Tin pet exhibits a unique balance between malleability and hardness, making it ideal for intricate shaping while maintaining structural integrity. Its malleability allows for easy bending and molding without cracking, whereas its moderate hardness provides sufficient resistance to deformation under stress. This combination ensures tin pet components are both durable and adaptable for various manufacturing applications.

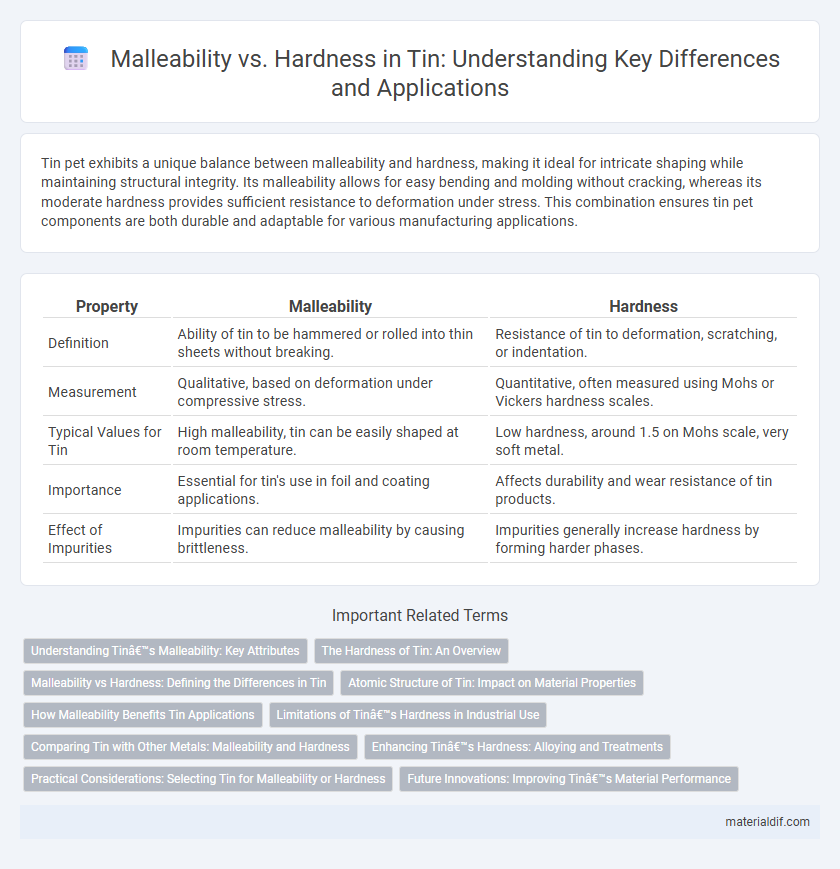

Table of Comparison

| Property | Malleability | Hardness |

|---|---|---|

| Definition | Ability of tin to be hammered or rolled into thin sheets without breaking. | Resistance of tin to deformation, scratching, or indentation. |

| Measurement | Qualitative, based on deformation under compressive stress. | Quantitative, often measured using Mohs or Vickers hardness scales. |

| Typical Values for Tin | High malleability, tin can be easily shaped at room temperature. | Low hardness, around 1.5 on Mohs scale, very soft metal. |

| Importance | Essential for tin's use in foil and coating applications. | Affects durability and wear resistance of tin products. |

| Effect of Impurities | Impurities can reduce malleability by causing brittleness. | Impurities generally increase hardness by forming harder phases. |

Understanding Tin’s Malleability: Key Attributes

Tin exhibits exceptional malleability, allowing it to be easily shaped and deformed without cracking, which is vital for applications requiring thin sheets or intricate designs. Its relatively low hardness, measured on the Mohs scale around 1.5, enables this flexibility but limits its use in high-wear environments. Understanding tin's balance of softness and ductility is crucial for optimizing its performance in electronics, coatings, and soldering materials.

