Reflowed tin offers improved solder joint reliability and reduced surface oxidation compared to as-plated tin, enhancing electronic component performance. The reflow process smooths the tin surface, eliminating irregularities and providing better wetting properties during soldering. This results in stronger connections and decreased risk of defects in electronic assemblies.

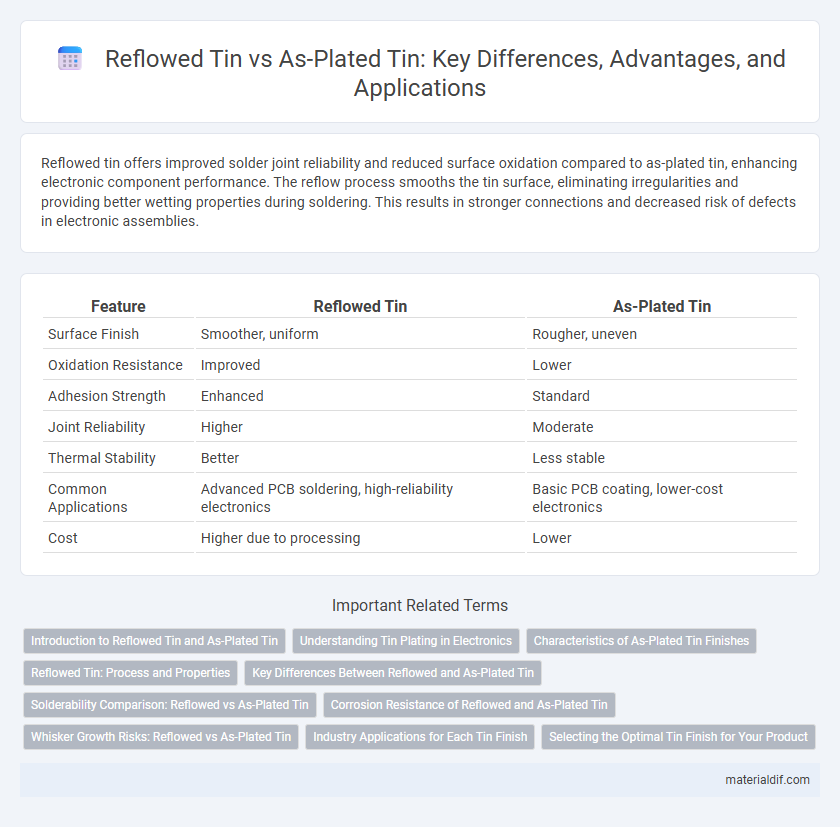

Table of Comparison

| Feature | Reflowed Tin | As-Plated Tin |

|---|---|---|

| Surface Finish | Smoother, uniform | Rougher, uneven |

| Oxidation Resistance | Improved | Lower |

| Adhesion Strength | Enhanced | Standard |

| Joint Reliability | Higher | Moderate |

| Thermal Stability | Better | Less stable |

| Common Applications | Advanced PCB soldering, high-reliability electronics | Basic PCB coating, lower-cost electronics |

| Cost | Higher due to processing | Lower |

Introduction to Reflowed Tin and As-Plated Tin

Reflowed tin enhances solder joint reliability by undergoing controlled melting and solidification, improving surface morphology compared to as-plated tin, which is directly deposited on the substrate without thermal treatment. As-plated tin often presents a matte finish with potential surface irregularities, while reflowed tin exhibits a smoother, more uniform crystalline structure, reducing the risk of whisker formation and improving electrical conductivity. This thermal process in reflowed tin optimizes wettability and adhesion, making it preferable in high-performance electronic assemblies over the standard as-plated tin finish.

Understanding Tin Plating in Electronics

Reflowed tin plating in electronics involves melting and solidifying the tin layer, which enhances its adhesion and smooths out surface irregularities compared to as-plated tin. This process improves solderability by reducing oxidation and creating a more uniform surface, critical for reliable electrical connections on printed circuit boards (PCBs). Understanding the differences between reflowed and as-plated tin is essential for optimizing solder joint quality and long-term component performance.

