Eutectic solder melts at a single, precise temperature, ensuring a smooth and reliable joint ideal for delicate electronics and tin pet applications. Non-eutectic solder, with a melting range instead of a point, can cause partial melting and uneven bonding, which may compromise the integrity of the tin pet assembly. Choosing eutectic solder enhances the quality and durability of tin pet products by providing consistent melting behavior and strong adhesion.

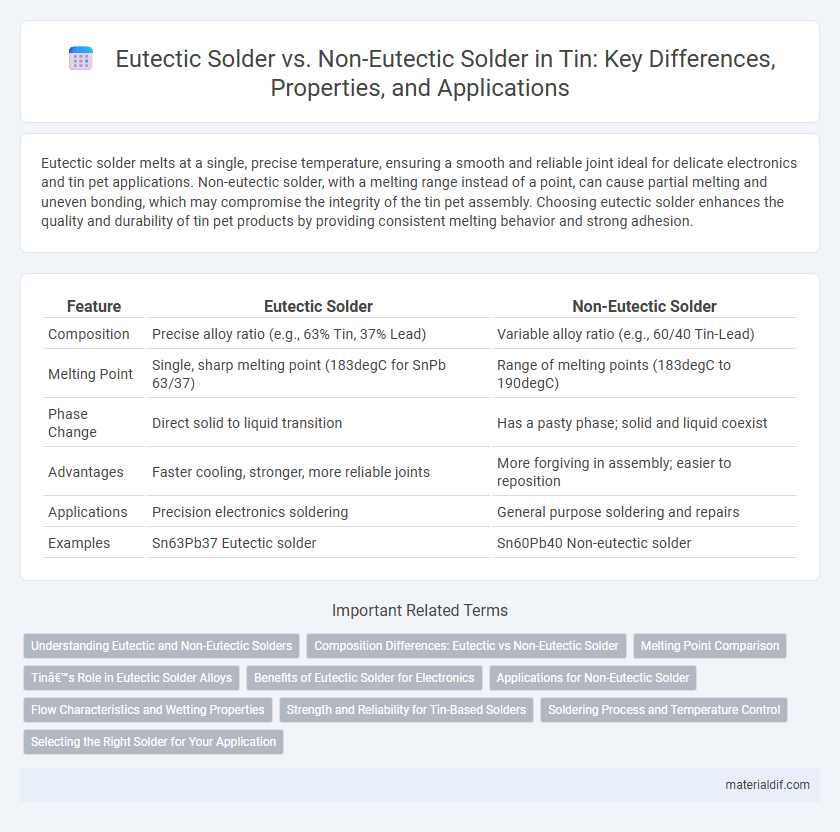

Table of Comparison

| Feature | Eutectic Solder | Non-Eutectic Solder |

|---|---|---|

| Composition | Precise alloy ratio (e.g., 63% Tin, 37% Lead) | Variable alloy ratio (e.g., 60/40 Tin-Lead) |

| Melting Point | Single, sharp melting point (183degC for SnPb 63/37) | Range of melting points (183degC to 190degC) |

| Phase Change | Direct solid to liquid transition | Has a pasty phase; solid and liquid coexist |

| Advantages | Faster cooling, stronger, more reliable joints | More forgiving in assembly; easier to reposition |

| Applications | Precision electronics soldering | General purpose soldering and repairs |

| Examples | Sn63Pb37 Eutectic solder | Sn60Pb40 Non-eutectic solder |

Understanding Eutectic and Non-Eutectic Solders

Eutectic solder, consisting primarily of a precise 63% tin and 37% lead composition, melts at a single temperature of 183degC, ensuring a sharp and reliable solid-to-liquid transition essential for consistent soldering quality. Non-eutectic solders feature varied tin-lead ratios, resulting in a melting range rather than a fixed point, which can cause a pasty phase and less predictable solidification during cooling. Understanding these differences is critical for selecting the appropriate solder type in electronics manufacturing to balance melting behavior, mechanical strength, and thermal performance.

Composition Differences: Eutectic vs Non-Eutectic Solder

Eutectic solder typically consists of a precise 63% tin and 37% lead composition, which solidifies at a single temperature of 183degC, ensuring a uniform melting point. Non-eutectic solder contains varying ratios of tin and lead, such as 60/40 or 50/50, resulting in a melting range rather than a crisp melting point. These composition differences influence soldering performance, with eutectic solder providing cleaner, more reliable joints due to its sharp phase transition.

