Soldering and brazing are two common techniques used to join tin pet components, differing primarily in temperature and filler materials. Soldering operates at lower temperatures, typically below 450degF, using a filler metal with a melting point below this threshold, which is ideal for delicate or heat-sensitive tin pet applications. Brazing involves higher temperatures, usually above 450degF, and produces stronger joints by melting a filler metal that flows into the joint via capillary action, suitable for more durable and high-stress tin pet assemblies.

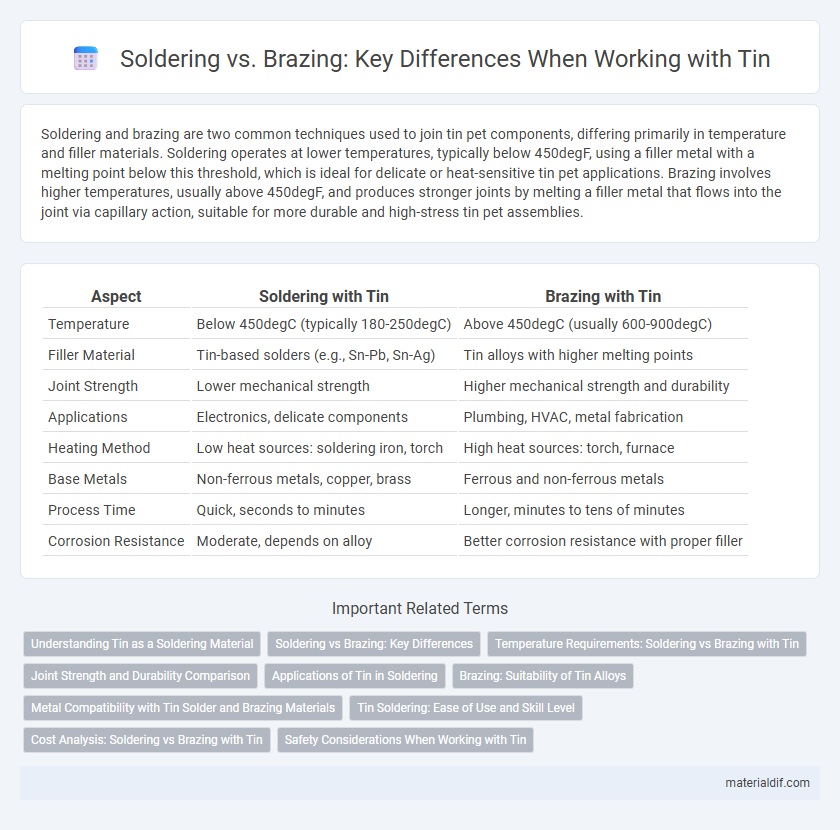

Table of Comparison

| Aspect | Soldering with Tin | Brazing with Tin |

|---|---|---|

| Temperature | Below 450degC (typically 180-250degC) | Above 450degC (usually 600-900degC) |

| Filler Material | Tin-based solders (e.g., Sn-Pb, Sn-Ag) | Tin alloys with higher melting points |

| Joint Strength | Lower mechanical strength | Higher mechanical strength and durability |

| Applications | Electronics, delicate components | Plumbing, HVAC, metal fabrication |

| Heating Method | Low heat sources: soldering iron, torch | High heat sources: torch, furnace |

| Base Metals | Non-ferrous metals, copper, brass | Ferrous and non-ferrous metals |

| Process Time | Quick, seconds to minutes | Longer, minutes to tens of minutes |

| Corrosion Resistance | Moderate, depends on alloy | Better corrosion resistance with proper filler |

Understanding Tin as a Soldering Material

Tin is a primary metal used in soldering due to its low melting point of approximately 232degC, which allows for easy joining of electronic components without damaging sensitive parts. Its excellent wettability and strong adhesion to copper and other metals enhance the reliability of solder joints in electrical circuits. Unlike brazing, which operates at higher temperatures above 450degC and involves filler metals like silver or brass, tin-based solder provides precise, low-temperature bonding crucial for delicate electronic assembly.

