Flow-melted tin offers superior wetting properties and a more uniform coating compared to reflowed tin, enhancing solder joint reliability. Reflowed tin involves melting solder during the assembly process, which can sometimes lead to uneven layers and potential quality inconsistencies. Choosing flow-melted tin ensures better adhesion and durability in electronic components.

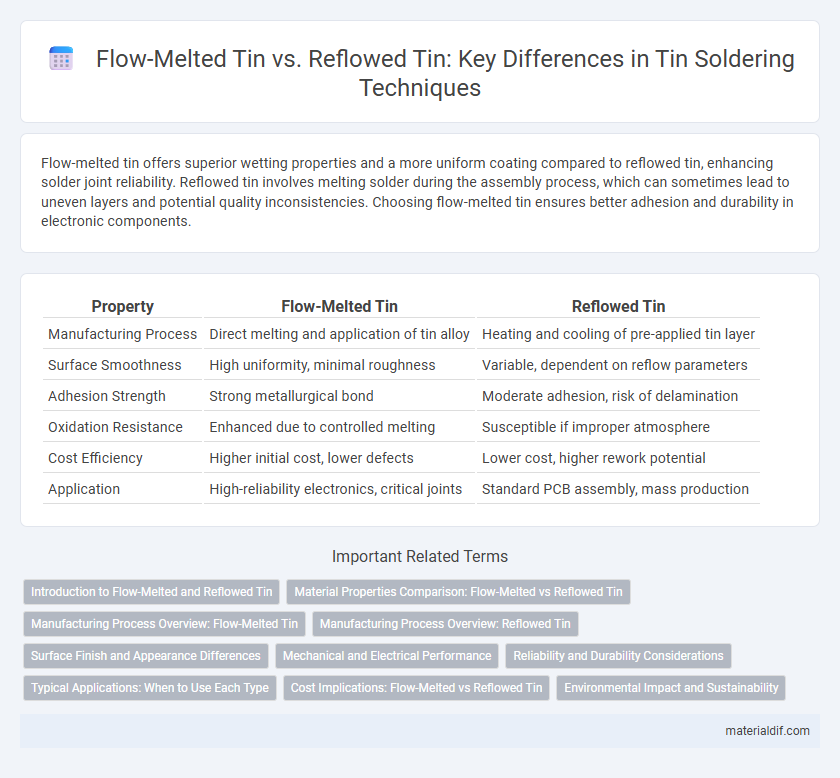

Table of Comparison

| Property | Flow-Melted Tin | Reflowed Tin |

|---|---|---|

| Manufacturing Process | Direct melting and application of tin alloy | Heating and cooling of pre-applied tin layer |

| Surface Smoothness | High uniformity, minimal roughness | Variable, dependent on reflow parameters |

| Adhesion Strength | Strong metallurgical bond | Moderate adhesion, risk of delamination |

| Oxidation Resistance | Enhanced due to controlled melting | Susceptible if improper atmosphere |

| Cost Efficiency | Higher initial cost, lower defects | Lower cost, higher rework potential |

| Application | High-reliability electronics, critical joints | Standard PCB assembly, mass production |

Introduction to Flow-Melted and Reflowed Tin

Flow-melted tin involves melting tin and allowing it to solidify under controlled conditions, producing a uniform microstructure with enhanced purity and mechanical properties. Reflowed tin is typically applied as a coating or solder, where tin is heated to its melting point and then cooled rapidly to form metal joints or surface finishes with precise geometric control. Both processes are crucial in electronics manufacturing, influencing factors like wetting behavior, surface morphology, and joint reliability.

Material Properties Comparison: Flow-Melted vs Reflowed Tin

Flow-melted tin exhibits superior grain structure uniformity and higher tensile strength compared to reflowed tin, resulting in enhanced mechanical reliability for electronic solder joints. Reflowed tin often contains microstructural inconsistencies and increased porosity, which can reduce conductivity and elevate the risk of joint failure under thermal cycling. Material properties such as melting point stability and oxidation resistance are also better maintained in flow-melted tin due to its controlled solidification process.

Manufacturing Process Overview: Flow-Melted Tin

Flow-melted tin involves heating tin above its melting point in a controlled environment, allowing the molten metal to flow evenly over the substrate for uniform coating. This manufacturing process ensures high purity and strong adhesion, resulting in robust, oxidation-resistant surfaces ideal for electronic component protection. The technique contrasts with reflowed tin by emphasizing superior surface finish and consistency in thickness during the initial coating phase.

Manufacturing Process Overview: Reflowed Tin

Reflowed tin involves heating pre-deposited tin coatings until melting occurs, allowing the tin to flow and form a smooth, uniform surface on the substrate. This manufacturing process enhances solderability and improves mechanical properties by reducing voids and surface irregularities compared to traditional electroplated tin. Key parameters include precise temperature control, typically just above tin's melting point of 232degC, and controlled cooling rates to ensure optimal wetting and adhesion.

Surface Finish and Appearance Differences

Flow-melted tin produces a smooth, uniform surface finish with excellent wetting properties, resulting in consistent and reliable solder joints. Reflowed tin often exhibits minor surface irregularities and a slightly duller appearance due to oxide formation during the heating process. The choice between flow-melted and reflowed tin significantly impacts the visual quality and solderability of electronic components.

Mechanical and Electrical Performance

Flow-melted tin exhibits superior mechanical strength and enhanced electrical conductivity compared to reflowed tin due to its homogeneous microstructure and reduced porosity. Reflowed tin often presents increased grain boundaries and potential voids, which can degrade mechanical integrity and increase electrical resistance. Optimizing flow-melting parameters leads to improved solder joint reliability in electronic assemblies.

Reliability and Durability Considerations

Flow-melted tin exhibits superior reliability and durability compared to reflowed tin due to its uniform grain structure and reduced oxidation levels, resulting in enhanced mechanical strength and resistance to thermal cycling. Reflowed tin often shows increased susceptibility to void formation and intermetallic compound growth, which compromises long-term solder joint integrity. Selecting flow-melted tin ensures improved performance in electronic assemblies subjected to harsh environmental and thermal stress conditions.

Typical Applications: When to Use Each Type

Flow-melted tin is ideal for applications requiring uniform coating thickness and superior wettability, often used in wave soldering of printed circuit boards and through-hole components. Reflowed tin suits surface mount technology (SMT) processes where precise component placement and strong solder joints are critical, commonly applied in reflow soldering of fine-pitch components and complex assemblies. Selecting between flow-melted and reflowed tin depends on assembly requirements, component types, and desired coating characteristics for optimal electrical and mechanical performance.

Cost Implications: Flow-Melted vs Reflowed Tin

Flow-melted tin typically incurs higher production costs due to its controlled solidification process, which enhances purity and uniformity but requires specialized equipment. Reflowed tin offers a more cost-effective solution by utilizing existing soldering equipment and shorter processing times, making it suitable for large-scale manufacturing with lower upfront investment. Decision-making between flow-melted and reflowed tin balances the trade-off between initial cost and desired material performance, impacting overall production budgets.

Environmental Impact and Sustainability

Flow-melted tin generally offers a lower environmental impact compared to reflowed tin due to its more efficient melting process that reduces energy consumption and emissions. The reflowed tin method often involves higher thermal energy usage and potential release of volatile compounds, impacting sustainability negatively. Optimizing tin processing techniques by adopting flow-melting can contribute to decreased carbon footprint and improved resource conservation in electronics manufacturing.

Flow-melted Tin vs Reflowed Tin Infographic

materialdif.com

materialdif.com