Hot-dipped tin coating offers superior corrosion resistance and a thicker, more uniform layer compared to electrolytic tin, making it ideal for harsh environments. Electrolytic tin provides a smoother, thinner coating with better solderability and is preferred in applications requiring precision and minimal layer thickness. Choosing between hot-dipped and electrolytic tin depends on balancing durability needs with surface finish quality for specific industrial uses.

Table of Comparison

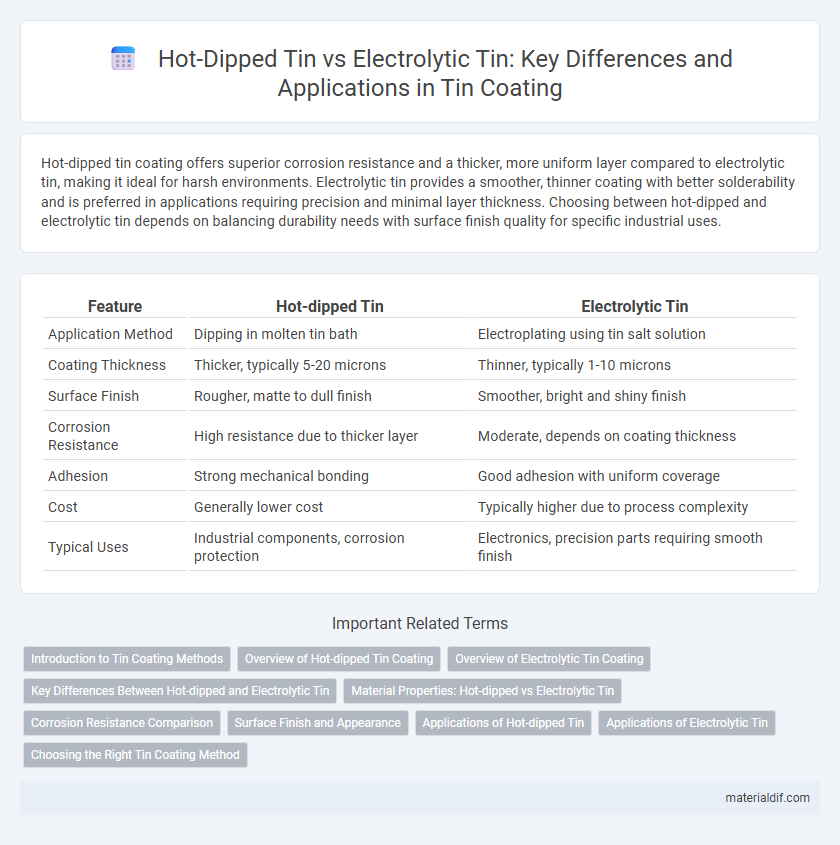

| Feature | Hot-dipped Tin | Electrolytic Tin |

|---|---|---|

| Application Method | Dipping in molten tin bath | Electroplating using tin salt solution |

| Coating Thickness | Thicker, typically 5-20 microns | Thinner, typically 1-10 microns |

| Surface Finish | Rougher, matte to dull finish | Smoother, bright and shiny finish |

| Corrosion Resistance | High resistance due to thicker layer | Moderate, depends on coating thickness |

| Adhesion | Strong mechanical bonding | Good adhesion with uniform coverage |

| Cost | Generally lower cost | Typically higher due to process complexity |

| Typical Uses | Industrial components, corrosion protection | Electronics, precision parts requiring smooth finish |

Introduction to Tin Coating Methods

Hot-dipped tin coating involves immersing a metal substrate in molten tin, creating a thick, durable layer that offers excellent corrosion resistance and solderability. Electrolytic tin coating, or electroplating, uses an electric current to deposit a thin, uniform layer of tin onto the substrate, enhancing surface smoothness and precision control over coating thickness. Both methods are critical in electronics and packaging industries, where tailored tin layer properties directly impact product performance and reliability.

