Pure tin offers excellent corrosion resistance and is highly malleable, making it ideal for applications requiring non-toxic, food-safe coatings. Alloyed tin, often combined with metals like copper or silver, enhances mechanical strength and wear resistance, extending the durability of components under stress. Choosing between pure and alloyed tin depends on the balance between flexibility and robustness needed for specific industrial or decorative uses.

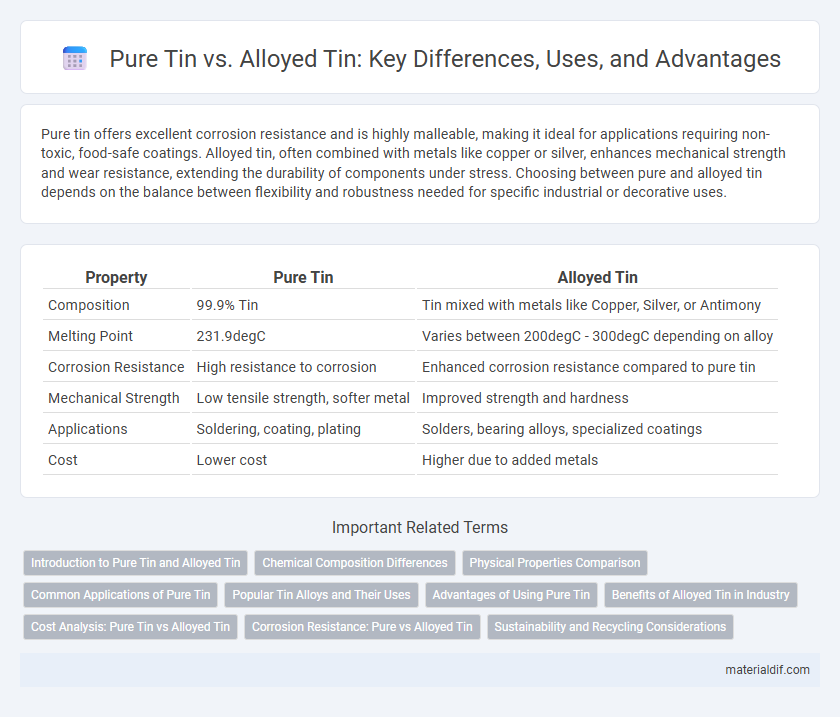

Table of Comparison

| Property | Pure Tin | Alloyed Tin |

|---|---|---|

| Composition | 99.9% Tin | Tin mixed with metals like Copper, Silver, or Antimony |

| Melting Point | 231.9degC | Varies between 200degC - 300degC depending on alloy |

| Corrosion Resistance | High resistance to corrosion | Enhanced corrosion resistance compared to pure tin |

| Mechanical Strength | Low tensile strength, softer metal | Improved strength and hardness |

| Applications | Soldering, coating, plating | Solders, bearing alloys, specialized coatings |

| Cost | Lower cost | Higher due to added metals |

Introduction to Pure Tin and Alloyed Tin

Pure tin, consisting of over 99.9% tin content, exhibits excellent corrosion resistance and electrical conductivity, making it ideal for applications in electronics and coatings. Alloyed tin combines tin with metals like copper, silver, or antimony to enhance mechanical strength, hardness, and thermal stability for industrial uses such as soldering and bearing materials. Understanding the differences in composition and properties helps optimize material selection based on performance requirements in manufacturing and engineering.

Chemical Composition Differences

Pure tin consists almost entirely of the element Sn, typically exceeding 99.9% purity, with minimal impurities affecting its physical properties. Alloyed tin incorporates additional metals such as copper, silver, or antimony to enhance mechanical strength, corrosion resistance, and solderability, resulting in varied chemical compositions tailored to specific industrial applications. The presence of alloying elements alters the microstructure and melting point of tin, distinguishing it fundamentally from its pure counterpart.

Physical Properties Comparison

Pure tin exhibits a melting point of 231.9degC and maintains excellent ductility and electrical conductivity, making it suitable for delicate applications. Alloyed tin, often combined with copper or silver, shows increased hardness and tensile strength while slightly reducing electrical conductivity and melting point to around 220-230degC. The density of pure tin stands at 7.31 g/cm3, whereas alloys typically present enhanced mechanical stability with minor variations in density depending on the alloying elements.

Common Applications of Pure Tin

Pure tin is widely used in soldering applications due to its excellent corrosion resistance and low melting point, making it essential for electronic circuit assembly. It is also applied in coating steel cans for food preservation, preventing contamination and extending shelf life. Furthermore, pure tin serves as a protective layer in plating processes to enhance durability and maintain product integrity in various industrial applications.

Popular Tin Alloys and Their Uses

Popular tin alloys include bronze, an alloy of tin and copper widely used in coins, sculptures, and musical instruments due to its strength and corrosion resistance. Solder, composed primarily of tin and lead or tin and silver, is essential in electronics for creating strong, conductive joints. Pewter, a mixture of tin with small amounts of copper and antimony, maintains popularity in decorative items and tableware because of its malleability and attractive finish.

Advantages of Using Pure Tin

Pure tin offers superior corrosion resistance and excellent solderability compared to alloyed tin, making it ideal for electronic components and food packaging. Its non-toxic, lead-free nature enhances environmental safety and regulatory compliance in various applications. High purity ensures consistent electrical conductivity, improving performance in sensitive electronic circuits.

Benefits of Alloyed Tin in Industry

Alloyed tin offers superior corrosion resistance and enhanced mechanical strength compared to pure tin, making it ideal for industrial applications such as soldering and plating. The addition of metals like copper, silver, or bismuth improves wear resistance and thermal stability, extending the lifespan of electronic components and coatings. These benefits optimize performance in demanding environments, reducing maintenance costs and increasing product reliability.

Cost Analysis: Pure Tin vs Alloyed Tin

Pure tin typically incurs higher production costs due to its refinement process and material purity standards, making it more expensive than alloyed tin. Alloyed tin, combined with metals like copper or silver, reduces overall material costs while enhancing mechanical properties and durability. Cost efficiency in alloyed tin is driven by optimized resource usage and improved performance, offering better value in industrial applications.

Corrosion Resistance: Pure vs Alloyed Tin

Pure tin exhibits moderate corrosion resistance but is prone to "tin pest" and surface oxidation in harsh environments, limiting its durability. Alloyed tin, combined with metals such as copper, silver, or bismuth, significantly enhances corrosion resistance by forming a more stable and protective oxide layer. These tin alloys provide superior protection against moisture, acids, and soldering fluxes, making them ideal for electronic components and food packaging applications.

Sustainability and Recycling Considerations

Pure tin offers high recyclability due to its simple composition, facilitating efficient recovery processes and reducing environmental impact. Alloyed tin, often combined with metals like copper or silver, enhances mechanical properties but complicates recycling by requiring more energy-intensive separation techniques. Choosing pure tin supports sustainability by minimizing resource consumption and promoting circular economy practices within the metal industry.

Pure Tin vs Alloyed Tin Infographic

materialdif.com

materialdif.com