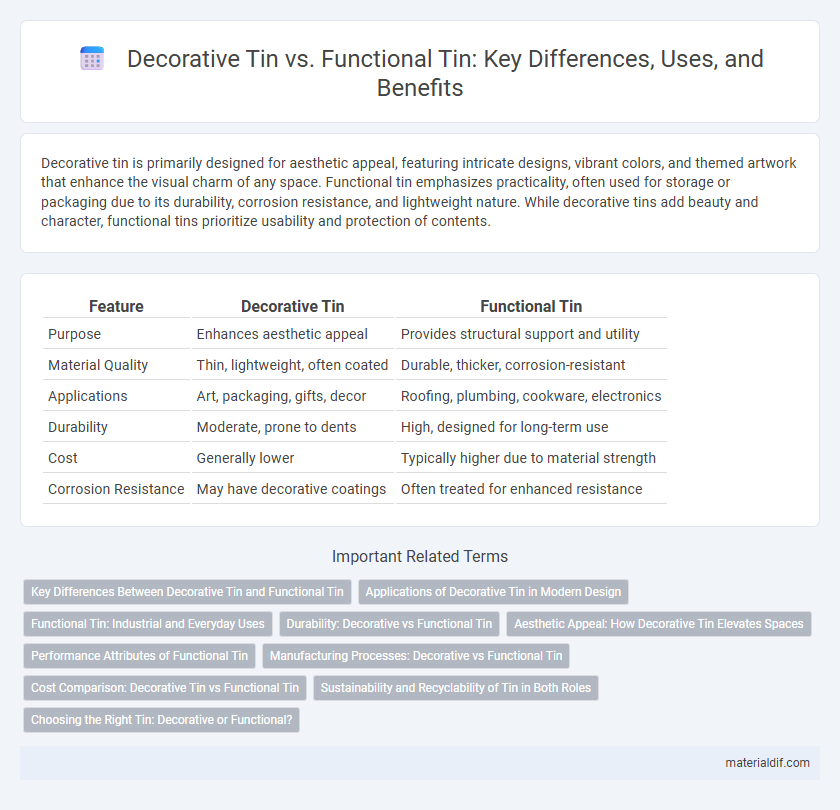

Decorative tin is primarily designed for aesthetic appeal, featuring intricate designs, vibrant colors, and themed artwork that enhance the visual charm of any space. Functional tin emphasizes practicality, often used for storage or packaging due to its durability, corrosion resistance, and lightweight nature. While decorative tins add beauty and character, functional tins prioritize usability and protection of contents.

Table of Comparison

| Feature | Decorative Tin | Functional Tin |

|---|---|---|

| Purpose | Enhances aesthetic appeal | Provides structural support and utility |

| Material Quality | Thin, lightweight, often coated | Durable, thicker, corrosion-resistant |

| Applications | Art, packaging, gifts, decor | Roofing, plumbing, cookware, electronics |

| Durability | Moderate, prone to dents | High, designed for long-term use |

| Cost | Generally lower | Typically higher due to material strength |

| Corrosion Resistance | May have decorative coatings | Often treated for enhanced resistance |

Key Differences Between Decorative Tin and Functional Tin

Decorative tin primarily serves aesthetic purposes, characterized by intricate designs, embossing, and vibrant finishes that enhance visual appeal. Functional tin, commonly used in packaging and industrial applications, emphasizes durability, corrosion resistance, and food-grade safety standards. Key differences include decorative tin's focus on appearance and ornamental value, while functional tin prioritizes performance, structural integrity, and protection.

Applications of Decorative Tin in Modern Design

Decorative tin is widely used in modern design for its aesthetic versatility and corrosion resistance, making it ideal for interior wall panels, ceiling tiles, and ornamental accents in homes and commercial spaces. Its malleability allows for intricate embossing and patterns, enhancing the visual appeal of furniture, lighting fixtures, and decorative art pieces. Unlike functional tin used primarily for packaging and industrial purposes, decorative tin emphasizes style and texture, contributing to contemporary and vintage-inspired architectural elements.

Functional Tin: Industrial and Everyday Uses

Functional tin plays a crucial role in industries such as electronics, where it is widely used for soldering components due to its excellent conductivity and corrosion resistance. In everyday applications, tin coatings protect steel from rust, extending the lifespan of containers and household items like food cans and plumbing fixtures. Its non-toxic properties and durability also make it essential in manufacturing batteries and various alloys used in mechanical parts.

Durability: Decorative vs Functional Tin

Decorative tin is often coated with protective finishes to enhance aesthetic appeal but tends to have lower resistance to corrosion and physical wear compared to functional tin. Functional tin, frequently used in industrial and food packaging applications, boasts higher durability due to its thicker layers and anti-corrosive properties, ensuring long-term protection against rust and environmental damage. The increased hardness and purity of functional tin alloys contribute to superior mechanical strength, making them ideal for applications requiring sustained performance.

Aesthetic Appeal: How Decorative Tin Elevates Spaces

Decorative tin enhances spaces through its intricate patterns and reflective surfaces that add depth and character to interiors, distinguishing it from the plain, utilitarian appearance of functional tin. Its malleable properties allow artisans to create embossed designs and vibrant finishes that elevate aesthetic appeal in home decor, architectural details, and furniture accents. The blend of durability and visual versatility makes decorative tin a preferred choice for adding vintage charm and elegance while maintaining the material's inherent rust resistance.

Performance Attributes of Functional Tin

Functional tin excels in corrosion resistance, providing durable protection for metal surfaces in industrial applications. Its excellent solderability and electrical conductivity make it indispensable in electronics manufacturing. Unlike decorative tin, functional tin prioritizes mechanical strength and thermal stability to enhance performance under demanding conditions.

Manufacturing Processes: Decorative vs Functional Tin

Decorative tin undergoes processes such as embossing, plating, or enamel coating to enhance its aesthetic appeal and provide corrosion resistance while maintaining malleability. Functional tin, commonly used in soldering or coatings, is refined through electroplating, casting, or alloying to achieve high purity and specific mechanical properties like hardness and melting point. Manufacturing decorative tin involves intricate surface treatments, whereas functional tin production prioritizes chemical composition and durability for industrial applications.

Cost Comparison: Decorative Tin vs Functional Tin

Decorative tin typically costs more than functional tin due to its intricate designs, coatings, and aesthetic finishes that require additional manufacturing processes. Functional tin, designed primarily for practical uses such as food packaging or corrosion resistance, is produced in large volumes with minimal decorative elements, resulting in lower costs. The price differential reflects the balance between visual appeal in decorative tin and utility-focused efficiency in functional tin.

Sustainability and Recyclability of Tin in Both Roles

Decorative tin, often used in art and packaging, is highly recyclable due to its pure composition and minimal contamination, promoting sustainability through repeated reuse. Functional tin, found in solder, plating, and alloys, enhances product longevity and corrosion resistance while also supporting circular economy principles by reclaiming tin during recycling processes. Both uses contribute to reducing environmental impact by enabling efficient tin recovery and minimizing the need for virgin material extraction.

Choosing the Right Tin: Decorative or Functional?

Choosing the right tin depends on its intended use; decorative tins emphasize aesthetic appeal with intricate designs and vibrant colors suited for gifting or display, while functional tins prioritize durability and protection, often used for food storage or industrial purposes. Material quality and sealing mechanisms are critical factors for functional tins to ensure freshness and prevent contamination. Decorative tins may feature coatings and finishes that enhance visual appeal but may lack the airtight features necessary for practical storage.

Decorative Tin vs Functional Tin Infographic

materialdif.com

materialdif.com