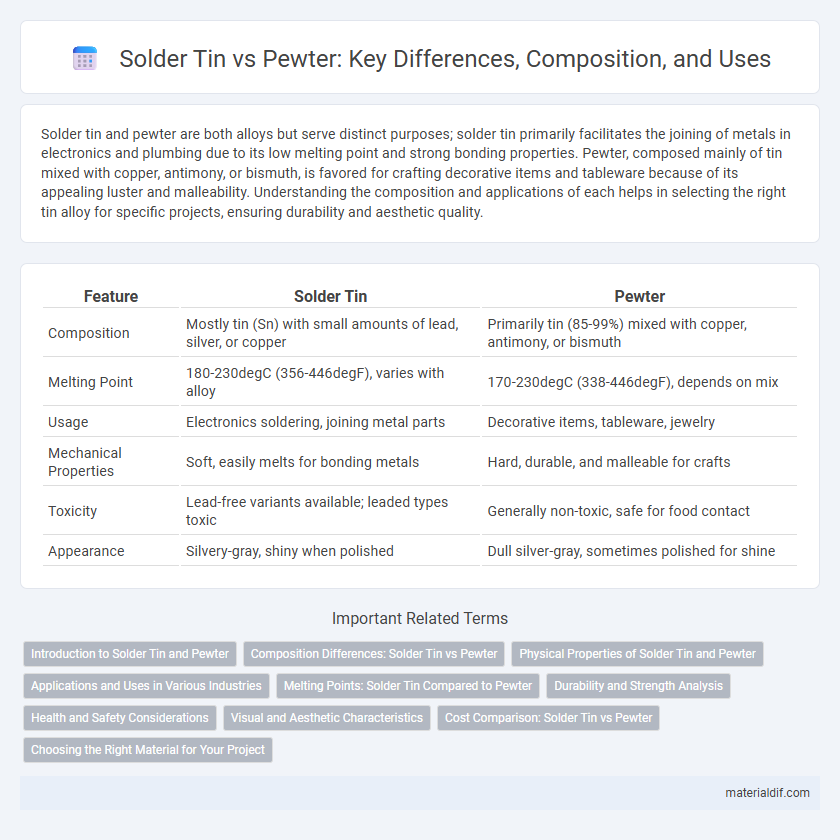

Solder tin and pewter are both alloys but serve distinct purposes; solder tin primarily facilitates the joining of metals in electronics and plumbing due to its low melting point and strong bonding properties. Pewter, composed mainly of tin mixed with copper, antimony, or bismuth, is favored for crafting decorative items and tableware because of its appealing luster and malleability. Understanding the composition and applications of each helps in selecting the right tin alloy for specific projects, ensuring durability and aesthetic quality.

Table of Comparison

| Feature | Solder Tin | Pewter |

|---|---|---|

| Composition | Mostly tin (Sn) with small amounts of lead, silver, or copper | Primarily tin (85-99%) mixed with copper, antimony, or bismuth |

| Melting Point | 180-230degC (356-446degF), varies with alloy | 170-230degC (338-446degF), depends on mix |

| Usage | Electronics soldering, joining metal parts | Decorative items, tableware, jewelry |

| Mechanical Properties | Soft, easily melts for bonding metals | Hard, durable, and malleable for crafts |

| Toxicity | Lead-free variants available; leaded types toxic | Generally non-toxic, safe for food contact |

| Appearance | Silvery-gray, shiny when polished | Dull silver-gray, sometimes polished for shine |

Introduction to Solder Tin and Pewter

Solder tin is a metal alloy primarily composed of tin and lead or other metals, designed to create strong, conductive joints in electrical and plumbing applications. Pewter, on the other hand, is a malleable metal alloy mostly consisting of tin combined with copper, antimony, or bismuth, traditionally used for decorative objects and tableware. The key distinction lies in solder tin's purpose for bonding metals with a low melting point, while pewter emphasizes durability and aesthetic appeal.

Composition Differences: Solder Tin vs Pewter

Solder tin primarily consists of a blend of tin and lead or a lead-free alloy such as tin-copper or tin-silver-copper, formulated for melting at lower temperatures to create strong, conductive joints. Pewter is an alloy predominantly made of tin mixed with small amounts of copper, antimony, and sometimes bismuth or silver, designed for its malleability and lustrous finish rather than electrical conductivity. The key compositional difference lies in solder tin's emphasis on melting point and joint strength for electronics, while pewter's blend targets decorative applications and durability.

