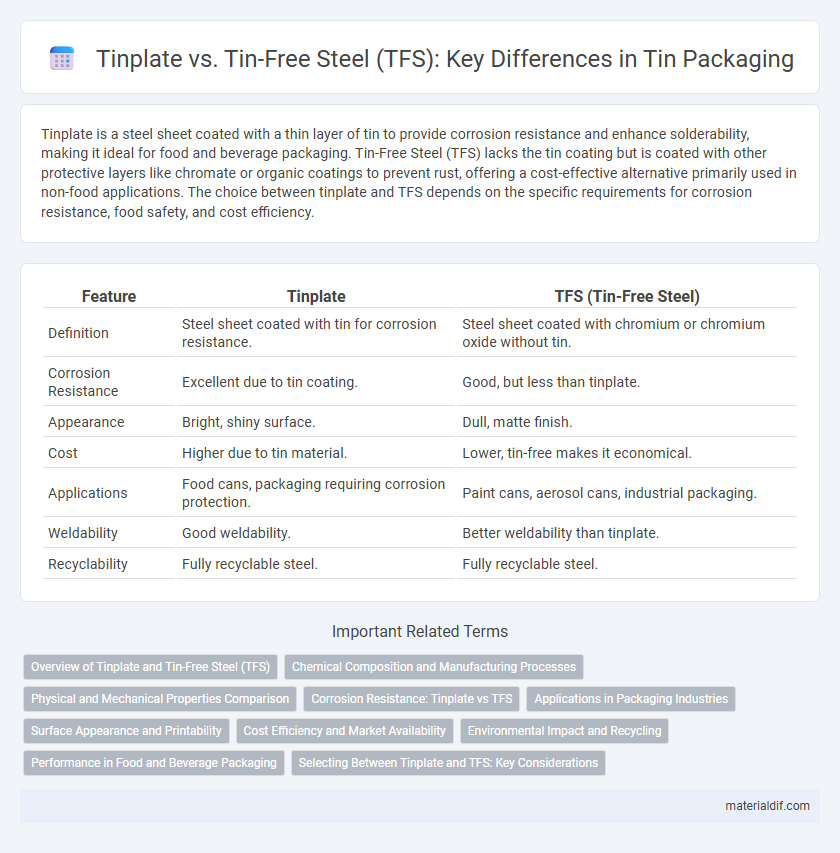

Tinplate is a steel sheet coated with a thin layer of tin to provide corrosion resistance and enhance solderability, making it ideal for food and beverage packaging. Tin-Free Steel (TFS) lacks the tin coating but is coated with other protective layers like chromate or organic coatings to prevent rust, offering a cost-effective alternative primarily used in non-food applications. The choice between tinplate and TFS depends on the specific requirements for corrosion resistance, food safety, and cost efficiency.

Table of Comparison

| Feature | Tinplate | TFS (Tin-Free Steel) |

|---|---|---|

| Definition | Steel sheet coated with tin for corrosion resistance. | Steel sheet coated with chromium or chromium oxide without tin. |

| Corrosion Resistance | Excellent due to tin coating. | Good, but less than tinplate. |

| Appearance | Bright, shiny surface. | Dull, matte finish. |

| Cost | Higher due to tin material. | Lower, tin-free makes it economical. |

| Applications | Food cans, packaging requiring corrosion protection. | Paint cans, aerosol cans, industrial packaging. |

| Weldability | Good weldability. | Better weldability than tinplate. |

| Recyclability | Fully recyclable steel. | Fully recyclable steel. |

Overview of Tinplate and Tin-Free Steel (TFS)

Tinplate is steel sheet coated with a thin layer of tin to provide corrosion resistance and enhance solderability, commonly used in food and beverage packaging. Tin-Free Steel (TFS) features a chromate or chromium oxide coating instead of tin, offering excellent corrosion resistance without the cost of tin while maintaining structural strength. Both materials serve critical roles in packaging, with tinplate favored for direct food contact due to its non-toxicity and TFS popular in applications requiring manufacturing efficiency and economic advantages.

