Lead-free tin offers a safer alternative to leaded tin by eliminating toxic lead content, making it ideal for food packaging and children's products. It provides comparable soldering performance with improved environmental and health benefits, reducing hazardous waste and contamination risks. Industries are increasingly adopting lead-free tin to comply with regulations like RoHS, ensuring consumer safety and sustainability.

Table of Comparison

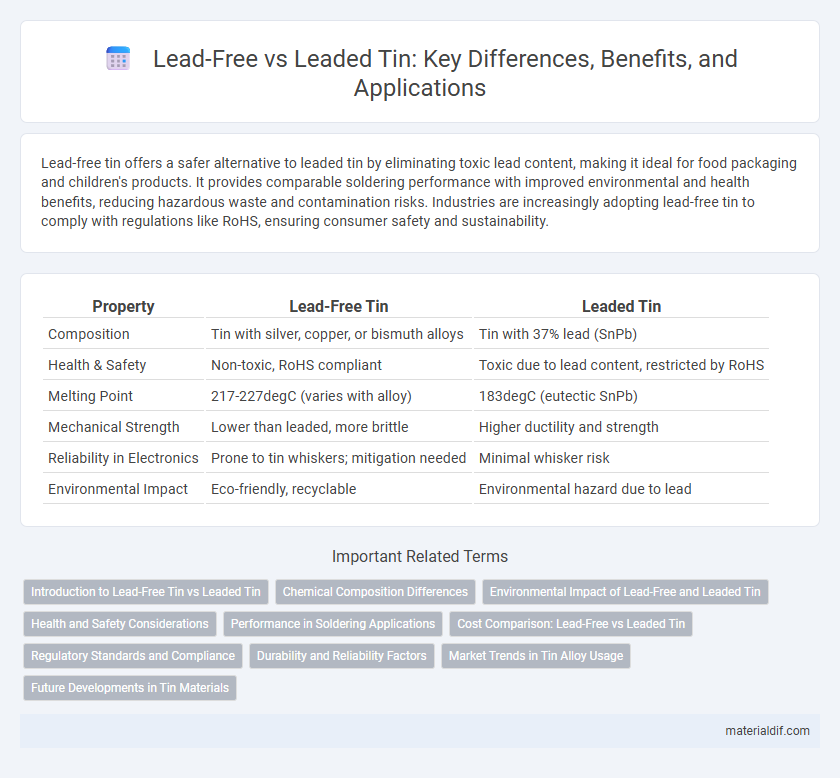

| Property | Lead-Free Tin | Leaded Tin |

|---|---|---|

| Composition | Tin with silver, copper, or bismuth alloys | Tin with 37% lead (SnPb) |

| Health & Safety | Non-toxic, RoHS compliant | Toxic due to lead content, restricted by RoHS |

| Melting Point | 217-227degC (varies with alloy) | 183degC (eutectic SnPb) |

| Mechanical Strength | Lower than leaded, more brittle | Higher ductility and strength |

| Reliability in Electronics | Prone to tin whiskers; mitigation needed | Minimal whisker risk |

| Environmental Impact | Eco-friendly, recyclable | Environmental hazard due to lead |

Introduction to Lead-Free Tin vs Leaded Tin

Lead-free tin is increasingly favored in electronics manufacturing due to stricter environmental regulations limiting lead content, promoting safer and more sustainable products. Unlike traditional leaded tin, which contains around 37% lead alloyed with tin to improve melting point and mechanical properties, lead-free alternatives use metals such as silver, copper, and bismuth to meet RoHS compliance standards. The shift towards lead-free tin reduces health risks and environmental hazards associated with lead, though it requires adjustments in soldering processes and material compatibility.

Chemical Composition Differences

Lead-free tin primarily consists of pure tin or tin alloyed with metals like silver, copper, or bismuth, eliminating the toxic lead content found in leaded tin. Leaded tin contains significant amounts of lead, typically around 40-60%, combined with tin to lower melting points and improve flow characteristics in soldering. The absence of lead in lead-free tin results in distinct physical and chemical properties, including higher melting points and increased hardness, influencing its performance in electronic and industrial applications.

