industries. Tin cladding, on the other hand, refers to bonding a thicker layer of tin alloy onto a base metal substrate, offering enhanced durability and mechanical strength for industrial applications. Understanding the differences between tin lining and tin cladding is crucial for selecting appropriate materials in manufacturing processes where corrosion protection and metal compatibility are critical.

Key Differences Between Tin Lining and Cladding

Tin lining involves coating the interior surfaces of metal containers with a thin layer of pure tin to prevent corrosion and contamination, commonly used in food and beverage industries. Tin cladding refers to bonding a layer of tin onto the exterior of another metal, enhancing corrosion resistance and aesthetic appeal, often applied in architectural or decorative settings. The key difference lies in their application focus--lining protects internal surfaces for food safety, while cladding reinforces outer surfaces for durability and appearance.

Advantages of Tin Lining

Tin lining offers superior corrosion resistance by providing a seamless, protective barrier against moisture and acidic substances, extending the lifespan of containers and equipment. It ensures food-grade safety, preventing contamination and preserving the purity and taste of consumables. Enhanced durability and ease of cleaning make tin lining a cost-effective choice for industries requiring stringent hygiene standards, such as food processing and pharmaceuticals.

Benefits of Tin Cladding

Tin cladding provides enhanced corrosion resistance, extending the lifespan of steel structures exposed to harsh environments. This method creates a robust barrier against moisture and chemical attack, improving durability compared to tin lining which is limited to internal surfaces. The exterior application of tin cladding also offers superior mechanical protection and easier maintenance, making it ideal for industrial and architectural uses.

Applications of Tin Lining in Industry

Tin lining is extensively used in the chemical and food industries for corrosion-resistant coatings inside storage tanks and pipes, ensuring product purity and extending equipment lifespan. This technique is ideal for handling acidic substances, preventing contamination, and maintaining material integrity under harsh conditions. Unlike tin cladding, which involves applying a thin tin layer on external surfaces for aesthetic or light corrosion protection, tin lining provides full internal protection critical for industrial processing environments.

Common Uses for Tin Cladding

Tin cladding is commonly used in food packaging, electrical components, and roofing due to its corrosion resistance and non-toxic properties. It offers a durable protective layer for steel and other metals, preventing rust and extending the lifespan of various industrial and household products. The versatility of tin cladding makes it ideal for applications requiring both protective and aesthetic qualities in environments exposed to moisture and chemicals.

Durability: Tin Lining vs Tin Cladding

Tin lining offers superior durability by providing a thicker, more robust protective layer that resists corrosion and extends the lifespan of containers in harsh environments. Tin cladding, while effective for surface protection, typically features a thinner coating that is more prone to wear and damage over time. The enhanced resistance of tin lining against chemical reactions and mechanical wear makes it preferable for applications requiring long-term durability.

Cost Considerations: Lining vs Cladding

Tin lining typically involves coating the interior surface of containers to prevent corrosion, offering a cost-effective solution for food and beverage packaging due to lower material usage. Tin cladding, which bonds a thicker tin layer to the exterior or entire surface of metal substrates, incurs higher manufacturing expenses but provides enhanced durability and resistance to environmental factors. When evaluating cost considerations, tin lining is generally more economical for applications requiring corrosion resistance without heavy external protection, while tin cladding suits industrial uses demanding greater mechanical strength and longevity.

Maintenance Requirements for Tin Lining and Cladding

Tin lining requires regular inspection for corrosion and periodic resealing to maintain its protective barrier, especially in environments exposed to moisture or chemicals. Tin cladding demands less frequent maintenance but should be checked for physical damage and fastening integrity to prevent structural issues. Both methods benefit from cleaning to remove debris and prevent buildup that can accelerate wear.

Choosing Between Tin Lining and Tin Cladding

Choosing between tin lining and tin cladding depends on the specific application requirements, such as corrosion resistance and durability. Tin lining involves applying a thin layer of tin inside a vessel to protect contents from contamination and corrosion, ideal for food and chemical storage. Tin cladding, on the other hand, covers external surfaces with tin for enhanced protection against environmental corrosion and mechanical damage, making it suitable for structural and industrial uses.

Tin Lining vs Tin Cladding Infographic

materialdif.com

materialdif.com