Chemical Composition and Manufacturing Processes

Tinplate consists of a thin steel sheet coated with a layer of tin, providing excellent corrosion resistance and solderability, commonly produced through electrolytic tinning. In contrast, Tin-Free Steel (TFS) uses electroplated chromium or chromium oxide instead of tin, relying on a passivation layer to protect against rust while ensuring compatibility with food and beverage packaging. The chemical composition of the base steel remains similar, primarily low-carbon steel, but the key difference lies in the surface treatment--tin plating for tinplate versus chromium-based coatings for TFS--affecting manufacturing processes and end-use performance.

Physical and Mechanical Properties Comparison

Tinplate offers superior corrosion resistance and excellent formability due to its thin tin coating, making it ideal for food and beverage packaging. Tin-Free Steel (TFS) lacks the tin coating but features a chromium or chromium oxide layer, providing higher rigidity and better weldability compared to tinplate. While tinplate exhibits greater ductility and surface smoothness, TFS excels in mechanical strength and resistance to high-temperature applications.

Corrosion Resistance: Tinplate vs TFS

Tinplate exhibits superior corrosion resistance due to its thin layer of tin that acts as a protective barrier, effectively preventing rust and enhancing longevity in packaging applications. In contrast, Tin-Free Steel (TFS) relies on a chromate conversion coating which offers less robust protection against corrosion, especially in acidic or high-moisture environments. For industries requiring enhanced durability against oxidation, tinplate remains the preferred choice, while TFS is often selected for cost-sensitive applications where moderate corrosion resistance is sufficient.

Applications in Packaging Industries

Tinplate is extensively used in packaging industries for food and beverage cans due to its excellent corrosion resistance and printability, making it ideal for preserving product quality. Tin-Free Steel (TFS) offers a cost-effective alternative with a chromium-based coating, commonly utilized in packaging applications where decorative appearance and moderate corrosion resistance are required. Both materials are essential in manufacturing containers and closures, with tinplate preferred for its superior food safety properties and TFS favored in packaging that demands economical solutions without direct food contact.

Surface Appearance and Printability

Tinplate offers a bright, smooth surface with excellent corrosion resistance, which enhances print quality and visual appeal for packaging applications. TFS (Tin-Free Steel) features a matte finish that provides good print adhesion but may result in less vibrant colors due to its lack of a shiny surface. Both materials support various printing technologies, but tinplate's glossy surface typically delivers sharper, more vivid graphics compared to the more subdued appearance of TFS.

Cost Efficiency and Market Availability

Tinplate offers superior corrosion resistance due to its thin tin coating, making it ideal for food and beverage packaging despite higher costs. TFS (Tin-Free Steel) provides a cost-efficient alternative with a chromium-based coating that reduces material expenses but requires additional surface treatment for corrosion protection. Market availability favors tinplate in consumer goods, while TFS dominates automotive and industrial sectors due to cost advantages and tailored performance.

Environmental Impact and Recycling

Tinplate and Tin-Free Steel (TFS) differ significantly in environmental impact and recycling efficiency. Tinplate, coated with a thin layer of tin, offers superior corrosion resistance and is highly recyclable through established steel recycling streams, reducing waste and lowering energy consumption during remanufacturing. TFS, lacking the tin coating, presents challenges in corrosion protection but benefits from a simpler, less resource-intensive production process and can be recycled efficiently, although it may require additional surface treatment to prevent rust in certain applications.

Performance in Food and Beverage Packaging

Tinplate offers superior corrosion resistance and excellent barrier properties, making it ideal for preserving flavor and extending shelf life in food and beverage packaging. TFS (Tin-Free Steel) provides enhanced weldability and cost-efficiency, but requires additional protective coatings to achieve comparable corrosion resistance. Choosing tinplate ensures better durability and product safety where moisture and acidic content are critical factors.

Selecting Between Tinplate and TFS: Key Considerations

Selecting between tinplate and tin-free steel (TFS) hinges on factors such as corrosion resistance, cost efficiency, and environmental impact. Tinplate offers superior corrosion protection due to its thin tin coating, making it ideal for food packaging and applications requiring direct contact with contents. TFS provides a more economical and recyclable alternative, favored in manufacturing sectors prioritizing cost reduction and sustainability without compromising structural integrity.

Tinplate vs TFS (Tin-Free Steel) Infographic

materialdif.com

materialdif.com