Duplex tin coating offers superior corrosion resistance by combining two layers of tin, enhancing durability and lifespan compared to simplex tin coating, which involves a single tin layer. This dual-layer protection minimizes the risk of substrate exposure, making it ideal for applications requiring long-term reliability in harsh environments. Simplex tin coating suits less demanding conditions but may require more frequent maintenance to prevent rust and degradation.

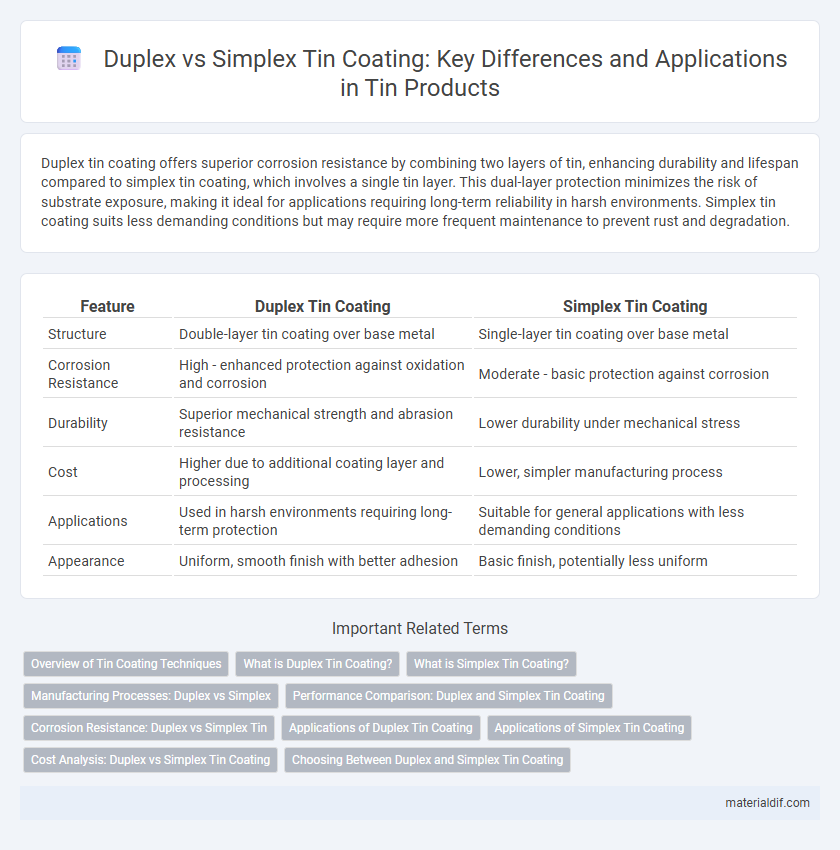

Table of Comparison

| Feature | Duplex Tin Coating | Simplex Tin Coating |

|---|---|---|

| Structure | Double-layer tin coating over base metal | Single-layer tin coating over base metal |

| Corrosion Resistance | High - enhanced protection against oxidation and corrosion | Moderate - basic protection against corrosion |

| Durability | Superior mechanical strength and abrasion resistance | Lower durability under mechanical stress |

| Cost | Higher due to additional coating layer and processing | Lower, simpler manufacturing process |

| Applications | Used in harsh environments requiring long-term protection | Suitable for general applications with less demanding conditions |

| Appearance | Uniform, smooth finish with better adhesion | Basic finish, potentially less uniform |

Overview of Tin Coating Techniques

Duplex tin coating combines a base layer of electroplated tin with an additional organic or metallic top layer, enhancing corrosion resistance and solderability compared to simplex tin coatings that consist of a single tin layer. Simplex tin coatings are typically applied through electroplating or hot-dip methods, offering basic protection and conductivity primarily for electronic components. Duplex coatings provide superior durability and longevity in harsh environments by leveraging multilayer structures that optimize surface properties and prevent oxidation.