Overview of Hot-dipped Tin Coating

Hot-dipped tin coating involves immersing a metal substrate into molten tin, creating a robust and uniform layer that enhances corrosion resistance and solderability. This process forms a thicker and more durable coating compared to electrolytic tin, making it especially suitable for harsh environments and heavy-duty applications. Hot-dipped tin coatings commonly exhibit better adhesion and long-term protection, crucial for automotive and industrial metal parts.

Overview of Electrolytic Tin Coating

Electrolytic tin coating involves the deposition of pure tin onto metal surfaces through an electrochemical process, offering precise thickness control and uniform coverage. This coating method enhances corrosion resistance and solderability, making it ideal for electronic components and food packaging applications. Compared to hot-dipped tin, electrolytic tin provides a smoother finish and improved adhesion, which contributes to better long-term performance in sensitive environments.

Key Differences Between Hot-dipped and Electrolytic Tin

Hot-dipped tin coating involves immersing the substrate in molten tin, creating a thicker, more durable layer ideal for corrosion resistance and mechanical protection. Electrolytic tin plating uses an electrical current to deposit a thin, uniform tin layer with superior brightness and surface smoothness, suitable for precise electronic applications. The key differences lie in coating thickness, bonding strength, and surface finish, where hot-dipped tin offers robustness, and electrolytic tin provides finer control and aesthetic appeal.

Material Properties: Hot-dipped vs Electrolytic Tin

Hot-dipped tin coatings exhibit superior corrosion resistance due to their thicker and more uniform layer compared to electrolytic tin, which tends to have a thinner, more controlled deposition. The microstructure of hot-dipped tin is typically coarser with better adhesion to substrates like steel, enhancing durability in harsh environments. Electrolytic tin provides a smoother surface finish and greater precision in thickness control, making it ideal for applications requiring fine detail and minimal surface roughness.

Corrosion Resistance Comparison

Hot-dipped tin coatings provide superior corrosion resistance due to their thicker, more uniform layer that effectively protects the underlying metal from oxidation and harsh environmental exposure. Electrolytic tin coatings, while thinner and more precise, offer less robust protection and are more susceptible to wear and corrosion over time. The choice between hot-dipped and electrolytic tin depends on the required durability and environmental conditions of the application.

Surface Finish and Appearance

Hot-dipped tin provides a thicker, more uniform coating with a matte finish that enhances corrosion resistance, making it suitable for industrial applications where durability is critical. Electrolytic tin offers a thinner, highly uniform, and bright, shiny surface that improves solderability and is preferred in electronics for its aesthetic appeal and precision. Surface finish differences impact appearance, with hot-dipped tin presenting a rougher texture and electrolytic tin delivering a smooth, reflective coating.

Applications of Hot-dipped Tin

Hot-dipped tin coating is extensively used in the packaging industry, particularly for food and beverage cans, due to its strong corrosion resistance and excellent adhesion to steel surfaces. This method provides a thick, durable layer that enhances the longevity of metal products exposed to harsh environments, making it ideal for automotive and electrical components. Hot-dipped tin also offers superior solderability and protection against oxidation, crucial for electronic connectors and cold-rolled steel applications.

Applications of Electrolytic Tin

Electrolytic tin is extensively used in the electronics industry for plating printed circuit boards (PCBs) due to its superior solderability and corrosion resistance. This method allows precise thickness control, making it ideal for components requiring high-quality surface finishes and reliable electrical contacts. Its application extends to connectors and semiconductor packaging where consistent, thin deposits are critical for performance.

Choosing the Right Tin Coating Method

Hot-dipped tin coating offers superior corrosion resistance and mechanical durability by forming a thick, uniform layer through molten tin immersion, ideal for heavy-duty applications like automotive and electrical connectors. Electrolytic tin plating provides a thinner, more controlled coating with high precision and better surface finish, suitable for delicate electronic components and fine circuitry. Selecting the right tin coating method depends on application requirements such as corrosion protection level, mechanical wear, and electrical conductivity.

Hot-dipped Tin vs Electrolytic Tin Infographic

materialdif.com

materialdif.com