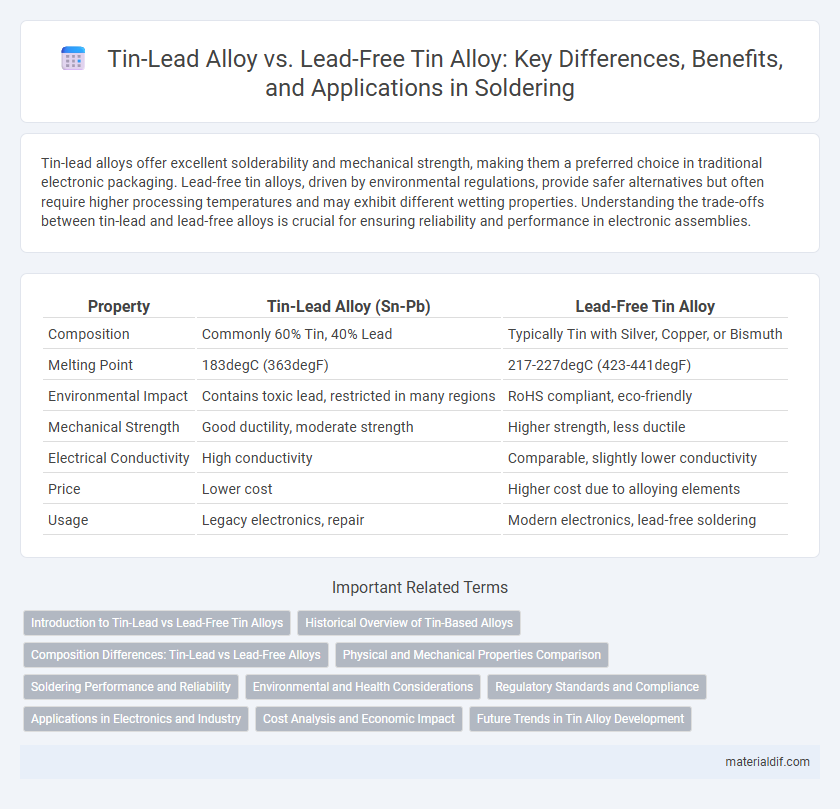

Tin-lead alloys offer excellent solderability and mechanical strength, making them a preferred choice in traditional electronic packaging. Lead-free tin alloys, driven by environmental regulations, provide safer alternatives but often require higher processing temperatures and may exhibit different wetting properties. Understanding the trade-offs between tin-lead and lead-free alloys is crucial for ensuring reliability and performance in electronic assemblies.

Table of Comparison

| Property | Tin-Lead Alloy (Sn-Pb) | Lead-Free Tin Alloy |

|---|---|---|

| Composition | Commonly 60% Tin, 40% Lead | Typically Tin with Silver, Copper, or Bismuth |

| Melting Point | 183degC (363degF) | 217-227degC (423-441degF) |

| Environmental Impact | Contains toxic lead, restricted in many regions | RoHS compliant, eco-friendly |

| Mechanical Strength | Good ductility, moderate strength | Higher strength, less ductile |

| Electrical Conductivity | High conductivity | Comparable, slightly lower conductivity |

| Price | Lower cost | Higher cost due to alloying elements |

| Usage | Legacy electronics, repair | Modern electronics, lead-free soldering |

Introduction to Tin-Lead vs Lead-Free Tin Alloys

Tin-lead alloys, traditionally used in soldering, offer excellent wetting properties and low melting points, making them ideal for reliable electrical connections. Lead-free tin alloys, developed to meet environmental regulations like RoHS, primarily use metals such as silver, copper, and bismuth to maintain mechanical strength and thermal resistance. The transition to lead-free alternatives addresses health and environmental concerns while requiring adjustments in manufacturing processes due to differences in melting behavior and mechanical properties.

Historical Overview of Tin-Based Alloys

Tin-lead alloys have historically dominated soldering applications due to their excellent wetting properties and relatively low melting points, with widespread use dating back to the early 20th century. The shift towards lead-free tin-based alloys gained momentum in the early 2000s driven by environmental regulations like the Restriction of Hazardous Substances (RoHS) directive, which restricts lead use in electronic products. Modern lead-free alloys typically combine tin with elements such as silver, copper, or bismuth to maintain performance while reducing health and environmental risks associated with lead.

