Terne plate is a steel sheet coated with a thin layer of lead-tin alloy, offering superior corrosion resistance for roofing and industrial applications, while tinplate features a pure tin coating that provides excellent food-grade protection and solderability. Tinplate is commonly used in packaging, especially for cans, due to its non-toxic and rust-resistant properties, whereas terne plate is preferred in environments requiring durability against weather and chemical exposure. Choosing between terne plate and tinplate depends on the specific requirements of corrosion resistance, safety standards, and intended use.

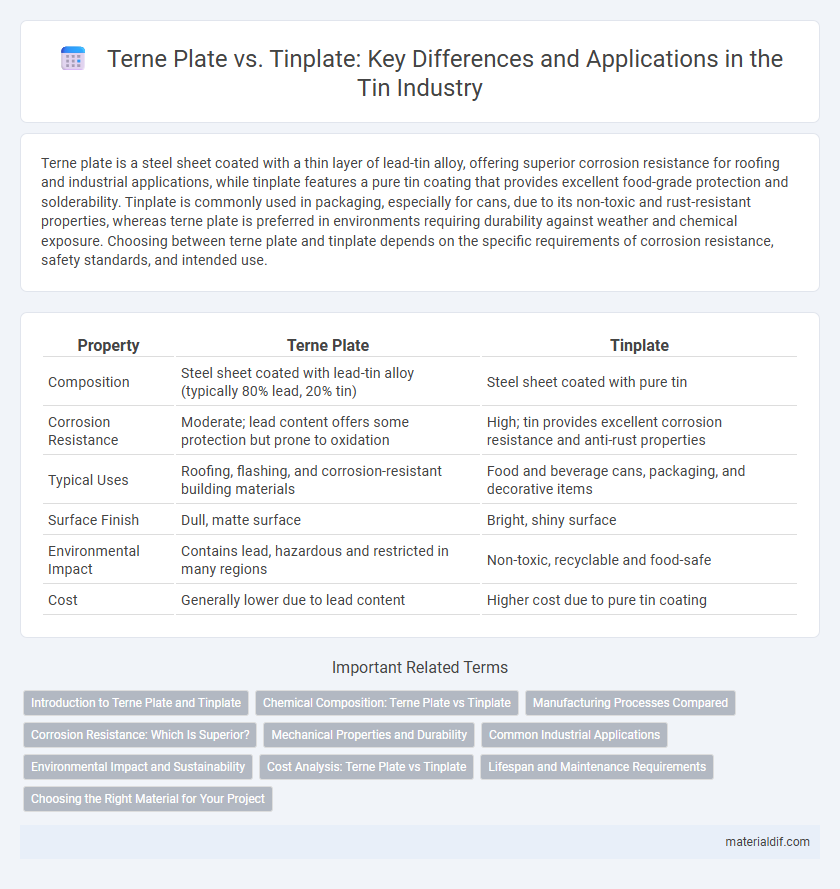

Table of Comparison

| Property | Terne Plate | Tinplate |

|---|---|---|

| Composition | Steel sheet coated with lead-tin alloy (typically 80% lead, 20% tin) | Steel sheet coated with pure tin |

| Corrosion Resistance | Moderate; lead content offers some protection but prone to oxidation | High; tin provides excellent corrosion resistance and anti-rust properties |

| Typical Uses | Roofing, flashing, and corrosion-resistant building materials | Food and beverage cans, packaging, and decorative items |

| Surface Finish | Dull, matte surface | Bright, shiny surface |

| Environmental Impact | Contains lead, hazardous and restricted in many regions | Non-toxic, recyclable and food-safe |

| Cost | Generally lower due to lead content | Higher cost due to pure tin coating |

Introduction to Terne Plate and Tinplate

Terne plate is a steel sheet coated primarily with a lead-tin alloy, known for its corrosion resistance and flexibility, frequently used in roofing and automotive applications. Tinplate consists of thin steel sheets coated with pure tin, providing excellent solderability and corrosion protection, commonly applied in food packaging and cans. Both materials utilize tin coatings but differ significantly in alloy composition and surface finish, influencing their distinct industrial uses and performance characteristics.