The Hardness of Tin: An Overview

Tin exhibits moderate hardness, typically rated around 1.5 on the Mohs scale, making it softer than many metals like steel and copper but harder than lead. Its crystalline structure allows tin to maintain a balance between durability and malleability, enabling it to resist deformation under mild stress while still being easy to shape. This unique hardness characteristic makes tin ideal for applications such as coating other metals to prevent corrosion and in soldering alloys where controlled softness is essential.

Malleability vs Hardness: Defining the Differences in Tin

Tin exhibits exceptional malleability, allowing it to be easily hammered or rolled into thin sheets without breaking, which contrasts with its moderate hardness that provides sufficient resistance to scratching and deformation. The balance between tin's softness and strength is critical in applications like soldering and plating, where malleability ensures formability while hardness maintains durability. Understanding tin's unique combination of high malleability and moderate hardness underpins its versatility in industrial and manufacturing processes.

Atomic Structure of Tin: Impact on Material Properties

Tin's atomic structure, characterized by a tetragonal crystal system in its most stable beta phase, directly influences its malleability and hardness. The arrangement of tin atoms allows layers to slide past each other easily, enhancing malleability, while relatively weak metallic bonds account for its low hardness. This atomic configuration makes tin ideal for applications requiring flexibility without significant deformation or brittleness.

How Malleability Benefits Tin Applications

Tin's high malleability allows it to be easily shaped into thin sheets and intricate forms without cracking, making it ideal for applications like soldering and coating. This flexibility enables tin to create durable, corrosion-resistant layers on other metals, enhancing their longevity and performance. The balance between malleability and sufficient hardness ensures tin components maintain structural integrity while adapting to various industrial uses.

Limitations of Tin’s Hardness in Industrial Use

Tin exhibits notable malleability, allowing it to be easily shaped and formed, but its limited hardness restricts its direct application in industrial components subject to high stress or abrasion. The softness of tin results in poor wear resistance and vulnerability to deformation under mechanical loads, necessitating alloying or protective coatings to enhance durability. These limitations confine pure tin's use primarily to protective coatings, soldering, or low-stress roles rather than structural or high-wear industrial parts.

Comparing Tin with Other Metals: Malleability and Hardness

Tin exhibits high malleability, allowing it to be easily shaped and hammered without breaking, which contrasts with metals like iron that are harder but less malleable. Its Mohs hardness of about 1.5 makes it much softer than metals such as steel, which ranges from 4 to 4.5, enabling tin to deform under low pressure while steel resists scratching and denting. Compared to aluminum, tin is less hard but similarly malleable, making it ideal for applications needing flexible yet soft metals.

Enhancing Tin’s Hardness: Alloying and Treatments

Enhancing tin's hardness involves alloying with elements such as copper, antimony, and silver, which significantly improve its mechanical strength and wear resistance. Heat treatments like annealing and cold working further refine the microstructure, increasing hardness while maintaining some malleability. These methods balance tin's inherent softness with enhanced durability for industrial applications.

Practical Considerations: Selecting Tin for Malleability or Hardness

Selecting tin for malleability involves prioritizing applications like plating or soldering where flexibility and ease of deformation are critical, as its low hardness allows it to bend without breaking. For hardness, tin alloys such as bronze or pewter are preferred, offering enhanced strength and wear resistance suitable for structural components or decorative items requiring durability. Practical considerations hinge on the intended use, balancing tin's intrinsic softness against alloying elements that increase hardness while maintaining workable malleability.

Future Innovations: Improving Tin’s Material Performance

Future innovations in tin metallurgy aim to balance malleability and hardness by developing advanced alloying techniques and nanostructured composites. Research focuses on enhancing tin's mechanical properties through grain refinement and controlled phase transformations to improve durability without sacrificing ductility. These advancements promise to expand tin's applications in flexible electronics and high-strength coatings.

Malleability vs Hardness Infographic

materialdif.com

materialdif.com