Characteristics of As-Plated Tin Finishes

As-plated tin finishes exhibit a bright, matte appearance with excellent solderability and corrosion resistance, making them ideal for printed circuit board surfaces. This finish typically consists of a thin, uniform layer of tin applied through electroplating, which provides superior wetting properties compared to reflowed tin. The as-plated tin layer offers consistent thickness and smoothness, enhancing electrical conductivity and minimizing the risk of whisker growth during initial manufacturing stages.

Reflowed Tin: Process and Properties

Reflowed tin involves melting and solidifying plated tin to enhance the metallurgical bond and improve surface quality, reducing the risk of whisker growth and corrosion. The reflow process refines grain structure, resulting in a smoother, more uniform finish with improved solderability and mechanical strength compared to as-plated tin. This method also promotes better intermetallic compound formation, which increases the reliability of electronic components in harsh environments.

Key Differences Between Reflowed and As-Plated Tin

Reflowed tin features a smooth, uniform surface achieved through a melting and solidification process, enhancing solderability and reducing the risk of solder voids, unlike as-plated tin which has a rougher, grainy texture due to electrochemical deposition. As-plated tin maintains its original plating morphology, making it more prone to surface oxidation and less consistent wetting during soldering compared to reflowed tin. The thermal stability and mechanical reliability of reflowed tin are superior, contributing to improved joint integrity in electronic assemblies.

Solderability Comparison: Reflowed vs As-Plated Tin

Reflowed tin demonstrates improved solderability compared to as-plated tin due to the formation of a uniform intermetallic compound layer that enhances wetting and bond strength. As-plated tin often contains oxides and surface contaminants that hinder solder flow and reduce joint reliability. Evaluations show reflowed tin consistently achieves lower soldering defect rates and stronger mechanical integrity in electronic assemblies.

Corrosion Resistance of Reflowed and As-Plated Tin

Reflowed tin exhibits superior corrosion resistance compared to as-plated tin due to its smoother, more uniform surface, which reduces sites for corrosion initiation. The reflow process enhances the metallurgical bonding and eliminates voids present in as-plated tin layers, significantly improving durability in harsh environments. Laboratory tests show reflowed tin layers resist chloride-induced corrosion and sulfide tarnishing more effectively than their as-plated counterparts.

Whisker Growth Risks: Reflowed vs As-Plated Tin

Reflowed tin exhibits a reduced whisker growth risk compared to as-plated tin due to the annealing effect that relieves internal stresses within the tin layer. Whiskers, fine metallic filaments that can cause short circuits, are more prone to develop on as-plated tin surfaces where residual stress remains high. Studies indicate that the thermal cycling involved in the reflow process stabilizes the tin microstructure, significantly mitigating the propensity for whisker formation.

Industry Applications for Each Tin Finish

Reflowed tin, characterized by its smoother surface and enhanced solderability, is widely used in high-reliability electronics such as automotive and aerospace circuit boards where consistent solder joints are critical. As-plated tin, with its original electroplated finish, is preferred in consumer electronics and general-purpose applications where cost efficiency and adequate corrosion resistance are essential. Both finishes optimize industry-specific performance by balancing factors like solderability, corrosion protection, and mechanical durability.

Selecting the Optimal Tin Finish for Your Product

Reflowed tin offers enhanced solderability and improved surface planarity compared to as-plated tin, making it ideal for complex PCB assemblies requiring reliable joint formation. As-plated tin provides a cost-effective, corrosion-resistant finish but may present increased risk of tin whisker growth and poorer wetting characteristics. Choosing between reflowed and as-plated tin finishes depends on factors such as assembly complexity, thermal budget, and long-term reliability demands of the electronic product.

Reflowed tin vs as-plated tin Infographic

materialdif.com

materialdif.com