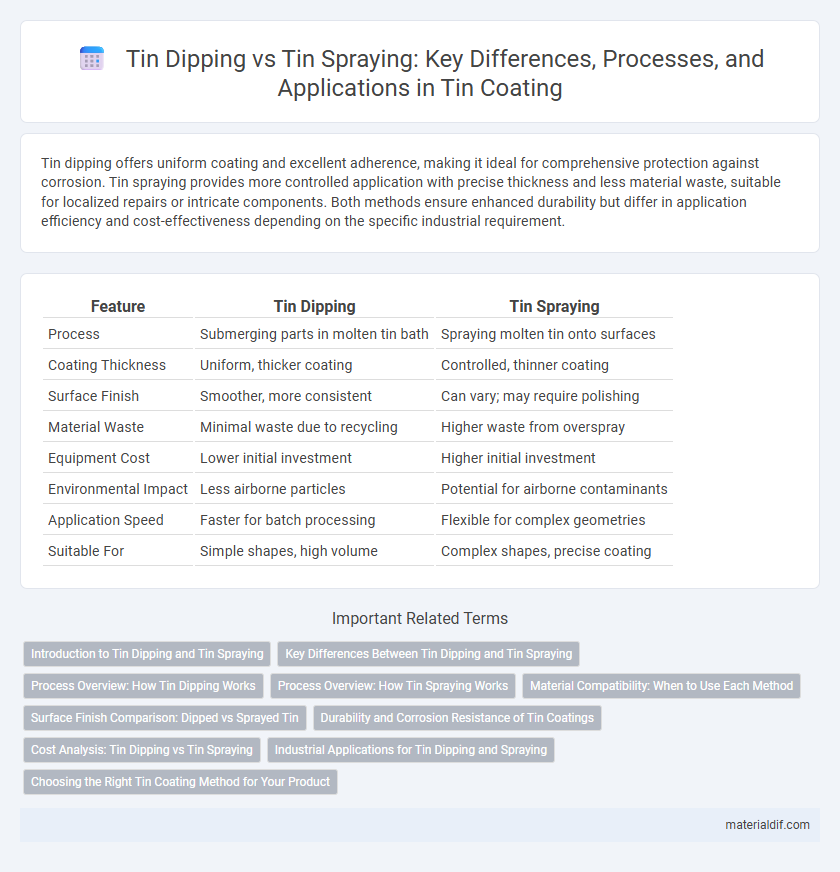

Tin dipping offers uniform coating and excellent adherence, making it ideal for comprehensive protection against corrosion. Tin spraying provides more controlled application with precise thickness and less material waste, suitable for localized repairs or intricate components. Both methods ensure enhanced durability but differ in application efficiency and cost-effectiveness depending on the specific industrial requirement.

Table of Comparison

| Feature | Tin Dipping | Tin Spraying |

|---|---|---|

| Process | Submerging parts in molten tin bath | Spraying molten tin onto surfaces |

| Coating Thickness | Uniform, thicker coating | Controlled, thinner coating |

| Surface Finish | Smoother, more consistent | Can vary; may require polishing |

| Material Waste | Minimal waste due to recycling | Higher waste from overspray |

| Equipment Cost | Lower initial investment | Higher initial investment |

| Environmental Impact | Less airborne particles | Potential for airborne contaminants |

| Application Speed | Faster for batch processing | Flexible for complex geometries |

| Suitable For | Simple shapes, high volume | Complex shapes, precise coating |

Introduction to Tin Dipping and Tin Spraying

Tin dipping involves immersing a metal substrate into molten tin to create a uniform, corrosion-resistant coating, enhancing solderability and electrical conductivity. Tin spraying, on the other hand, applies molten or powdered tin onto a surface using thermal spray techniques, allowing for targeted and controlled coatings on complex shapes. Both methods improve surface protection but differ in application precision, thickness control, and suitability for various industrial components.