Chemical Composition: Terne Plate vs Tinplate

Terne plate primarily consists of a steel base coated with an alloy of lead and tin, typically around 80% lead and 20% tin, enhancing its corrosion resistance and flexibility. Tinplate features a thin layer of pure tin, usually over 99.8% tin content, electroplated on a steel sheet, providing superior food safety and solderability. The distinct chemical compositions determine their specific industrial applications, with terne plate suited for roofing and oil containers, while tinplate is favored in food packaging and can manufacturing.

Manufacturing Processes Compared

Terne plate and tinplate differ primarily in their manufacturing processes and coating materials; tinplate is steel coated with a thin layer of pure tin via electroplating, providing excellent corrosion resistance and a smooth, bright finish optimal for food packaging. Terne plate involves hot-dipping steel in a lead-tin alloy, typically consisting of around 80% lead and 20% tin, resulting in a duller surface with higher corrosion resistance suited for roofing and industrial applications. The electroplating process in tinplate ensures a uniform, controlled coating thickness, whereas terne plate's hot-dip method produces a thicker, less uniform coating that enhances weather durability.

Corrosion Resistance: Which Is Superior?

Terne plate exhibits superior corrosion resistance compared to traditional tinplate due to its unique alloy coating of lead and tin, which forms a more protective barrier against rust and chemical exposure. Tinplate, coated with pure tin, provides adequate corrosion resistance but is more susceptible to damage and corrosion in harsh environments. The lead-tin alloy in terne plate enhances durability in industrial applications where prolonged exposure to moisture and corrosive elements occurs.

Mechanical Properties and Durability

Terne plate features a lead-tin alloy coating that provides superior flexibility and impact resistance compared to the pure tin coating of tinplate, enhancing its mechanical properties for applications requiring bending and shaping. Tinplate exhibits higher corrosion resistance and durability in food packaging due to its pure tin layer, which prevents rust and contamination effectively. Choosing between terne plate and tinplate depends on balancing mechanical strength needs with long-term durability in specific environmental conditions.

Common Industrial Applications

Terne plate, coated with a lead-tin alloy, is widely used in roofing, automotive fuel tanks, and industrial containers due to its enhanced corrosion resistance and solderability. Tinplate, consisting of thin steel sheets coated with pure tin, is primarily utilized in food packaging, beverage cans, and pharmaceutical containers for its non-toxic, antimicrobial surface and excellent corrosion protection. Both materials serve critical roles in manufacturing but are selected based on specific industrial requirements such as environmental exposure and regulatory standards.

Environmental Impact and Sustainability

Terne plate, typically made by coating steel with a tin-lead alloy, poses significant environmental concerns due to lead's toxicity and challenges in recycling, contributing to soil and water contamination. In contrast, tinplate, coated with pure tin, offers enhanced recyclability and lower toxicity, making it a more sustainable choice for packaging and industrial uses. Transitioning to tinplate reduces hazardous waste and supports circular economy principles, aligning with global environmental regulations and sustainability goals.

Cost Analysis: Terne Plate vs Tinplate

Terne plate typically costs less than tinplate due to its simpler manufacturing process, which involves coating steel with a lead-tin alloy rather than pure tin. Tinplate provides superior corrosion resistance and a shinier finish, often justifying its higher price for applications requiring durability and aesthetics. Cost analysis reveals terne plate as a budget-friendly option for industrial uses where visual appeal and long-term corrosion resistance are less critical.

Lifespan and Maintenance Requirements

Terne plate, composed of a lead-tin alloy coated steel, typically has a shorter lifespan than tinplate due to lead's susceptibility to corrosion over time, requiring more frequent maintenance to prevent rust and degradation. Tinplate, coated with pure tin, offers superior corrosion resistance and a longer lifespan, minimizing the need for regular upkeep in environments prone to moisture and chemical exposure. Choosing tinplate over terne plate reduces maintenance efforts and extends durability, making it ideal for applications demanding long-term corrosion protection.

Choosing the Right Material for Your Project

Terne plate features a lead-tin alloy coating that offers excellent corrosion resistance and is ideal for roofing, flashing, and decorative applications where durability against harsh weather is crucial. Tinplate, composed of steel coated with pure tin, provides superior food safety, making it the preferred choice for packaging, especially in the food and beverage industry. Selecting between terne plate and tinplate depends on project requirements: terne plate excels in structural and outdoor uses, while tinplate is optimized for hygienic, non-corrosive environments.

Terne Plate vs Tinplate Infographic

materialdif.com

materialdif.com