Tin-lead solder offers excellent electrical conductivity and ease of use due to its low melting point, making it a preferred choice in many traditional electronics applications. Lead-free solder, typically composed of tin combined with metals like silver and copper, addresses health and environmental concerns but requires higher temperatures and may pose challenges such as increased brittleness and different wetting properties. Selecting between tin-lead and lead-free solder depends on factors like regulatory compliance, joint reliability, and manufacturing processes in the electronics industry.

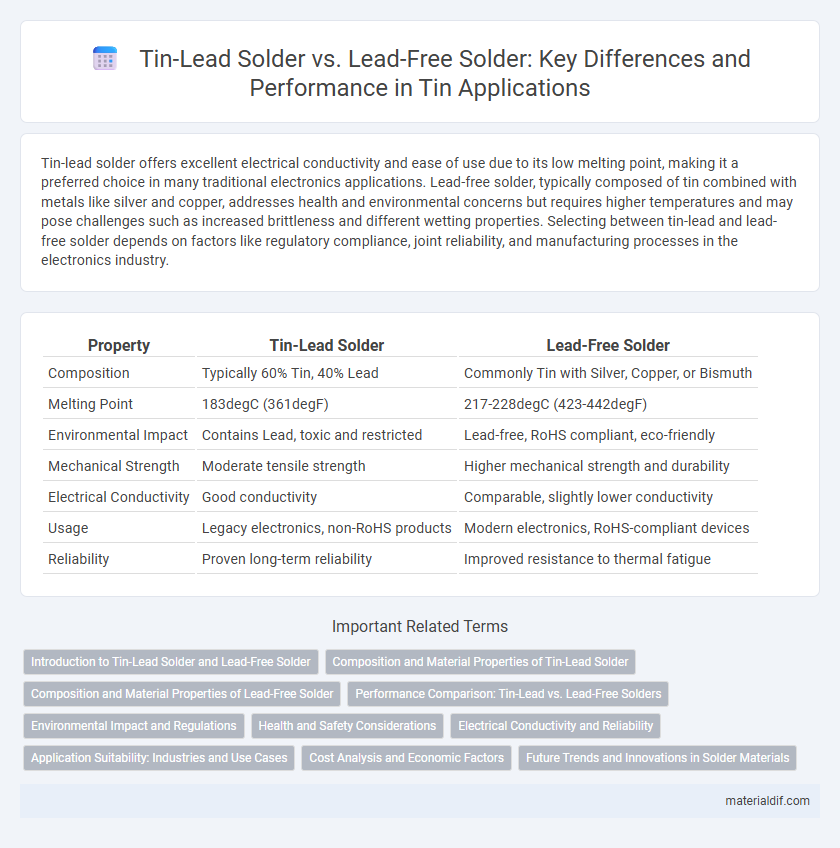

Table of Comparison

| Property | Tin-Lead Solder | Lead-Free Solder |

|---|---|---|

| Composition | Typically 60% Tin, 40% Lead | Commonly Tin with Silver, Copper, or Bismuth |

| Melting Point | 183degC (361degF) | 217-228degC (423-442degF) |

| Environmental Impact | Contains Lead, toxic and restricted | Lead-free, RoHS compliant, eco-friendly |

| Mechanical Strength | Moderate tensile strength | Higher mechanical strength and durability |

| Electrical Conductivity | Good conductivity | Comparable, slightly lower conductivity |

| Usage | Legacy electronics, non-RoHS products | Modern electronics, RoHS-compliant devices |

| Reliability | Proven long-term reliability | Improved resistance to thermal fatigue |

Introduction to Tin-Lead Solder and Lead-Free Solder

Tin-lead solder, traditionally composed of approximately 60% tin and 40% lead, offers excellent electrical conductivity and a low melting point around 183degC, making it a preferred choice in electronics soldering for decades. Lead-free solder, compliant with environmental regulations like RoHS, typically uses alloys such as tin-silver-copper (SAC), melting at higher temperatures near 217-220degC, and reduces health and environmental risks by eliminating lead content. The transition to lead-free solder addresses toxicity concerns while maintaining mechanical reliability in modern electronic assemblies.