Key Differences Between Tin Dipping and Tin Spraying

Tin dipping involves submerging metal components into molten tin, creating a uniform, fully coated surface ideal for corrosion resistance. Tin spraying applies molten tin by spraying it onto the substrate, allowing for selective coating and faster production cycles but with potentially less uniform thickness. The choice depends on factors like coating thickness control, production speed, and component geometry.

Process Overview: How Tin Dipping Works

Tin dipping involves immersing the substrate into a molten tin bath, allowing a uniform metallic coating to form through metallurgical bonding and cooling. The process parameters such as temperature, immersion time, and bath composition are meticulously controlled to achieve optimal adhesion, surface quality, and thickness. This method provides consistent coverage on complex geometries, making it highly effective for corrosion resistance and solderability enhancements.

Process Overview: How Tin Spraying Works

Tin spraying involves the application of molten tin onto a surface using a high-velocity spray gun, which atomizes the tin into fine droplets that rapidly solidify upon contact. This process allows for uniform coating thickness and excellent adhesion, making it suitable for complex geometries and large-scale production. Tin spraying provides a controlled environment to minimize oxidation, ensuring a high-quality, durable tin layer compared to traditional dipping methods.

Material Compatibility: When to Use Each Method

Tin dipping offers superior adhesion on complex geometries and is ideal for compatible metals like steel and copper, ensuring thorough coverage. Tin spraying is best suited for delicate or heat-sensitive substrates such as aluminum or electronic components, as it applies a controlled, thin layer without excessive heat exposure. Selecting between dipping and spraying depends on the substrate's material properties, thermal tolerance, and the required coating thickness.

Surface Finish Comparison: Dipped vs Sprayed Tin

Dipped tin coatings typically offer a thicker, more uniform layer that enhances corrosion resistance and provides a smoother surface finish compared to sprayed tin. Sprayed tin, while thinner and less uniform, allows for precise application in localized areas and results in a surface with slightly higher roughness, which may affect electrical conductivity. The choice between dipped and sprayed tin coatings depends on the specific surface finish requirements, with dipping favored for enhanced durability and spraying suited for targeted, controlled coating applications.

Durability and Corrosion Resistance of Tin Coatings

Tin dipping creates a thicker and more uniform coating compared to tin spraying, enhancing durability and providing superior corrosion resistance for metal surfaces. The molten bath used in tin dipping ensures better adhesion and coverage, significantly extending the lifespan of coated components in harsh environments. Tin spraying, while faster and more flexible for complex shapes, often results in thinner coatings that may be less effective against long-term corrosion.

Cost Analysis: Tin Dipping vs Tin Spraying

Tin dipping generally involves lower initial equipment costs and simpler maintenance compared to tin spraying, making it more cost-effective for large-scale, uniform coatings. Tin spraying requires higher upfront investment in advanced spray systems and specialized powders but allows for greater precision and reduced material waste, potentially lowering long-term operational expenses. Cost analysis must consider production volume, coating complexity, and application speed to determine the most economical approach between tin dipping and tin spraying.

Industrial Applications for Tin Dipping and Spraying

Tin dipping provides a uniform, corrosion-resistant coating ideal for electronic components and automotive parts requiring enhanced conductivity and durability. Tin spraying enables precise, localized application on large or irregular surfaces, commonly used in aerospace and heavy machinery for wear resistance. Both methods support industrial needs by improving metal performance but differ in application scale and coating precision.

Choosing the Right Tin Coating Method for Your Product

Selecting the ideal tin coating method depends on factors like product shape, desired thickness, and application environment. Tin dipping offers uniform coverage and excellent corrosion resistance, making it suitable for complex shapes and thicker coatings. Tin spraying provides precise control, is cost-effective for thin layers, and excels in repairing or enhancing existing coatings on flat or large surfaces.

Tin Dipping vs Tin Spraying Infographic

materialdif.com

materialdif.com