Environmental Impact of Lead-Free and Leaded Tin

Lead-free tin significantly reduces environmental contamination by eliminating toxic lead emissions during manufacturing and disposal processes, thereby minimizing soil and water pollution. In contrast, leaded tin contributes to hazardous waste accumulation and poses serious health risks to ecosystems and human populations due to lead's persistent bioaccumulation. Transitioning to lead-free tin fosters sustainable electronic production and supports regulatory compliance with environmental protection standards such as RoHS.

Health and Safety Considerations

Lead-free tin reduces exposure to toxic lead, significantly lowering health risks such as lead poisoning and neurological damage during manufacturing and handling. Leaded tin, although historically preferred for its superior soldering properties, poses serious health hazards, including harmful effects on the nervous system and developmental issues, especially in vulnerable populations. Strict regulations and safety standards promote the use of lead-free tin to ensure safer workplaces and environmental protection while maintaining material performance.

Performance in Soldering Applications

Lead-free tin alloys typically exhibit higher melting points and increased thermal fatigue resistance compared to leaded tin, enhancing durability in soldering applications. Leaded tin solder offers superior wetting ability and lower melting temperature, facilitating easier solder joint formation and improved flow characteristics. Performance in soldering is influenced by the specific alloy composition, with lead-free options favored for environmental compliance while leaded tin remains preferred for certain high-reliability electronic assemblies.

Cost Comparison: Lead-Free vs Leaded Tin

Lead-free tin, primarily composed of tin-copper or tin-silver alloys, generally incurs higher material costs compared to traditional leaded tin due to the expensive metals involved and stricter environmental regulations. Leaded tin, often consisting of a tin-lead alloy with a lower melting point, offers cheaper soldering solutions but faces increasing restrictions because of lead's toxicity and disposal challenges. Cost analysis must consider not only upfront material expenses but also long-term compliance and health-related liabilities, making lead-free tin more cost-effective in regulated markets despite higher initial prices.

Regulatory Standards and Compliance

Lead-free tin complies with RoHS (Restriction of Hazardous Substances) standards, restricting the use of lead to reduce environmental and health risks in electronics manufacturing. Leaded tin, while offering superior soldering performance, often fails to meet stringent regulations like REACH and RoHS, limiting its use in consumer products. Manufacturers must balance compliance with these regulatory standards to ensure product safety and market access in regions enforcing hazardous substance restrictions.

Durability and Reliability Factors

Lead-free tin alloys exhibit enhanced corrosion resistance and improved thermal stability compared to leaded tin, resulting in greater long-term durability for electronic components. Leaded tin, while historically valued for its ease of soldering and mechanical strength, tends to suffer from tin whisker formation, which can compromise reliability in sensitive electronics. Industry standards increasingly favor lead-free tin due to its superior environmental compliance and consistent performance under thermal cycling and mechanical stress.

Market Trends in Tin Alloy Usage

Lead-free tin alloys have seen significant growth in market demand due to global regulations such as RoHS restricting lead content in electronic components, driving manufacturers to shift towards environmentally friendly materials. The leaded tin market remains steady in specialized industrial applications where superior mechanical properties and soldering performance are critical. Emerging trends indicate a gradual increase in the adoption of lead-free tin alloys in automotive and consumer electronics sectors, supported by advancements in alloy formulations that enhance reliability and reduce environmental impact.

Future Developments in Tin Materials

Future developments in tin materials emphasize the transition from leaded tin to lead-free tin to meet global environmental regulations and consumer safety standards. Innovations in lead-free tin alloys improve solderability, thermal fatigue resistance, and reduce tin whisker growth, enhancing long-term reliability in electronics. Researchers focus on optimizing tin-based compounds to support sustainable manufacturing and performance in emerging technologies such as flexible electronics and electric vehicles.

Lead-Free Tin vs Leaded Tin Infographic

materialdif.com

materialdif.com