Melting Point Comparison

Eutectic solder, composed typically of 63% tin and 37% lead, melts sharply at a single temperature of 183degC, providing a distinct melting point. Non-eutectic solder alloys, with varying tin-to-lead ratios, exhibit a melting range between 183degC and 215degC, rather than a fixed point. This melting point consistency enhances eutectic solder's precision in electronic soldering applications, reducing risks of cold joints.

Tin’s Role in Eutectic Solder Alloys

Tin is a critical component in eutectic solder alloys, typically combined with lead in a 63/37 ratio, which melts at a precise temperature of 183degC, ensuring a sharp and reliable melting point ideal for electronic soldering. Its contribution enhances the alloy's fluidity and wetting properties, leading to strong, consistent joints with minimal thermal stress during cooling. In non-eutectic solders, varying tin proportions lead to a broader melting range and less predictable solidification, which can compromise joint reliability and mechanical performance.

Benefits of Eutectic Solder for Electronics

Eutectic solder, typically composed of 63% tin and 37% lead, offers precise melting at 183degC, ensuring faster, uniform heating and reducing thermal stress on electronic components. This precise melting point minimizes defects such as cold joints and improves joint reliability, crucial for high-density circuit boards. The self-contained melting behavior of eutectic solder enhances workability and reduces the risk of solder bridging, leading to higher quality, long-lasting electronic assemblies.

Applications for Non-Eutectic Solder

Non-eutectic solder is commonly used in applications requiring gradual solidification to reduce thermal stress during cooling, such as in electronic component assembly and circuit board manufacturing. Its ability to melt over a temperature range rather than at a fixed point makes it suitable for creating strong mechanical bonds in multi-layered or complex solder joints. Non-eutectic solder is also preferred in repair work where controlled heat application is necessary to prevent damage to sensitive components.

Flow Characteristics and Wetting Properties

Eutectic solder, typically composed of a precise 63% tin and 37% lead alloy, offers superior flow characteristics, melting sharply at 183degC, which ensures uniform wetting and consistent joint formation. Non-eutectic solders have a broader melting range and exhibit slower flow with potential for partial melting, resulting in uneven wetting and weaker mechanical bonds. The excellent wetting properties of eutectic tin-based solder improve electrical conductivity and reliability in printed circuit board (PCB) assemblies compared to the variable performance of non-eutectic alternatives.

Strength and Reliability for Tin-Based Solders

Eutectic tin-based solder, typically a 63/37 tin-lead alloy, offers superior strength and reliability due to its uniform melting point, ensuring consistent joint formation without partial melting. Non-eutectic solders, such as 60/40 alloys, have a melting range that can cause uneven cooling and weaker microstructures, leading to reduced mechanical strength and potential reliability issues under thermal stress. The homogenous microstructure of eutectic solder joints enhances durability and resistance to fatigue in electronic assembly applications.

Soldering Process and Temperature Control

Eutectic solder, typically composed of 63% tin and 37% lead, melts at a precise temperature of 183degC, ensuring a single-phase transition that facilitates controlled and consistent soldering processes. Non-eutectic solder alloys, with varying tin and lead ratios, exhibit a temperature range during melting, creating a mushy phase that requires precise temperature management to avoid defects such as cold joints or incomplete wetting. Effective temperature control during soldering is critical for both solder types but is especially essential for non-eutectic solders to maintain joint integrity and optimize thermal cycles in electronic manufacturing.

Selecting the Right Solder for Your Application

Eutectic solder, with a precise melting point of 183degC, ensures a smooth transition from solid to liquid, making it ideal for applications requiring minimal thermal stress and clean joint formation. Non-eutectic solder melts over a temperature range, offering flexibility for repairs and complex assemblies but may cause increased thermal cycling and potential joint fatigue. Selecting the right solder depends on factors such as operating temperature, mechanical stress tolerance, and the need for reliable electrical conductivity in your specific application.

Eutectic Solder vs Non-Eutectic Solder Infographic

materialdif.com

materialdif.com