Physical Properties of Solder Tin and Pewter

Solder tin exhibits a melting point around 232degC, making it ideal for joining metal parts with precision and durability due to its excellent thermal and electrical conductivity. Pewter typically melts between 170degC and 230degC, depending on its alloy composition, featuring a lower melting point but greater malleability and a distinct, dull silver-gray appearance. The physical properties of solder tin emphasize hardness and resistance to oxidation, whereas pewter prioritizes ease of casting and shaping with a softer, more pliable structure.

Applications and Uses in Various Industries

Solder tin, an alloy primarily consisting of tin and lead or tin and silver, is widely used in the electronics industry for joining electrical components due to its excellent conductivity and melting properties. Pewter, composed mainly of tin mixed with copper, antimony, or bismuth, is favored in the manufacturing of decorative items, kitchenware, and collectibles because of its malleability and low melting point. The distinction in alloy composition makes solder tin ideal for precision electronic soldering, while pewter serves aesthetic and functional roles in household and artisanal metalwork.

Melting Points: Solder Tin Compared to Pewter

Solder tin typically melts between 217degC and 221degC, making it suitable for electronic and metal joining applications requiring precise melting control. Pewter, predominantly composed of tin with small amounts of copper, antimony, or bismuth, melts at a higher range of approximately 170degC to 230degC depending on alloy composition, offering greater malleability and decorative uses. The specific melting points influence their selection, with solder tin preferred for reliable, low-temperature fusing in electronics and pewter favored for casting and artistic items due to its versatile melting behavior.

Durability and Strength Analysis

Solder tin, typically composed of a blend of tin and lead or other metals, offers superior mechanical strength and electrical conductivity, making it ideal for creating durable, long-lasting electronic joints. Pewter, an alloy primarily made of tin combined with copper, antimony, or bismuth, provides moderate strength but excels in malleability and corrosion resistance rather than supporting heavy mechanical stress. In applications requiring robust durability and tensile strength, solder tin outperforms pewter, which is better suited for decorative or lightweight functional uses due to its lower structural resilience.

Health and Safety Considerations

Solder tin primarily contains a lead-free alloy such as tin-copper or tin-silver-copper, reducing exposure to toxic lead, making it safer for electronic soldering applications. Pewter, traditionally composed of tin mixed with antimony, copper, and sometimes lead, poses health risks if it contains lead and is used in food-related items due to potential lead leaching. Proper ventilation and avoiding ingestion are critical safety considerations with both materials to minimize exposure to fumes and potential heavy metals.

Visual and Aesthetic Characteristics

Solder tin typically exhibits a shiny, silvery-gray appearance with a smooth, metallic finish that enhances the precision of electronic connections. Pewter, primarily composed of tin combined with copper and antimony, features a softer, matte gray surface with a slight bluish or warm hue that creates a vintage or rustic look in decorative items. The visual contrast between solder tin's bright sheen and pewter's muted luster makes each suitable for distinct applications emphasizing either functionality or artisanal appeal.

Cost Comparison: Solder Tin vs Pewter

Solder tin is generally more cost-effective than pewter due to its primary use in electronics requiring high purity and low melting point alloys, which reduces manufacturing expenses. Pewter, composed mainly of tin mixed with copper, antimony, or bismuth, often incurs higher costs because of its decorative applications and additional alloying elements. The price difference reflects the material composition, with solder tin optimized for functional efficiency and pewter designed for aesthetic appeal.

Choosing the Right Material for Your Project

Solder tin, mainly composed of tin and lead or tin and silver, offers excellent electrical conductivity and low melting points, ideal for electronic connections and precise soldering tasks. Pewter, an alloy primarily of tin with copper, antimony, and sometimes bismuth, provides a durable, corrosion-resistant material suited for decorative items, jewelry, and cookware. Selecting the right material depends on the project's requirements for strength, conductivity, melting temperature, and aesthetic appeal.

Solder Tin vs Pewter Infographic

materialdif.com

materialdif.com