Tin lithography offers superior detail and durability for tin pet labels, making it ideal for high-quality, long-lasting designs. Digital printing provides greater flexibility and faster turnaround times, allowing for easy customization and smaller production runs. Choosing between tin lithography and digital printing depends on the project's complexity, budget, and volume requirements.

Table of Comparison

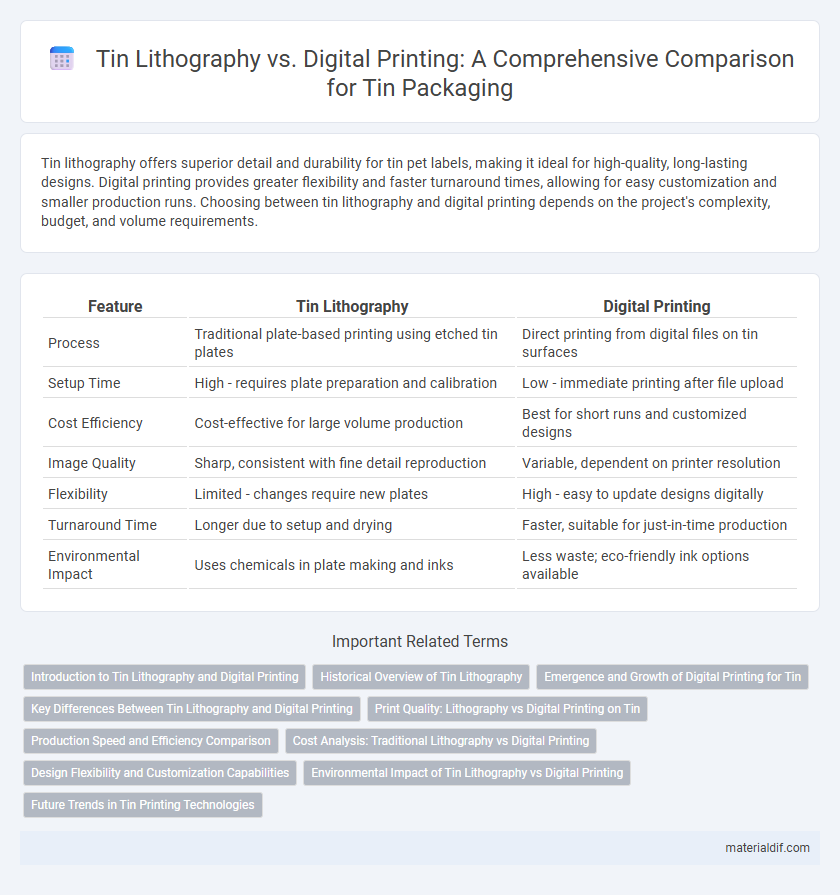

| Feature | Tin Lithography | Digital Printing |

|---|---|---|

| Process | Traditional plate-based printing using etched tin plates | Direct printing from digital files on tin surfaces |

| Setup Time | High - requires plate preparation and calibration | Low - immediate printing after file upload |

| Cost Efficiency | Cost-effective for large volume production | Best for short runs and customized designs |

| Image Quality | Sharp, consistent with fine detail reproduction | Variable, dependent on printer resolution |

| Flexibility | Limited - changes require new plates | High - easy to update designs digitally |

| Turnaround Time | Longer due to setup and drying | Faster, suitable for just-in-time production |

| Environmental Impact | Uses chemicals in plate making and inks | Less waste; eco-friendly ink options available |

Introduction to Tin Lithography and Digital Printing

Tin lithography is a traditional printing method utilizing etched tin plates to transfer images onto surfaces, known for its durability and high-quality detail. Digital printing, by contrast, employs digital files to directly produce images on various materials, offering faster turnaround and greater design flexibility. Both techniques serve distinct purposes depending on project scale and precision requirements.

