Hot-dipped tinning involves immersing metal in molten tin, creating a thick, durable coating that offers superior corrosion resistance and excellent solderability. Electroplated tinning applies a thinner, more uniform layer through an electrochemical process, ideal for precision electronics requiring fine surface finishes. Choosing between hot-dipped and electroplated tinning depends on the desired coating thickness, durability, and application requirements.

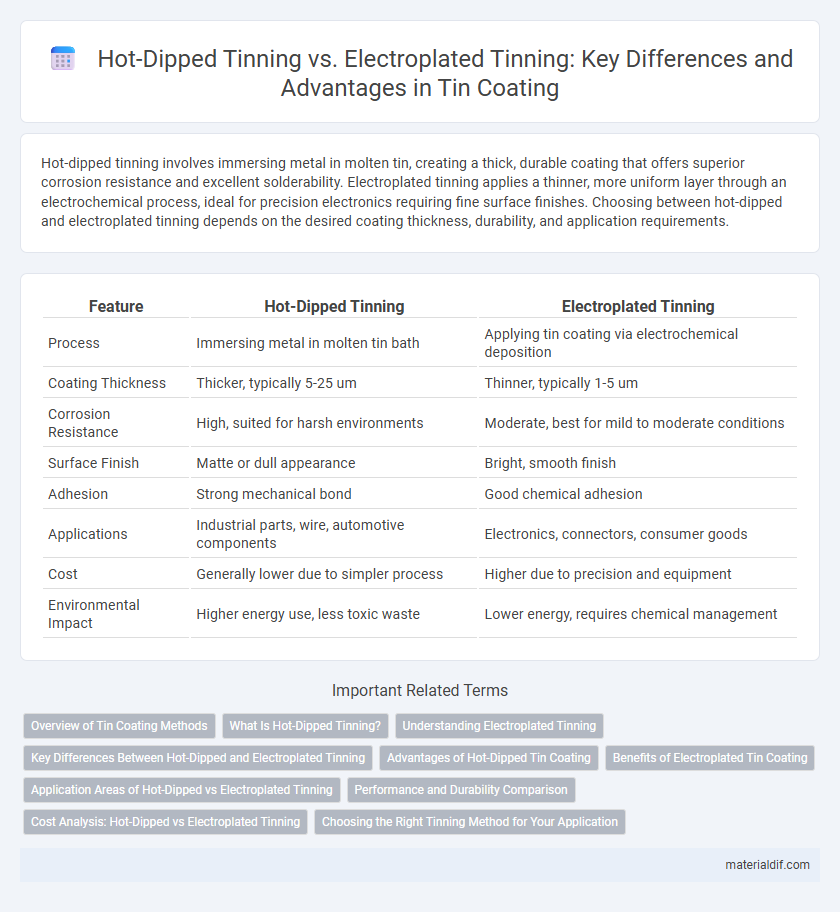

Table of Comparison

| Feature | Hot-Dipped Tinning | Electroplated Tinning |

|---|---|---|

| Process | Immersing metal in molten tin bath | Applying tin coating via electrochemical deposition |

| Coating Thickness | Thicker, typically 5-25 um | Thinner, typically 1-5 um |

| Corrosion Resistance | High, suited for harsh environments | Moderate, best for mild to moderate conditions |

| Surface Finish | Matte or dull appearance | Bright, smooth finish |

| Adhesion | Strong mechanical bond | Good chemical adhesion |

| Applications | Industrial parts, wire, automotive components | Electronics, connectors, consumer goods |

| Cost | Generally lower due to simpler process | Higher due to precision and equipment |

| Environmental Impact | Higher energy use, less toxic waste | Lower energy, requires chemical management |

Overview of Tin Coating Methods

Hot-dipped tinning involves immersing the metal substrate in molten tin, creating a thick, robust coating that offers excellent corrosion resistance and solderability, commonly used in heavy-duty applications. Electroplated tinning applies a thin, uniform layer of tin through an electrochemical process, ensuring precise control of coating thickness ideal for electronic components and delicate parts. Both methods enhance metal durability and prevent oxidation, with choice depending on factors like required coating thickness, application environment, and cost considerations.

What Is Hot-Dipped Tinning?