Soldering vs Brazing: Key Differences

Soldering involves joining metals using a filler metal with a melting point below 450degC, typically tin-based alloys, creating a strong electrical connection without melting the base metals. Brazing uses filler metals with melting points above 450degC, producing stronger joints suitable for structural applications while maintaining the integrity of the base metals. Tin solder offers excellent wetting properties and corrosion resistance, making it ideal for electronics, whereas brazing with silver or copper alloys provides enhanced mechanical strength for plumbing and HVAC systems.

Temperature Requirements: Soldering vs Brazing with Tin

Soldering with tin requires temperatures typically below 450degF (232degC), making it suitable for delicate electronics and fine metalwork. Brazing with tin alloys demands higher heat, usually above 450degF and up to around 600degF (315degC), allowing stronger joints for plumbing and industrial applications. Temperature control during soldering and brazing is critical to maintain the integrity of tin-based joints and prevent oxidation or damage to components.

Joint Strength and Durability Comparison

Soldering typically produces joints with lower strength, generally ranging from 15 to 50 MPa, making it suitable for delicate electronic components where minimal thermal impact is critical. Brazing, using higher temperatures and filler metals like bronze or silver alloys, can achieve joint strengths exceeding 350 MPa, providing superior mechanical durability for structural applications. The enhanced metallurgical bonding in brazed joints results in greater resistance to fatigue and corrosion, extending the lifespan of assemblies compared to soldered connections.

Applications of Tin in Soldering

Tin is a key component in soldering alloys due to its excellent wettability and low melting point, making it ideal for joining electronic components and delicate circuits. Common solder alloys, such as tin-lead and tin-silver-copper, provide reliable electrical conductivity and mechanical strength in printed circuit board (PCB) assembly. Its ability to form strong, corrosion-resistant bonds enables widespread use in consumer electronics, automotive wiring, and telecommunications equipment.

Brazing: Suitability of Tin Alloys

Tin alloys in brazing offer excellent wettability and corrosion resistance, making them ideal for joining dissimilar metals with minimal thermal distortion. Their low melting points, typically ranging between 450degC to 550degC, enable effective capillary action while preserving base metal integrity. Common tin-based brazing alloys, such as those combining tin with copper or silver, provide enhanced mechanical strength and electrical conductivity, crucial for precision assemblies.

Metal Compatibility with Tin Solder and Brazing Materials

Tin solder exhibits excellent compatibility with metals such as copper, brass, and nickel, forming strong, corrosion-resistant joints in electronic and plumbing applications. Brazing materials, often containing silver or copper alloys, offer superior strength and higher temperature resistance, making them suitable for joining dissimilar metals including stainless steel, steel, and cast iron. Selecting between tin solder and brazing alloys depends on the metals involved and the thermal and mechanical requirements of the joint.

Tin Soldering: Ease of Use and Skill Level

Tin soldering offers ease of use due to its lower melting point, typically around 183degC (361degF), which reduces the risk of damaging sensitive components during electronics assembly. The process requires minimal skill compared to brazing, as tin solder flows readily and solidifies quickly, allowing for precise and reliable joint formation. This makes tin soldering ideal for beginners and hobbyists working on circuit boards and delicate metal connections.

Cost Analysis: Soldering vs Brazing with Tin

Soldering with tin offers a cost-effective solution due to lower temperatures and minimal energy consumption compared to brazing, which requires higher heat and more expensive filler materials like silver or copper alloys. The overall material cost in soldering is typically reduced, as tin-based solders are widely available and less costly than brazing rods. Maintenance and operational expenses also favor soldering, making it a budget-friendly choice for delicate electronics and small-scale applications.

Safety Considerations When Working with Tin

Soldering with tin involves lower temperatures, typically below 450degF (232degC), reducing the risk of burns and toxic fumes compared to brazing, which requires higher temperatures above 800degF (427degC) and can release harmful flux fumes. Proper ventilation and the use of lead-free tin alloys minimize exposure to lead and other hazardous materials common in soldering. Protective gear such as heat-resistant gloves and safety glasses is essential in both soldering and brazing to prevent injuries from molten metal and hot surfaces.

Soldering vs Brazing Infographic

materialdif.com

materialdif.com