Historical Overview of Tin Lithography

Tin lithography originated in the early 19th century as a revolutionary printing technique utilizing tin plates to produce detailed images with high durability. This method dominated industrial printing due to its ability to create fine lines and rich textures, playing a significant role in map-making, packaging, and artistic prints. Despite being largely replaced by digital printing in the late 20th century, tin lithography remains valued for its historical craftsmanship and unique tactile quality.

Emergence and Growth of Digital Printing for Tin

Digital printing for tin surfaces has surged due to advancements in high-resolution inkjet technology and UV-curable inks, allowing vibrant, durable graphics on metal substrates. The emergence of digital printing offers rapid turnaround times, customizable designs, and reduced setup costs compared to traditional tin lithography. Growth in industries such as packaging and promotional products drives adoption, leveraging digital printing's flexibility to meet evolving market demands.

Key Differences Between Tin Lithography and Digital Printing

Tin lithography relies on traditional metal plates and chemical processes to transfer images, ensuring high durability and consistent print quality ideal for large print runs. Digital printing bypasses plates, using direct digital files to produce prints quickly and flexibly, making it more cost-effective for short runs and variable data printing. The key difference lies in tin lithography's efficiency for mass production with superior color fidelity, while digital printing excels in speed, customization, and minimal setup requirements.

Print Quality: Lithography vs Digital Printing on Tin

Lithography on tin offers superior print quality with precise color registration and sharp details, ideal for high-volume production of metal packaging requiring durability and vibrant finishes. Digital printing on tin enables quick customization and short runs, delivering decent print clarity but may lack the consistent sharpness and color depth found in lithographic prints. The choice between lithography and digital printing on tin largely depends on the balance between quality demands and production flexibility.

Production Speed and Efficiency Comparison

Tin lithography offers high production speed and efficiency due to its established plate-making process and rapid ink transfer, making it suitable for large-volume runs. Digital printing, while slower in setup for large quantities, provides faster turnaround times for short runs and allows for on-demand printing with minimal waste. The efficiency of tin lithography excels in mass production, whereas digital printing offers flexibility and speed for customized, small-batch tin printing projects.

Cost Analysis: Traditional Lithography vs Digital Printing

The cost analysis of tin lithography versus digital printing reveals significant differences based on production volume and setup expenses. Tin lithography incurs higher initial costs due to plate creation and setup but becomes more economical for large print runs because of its lower per-unit expense. Digital printing eliminates setup fees, making it cost-effective for small batches or customized prints on tin surfaces, though the per-unit cost remains higher compared to traditional lithography.

Design Flexibility and Customization Capabilities

Tin lithography offers limited design flexibility due to fixed chemical plates, making it ideal for large runs of consistent designs but less adaptable to frequent changes. Digital printing on tin excels in customization capabilities, allowing for variable data, intricate details, and quick adjustments without the need for plate changes. This technology enables personalized and short-run prints with high-resolution graphics, meeting dynamic market demands more efficiently than traditional lithography.

Environmental Impact of Tin Lithography vs Digital Printing

Tin lithography involves traditional chemical processes that generate hazardous waste and consume significant water and energy, contributing to environmental pollution. Digital printing minimizes the use of chemicals and reduces waste by enabling precise ink application and on-demand production, resulting in a lower carbon footprint. Compared to tin lithography, digital printing supports eco-friendly practices by cutting resource consumption and decreasing toxic emissions during the printing process.

Future Trends in Tin Printing Technologies

Tin lithography is expected to evolve with the integration of advanced laser engraving and micro-etching techniques, enhancing precision and reducing waste in tinplate printing. Digital printing on tin offers rapid customization, color vibrancy, and shorter production cycles, driving its adoption in limited edition packaging and smart labeling with embedded QR codes. Future trends indicate a hybrid approach combining lithography's durability with digital printing's flexibility to optimize cost-efficiency and environmental sustainability in tin product decoration.

Tin lithography vs Digital printing Infographic

materialdif.com

materialdif.com