Composition and Material Properties of Tin-Lead Solder

Tin-lead solder typically consists of about 60% tin and 40% lead, offering a low melting point around 183degC and excellent wettability, which ensures strong, reliable electrical connections. The lead content enhances ductility and fatigue resistance, making the alloy easier to work with during soldering processes. Despite its favorable mechanical and thermal properties, tin-lead solder poses environmental and health concerns due to lead toxicity.

Composition and Material Properties of Lead-Free Solder

Lead-free solder typically consists of a combination of tin, silver, and copper, with common formulations such as Sn96.5/Ag3.0/Cu0.5, offering improved thermal fatigue resistance and higher melting points compared to traditional tin-lead solder. The absence of lead enhances environmental compliance and reduces toxicity, while the added silver and copper increase mechanical strength and electrical conductivity. Material properties like increased hardness and reduced ductility require careful process control during soldering to prevent joint failures.

Performance Comparison: Tin-Lead vs. Lead-Free Solders

Tin-lead solder offers superior wettability and lower melting point around 183degC, enabling better flow and joint formation in traditional electronics assembly. Lead-free solders, typically based on tin-silver-copper (SAC) alloys, exhibit higher melting points near 217-220degC and improved thermal and mechanical reliability under harsh environmental conditions. Despite lead-free solders showing increased brittleness, their performance supports RoHS compliance without significant degradation in long-term solder joint integrity.

Environmental Impact and Regulations

Tin-lead solder, historically prevalent in electronics, contains lead, a toxic metal regulated under RoHS directives due to its harmful environmental impact, including soil and water contamination. Lead-free solder, primarily composed of tin combined with metals like silver and copper, complies with stringent environmental regulations worldwide by minimizing hazardous waste and reducing exposure to heavy metals. The transition to lead-free solder enhances recyclability and reduces health risks, aligning with global efforts to mitigate pollution and promote sustainable manufacturing.

Health and Safety Considerations

Tin-lead solder poses significant health risks due to lead exposure, which can cause neurological damage and developmental issues, making proper ventilation and protective equipment crucial during use. Lead-free solder, often composed of tin combined with silver, copper, or other metals, reduces these toxic hazards but may require higher temperatures that increase burn risks and inhalation of flux fumes. Compliance with regulatory standards such as RoHS ensures safer handling practices and minimizes environmental and occupational health impacts associated with soldering materials.

Electrical Conductivity and Reliability

Tin-lead solder exhibits superior electrical conductivity compared to lead-free solder alloys due to the presence of lead, which enhances electron flow and reduces resistance. However, lead-free solder, primarily composed of tin combined with metals like silver and copper, offers improved reliability by providing higher melting points and better resistance to thermal fatigue and mechanical stress. Reliability in electronic connections is critical, making lead-free solder preferable in applications requiring long-term durability despite its slightly lower conductivity.

Application Suitability: Industries and Use Cases

Tin-lead solder remains preferred in electronics industries requiring high reliability and repairability, such as aerospace and military applications, due to its lower melting point and superior wetting properties. Lead-free solder, composed primarily of tin with silver and copper, is widely adopted in consumer electronics and automotive sectors to meet environmental regulations like RoHS. Each solder type's application suitability depends on factors like thermal cycles, mechanical stress, and regulatory compliance in specific industries.

Cost Analysis and Economic Factors

Tin-lead solder generally offers lower upfront material costs and superior solderability, reducing manufacturing time and minimizing defects compared to lead-free alternatives. Lead-free solder incurs higher initial expenses due to increased tin content and often requires higher processing temperatures, which can elevate energy consumption and equipment wear. Economic factors also include regulatory compliance costs with lead-free solder, potentially offset by long-term benefits such as reduced environmental impact and improved worker safety.

Future Trends and Innovations in Solder Materials

Tin-lead solder, long favored for its reliable melting point and excellent electrical conductivity, faces declining use due to environmental regulations banning lead in electronics. Future trends emphasize lead-free solder alloys, primarily tin-silver-copper (SAC) compositions, which offer improved thermal fatigue resistance and are being optimized for lower melting temperatures to enhance manufacturing efficiency. Innovations in nano-engineered solder materials and flux formulations aim to boost joint reliability and reduce defects in advanced semiconductor packaging applications.

Tin-lead solder vs lead-free solder Infographic

materialdif.com

materialdif.com