What is Duplex Tin Coating?

Duplex tin coating involves applying two layers of tin for enhanced corrosion resistance and durability compared to simplex tin coating, which has a single tin layer. The duplex process typically includes an initial tin plating followed by a second tin layer or an additional protective coating, improving adhesion and protection against oxidation. This method is widely used in electronics and packaging industries to extend the lifespan of metal substrates under harsh environmental conditions.

What is Simplex Tin Coating?

Simplex tin coating involves applying a single layer of tin onto a metal surface, typically steel or copper, to enhance corrosion resistance and solderability. This coating method provides a basic protective barrier but lacks the additional durability and performance benefits found in duplex tin coatings, which use two layers. Simplex tin coatings are commonly used in applications where cost efficiency and moderate protection against oxidation are sufficient.

Manufacturing Processes: Duplex vs Simplex

Duplex tin coating involves a two-step manufacturing process where the substrate is first coated with an Ni or Cu barrier layer followed by a tin layer, enhancing corrosion resistance and solderability. Simplex tin coating applies a single layer of tin directly on the substrate, resulting in a simpler and faster production but with lower protective properties. The duplex process typically requires more precise control and increased production time, positioned for high-performance applications demanding durability.

Performance Comparison: Duplex and Simplex Tin Coating

Duplex tin coating offers superior corrosion resistance and durability compared to simplex tin coating, making it ideal for harsh environmental conditions. The dual-layer structure in duplex coatings enhances adhesion and extends the service life of the coated substrate. Simplex tin coating provides basic protection suitable for less demanding applications but lacks the robust performance characteristics of duplex systems.

Corrosion Resistance: Duplex vs Simplex Tin

Duplex tin coating provides superior corrosion resistance compared to simplex tin coating due to its dual-layer structure that combines a base layer with a protective top layer, enhancing barrier protection against oxidation and environmental factors. Simplex tin coating, consisting of a single layer, offers basic corrosion resistance but is more susceptible to wear and environmental degradation over time. Industrial applications requiring prolonged durability and exposure to harsh conditions often prefer duplex tin coatings for their enhanced protective performance.

Applications of Duplex Tin Coating

Duplex tin coating combines electroplated tin with an electrolytic tin layer, enhancing corrosion resistance and solderability compared to simplex coatings. It is widely used in printed circuit boards (PCBs) and electronic connectors where long-term durability and strong electrical performance are critical. Industries such as automotive electronics, telecommunications, and consumer gadgets benefit from duplex tin coatings for reliable protection against oxidation and mechanical wear.

Applications of Simplex Tin Coating

Simplex tin coating is widely used in the food packaging industry for cans, providing corrosion resistance and food safety without the complexity of duplex systems. It is also preferred in electrical components where a uniform tin layer ensures effective conductivity and solderability. Industrial applications benefit from simplex tin coating's cost-efficiency and sufficient protection against oxidation for numerous metal substrates.

Cost Analysis: Duplex vs Simplex Tin Coating

Duplex tin coating typically incurs higher initial costs due to its dual-layer application process, enhancing corrosion resistance and extending product lifespan compared to simplex tin coating. Simplex tin coating offers a cost-effective solution with a single layer, suitable for applications where moderate corrosion protection suffices. Evaluating total cost of ownership reveals duplex coating often yields long-term savings by reducing maintenance and replacement expenses.

Choosing Between Duplex and Simplex Tin Coating

Duplex tin coating offers superior corrosion resistance by combining electroplated and hot-dipped layers, ideal for applications requiring enhanced durability. Simplex tin coating, typically a single electroplated layer, provides cost-effective protection suitable for environments with moderate exposure to moisture and oxidation. Choosing between duplex and simplex tin coatings depends on factors such as budget constraints, environmental conditions, and the required lifespan of the coated material.

Duplex Tin Coating vs Simplex Tin Coating Infographic

materialdif.com

materialdif.com