Hot-dipped tinning involves immersing a metal substrate into molten tin, creating a thick, durable coating that offers excellent corrosion resistance and strong adhesion. This process differs from electroplated tinning, which uses an electrical current to deposit a thinner layer of tin, resulting in less abrasion resistance. Hot-dipped tinning is commonly used in applications requiring robust protection against environmental stress and mechanical wear.

Understanding Electroplated Tinning

Electroplated tinning involves depositing a thin, uniform layer of tin onto a metal surface using an electrolytic process, ensuring excellent adhesion and corrosion resistance. This method allows precise control over coating thickness, enhancing electrical conductivity and solderability in electronic components. Compared to hot-dipped tinning, electroplating produces a smoother finish and better compatibility with delicate substrates typically used in electronics manufacturing.

Key Differences Between Hot-Dipped and Electroplated Tinning

Hot-dipped tinning involves immersing the metal in molten tin, creating a thicker, more durable coating that offers superior corrosion resistance and solderability. Electroplated tinning uses an electrical current to deposit a thin, uniform layer of tin, resulting in a smoother finish with precise thickness control ideal for delicate electronic components. Key differences include coating thickness, adhesion strength, corrosion protection, and application methods, with hot-dipped tinning providing enhanced durability while electroplated tinning ensures greater dimensional accuracy.

Advantages of Hot-Dipped Tin Coating

Hot-dipped tinning offers superior corrosion resistance due to its thicker and more uniform coating compared to electroplated tinning, enhancing the longevity of the protected material. The process provides excellent solderability and mechanical durability, making it ideal for applications exposed to harsh environments. Hot-dipped tin coatings exhibit better adherence and coverage on irregular surfaces, ensuring comprehensive protection against oxidation and wear.

Benefits of Electroplated Tin Coating

Electroplated tin coating offers superior uniformity and precise thickness control compared to hot-dipped tinning, resulting in enhanced corrosion resistance and improved solderability for electronic components. This method minimizes surface defects and provides better adhesion, which is critical for high-reliability applications in electronics and automotive industries. The ability to tailor the plating process ensures consistent coverage on complex geometries, optimizing performance and durability.

Application Areas of Hot-Dipped vs Electroplated Tinning

Hot-dipped tinning is widely applied in corrosion-resistant coatings for steel pipes, cookware, and automotive parts due to its thicker, more durable tin layer. Electroplated tinning is preferred for electronic components, connectors, and precision parts where a thinner, uniform coating enhances electrical conductivity. Industrial sectors such as construction and electronics benefit from selecting hot-dipped or electroplated tinning based on durability requirements and surface finish needs.

Performance and Durability Comparison

Hot-dipped tinning creates a thicker, more robust coating by immersing the substrate in molten tin, offering superior corrosion resistance and durability in harsh environments. Electroplated tinning produces a thinner, more uniform layer through an electrolytic process, enhancing conductivity but providing less protection against mechanical wear and corrosion. For applications requiring long-term performance under abrasive or corrosive conditions, hot-dipped tinning is generally more durable, while electroplated tinning suits precision electronics needing fine surface finishes.

Cost Analysis: Hot-Dipped vs Electroplated Tinning

Hot-dipped tinning incurs higher initial equipment and energy costs due to molten metal baths but offers superior corrosion resistance and thicker coatings that reduce long-term maintenance expenses. Electroplated tinning involves lower upfront costs and precise coating control, making it cost-effective for thin, uniform layers in electronics and delicate components. Evaluating total cost of ownership, hot-dipped tinning benefits heavy-duty industrial applications while electroplating suits budget-conscious projects requiring fine surface finishes.

Choosing the Right Tinning Method for Your Application

Hot-dipped tinning creates a thick, corrosion-resistant coating by immersing components in molten tin, making it ideal for applications requiring robust protection against oxidation and wear. Electroplated tinning deposits a thin, uniform layer of tin through electrochemical processes, offering precision and superior electrical conductivity suited for delicate electronic parts. Selecting the right tinning method depends on factors like desired coating thickness, environmental exposure, cost considerations, and specific performance requirements of the application.

Hot-dipped tinning vs Electroplated tinning Infographic

materialdif.com

materialdif.com