Composition Differences: Tin-Lead vs Lead-Free Alloys

Tin-lead alloys typically consist of about 60-63% tin and 37-40% lead, providing a low melting point and excellent solderability ideal for electronics. Lead-free tin alloys commonly replace lead with metals such as silver, copper, and bismuth, creating compositions like SAC305 (96.5% tin, 3% silver, 0.5% copper) to meet environmental regulations without sacrificing mechanical strength or conductivity. These composition differences significantly impact melting temperature, environmental compliance, and mechanical properties in various soldering applications.

Physical and Mechanical Properties Comparison

Tin-lead alloys exhibit lower melting points around 183degC, enhancing solder fluidity, while lead-free tin alloys typically melt above 217degC, impacting processing temperatures. Lead-containing alloys offer superior ductility and fatigue resistance, whereas lead-free alternatives like tin-silver-copper provide higher tensile strength but reduced elongation. The mechanical hardness of lead-free tin alloys generally exceeds that of tin-lead, influencing joint reliability under thermal cycling and mechanical stress.

Soldering Performance and Reliability

Tin-lead alloys exhibit superior soldering performance due to their lower melting point and excellent wettability, facilitating smoother solder joints compared to lead-free tin alloys. Lead-free tin alloys, primarily composed of tin with additives like silver and copper, require higher soldering temperatures that can increase thermal stress and reduce joint reliability in sensitive electronic components. Long-term reliability of tin-lead solder joints is often favored in critical applications as they demonstrate better fatigue resistance and reduced susceptibility to tin whisker formation relative to many lead-free alternatives.

Environmental and Health Considerations

Tin-lead alloys, commonly used in electronics soldering, pose significant environmental and health risks due to lead's toxicity and potential for soil and water contamination. Lead-free tin alloys, often composed of tin with silver, copper, or bismuth, offer safer alternatives by reducing hazardous lead exposure and improving recyclability. Regulatory directives like RoHS (Restriction of Hazardous Substances) promote lead-free materials to minimize ecological damage and protect human health.

Regulatory Standards and Compliance

Tin-lead alloys have historically dominated electronics soldering but face increasing restrictions due to RoHS (Restriction of Hazardous Substances) regulations limiting lead content to 0.1%. Lead-free tin alloys, such as tin-silver-copper (SAC) compositions, comply fully with these regulations, promoting environmental safety and reducing toxic waste. Regulatory standards from organizations like the European Union and IEC demand rigorous testing and certification to ensure electronic components meet lead-free compliance for global market acceptance.

Applications in Electronics and Industry

Tin-lead alloys, known for their excellent solderability and low melting points, are widely used in traditional electronic soldering applications, ensuring strong mechanical bonds and reliable electrical connections. Lead-free tin alloys, typically composed of tin combined with silver, copper, or bismuth, have gained prominence due to environmental regulations like RoHS, favoring sustainable and non-toxic solutions in electronics manufacturing. Industrial applications of lead-free tin alloys extend to automotive and aerospace sectors, where enhanced thermal fatigue resistance and mechanical strength meet the demands of modern high-performance devices.

Cost Analysis and Economic Impact

Tin-lead alloys generally offer lower initial costs due to easier processing and established supply chains, making them economically attractive for traditional soldering applications. Lead-free tin alloys incur higher production expenses driven by more complex manufacturing processes and the need for specialized equipment, which can increase overall product costs. However, the economic impact of lead-free variants includes reduced regulatory risks and health-related liabilities, potentially lowering long-term compliance and remediation expenses.

Future Trends in Tin Alloy Development

Future trends in tin alloy development emphasize the shift from traditional tin-lead alloys to lead-free alternatives due to environmental and health regulations like RoHS and REACH. Innovations in lead-free tin alloys, such as tin-silver-copper (SAC) and tin-bismuth blends, enhance solder joint reliability, thermal fatigue resistance, and melting point optimization for electronic and automotive applications. Research continues to improve alloy performance and sustainability by reducing toxic components while maintaining or exceeding the mechanical and electrical properties of tin-lead alloys.

Tin-lead alloy vs Lead-free tin alloy Infographic

materialdif.com

materialdif.com