Tin sputtering offers precise control over film thickness and composition, providing a uniform and highly adherent coating ideal for advanced electronic applications. Tin electroplating, on the other hand, is a cost-effective method that deposits a thicker, more ductile layer suitable for corrosion resistance and solderability in mass production. Choosing between tin sputtering and electroplating depends on the specific requirements for coating uniformity, mechanical properties, and production scale in tin pet manufacturing.

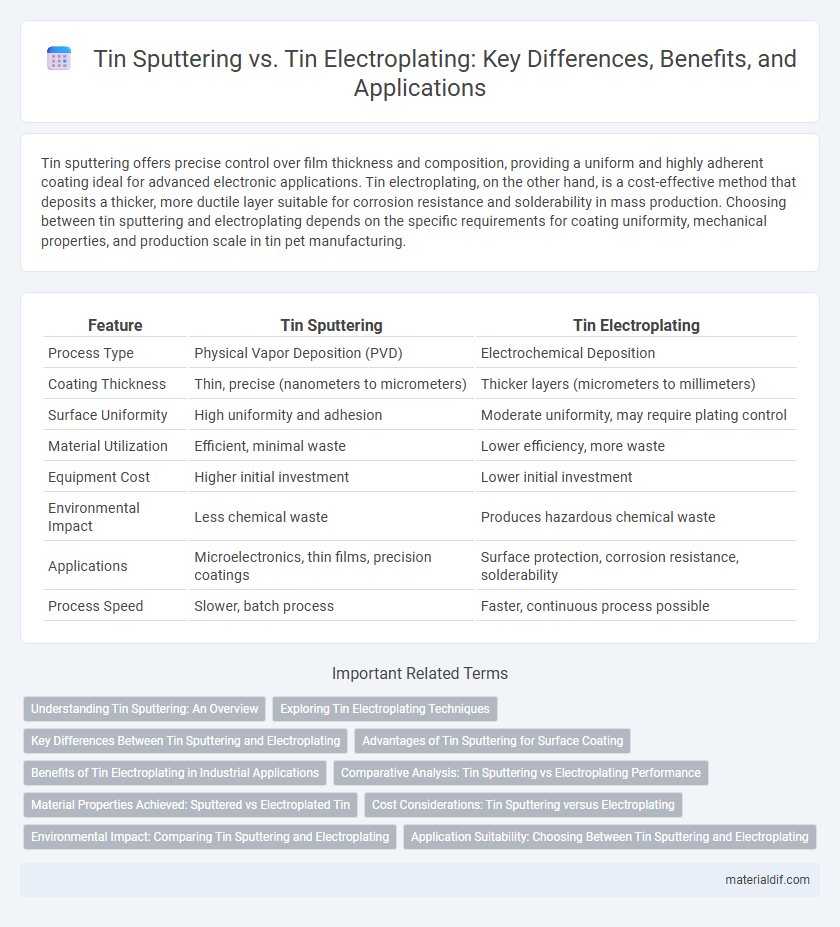

Table of Comparison

| Feature | Tin Sputtering | Tin Electroplating |

|---|---|---|

| Process Type | Physical Vapor Deposition (PVD) | Electrochemical Deposition |

| Coating Thickness | Thin, precise (nanometers to micrometers) | Thicker layers (micrometers to millimeters) |

| Surface Uniformity | High uniformity and adhesion | Moderate uniformity, may require plating control |

| Material Utilization | Efficient, minimal waste | Lower efficiency, more waste |

| Equipment Cost | Higher initial investment | Lower initial investment |

| Environmental Impact | Less chemical waste | Produces hazardous chemical waste |

| Applications | Microelectronics, thin films, precision coatings | Surface protection, corrosion resistance, solderability |

| Process Speed | Slower, batch process | Faster, continuous process possible |

Understanding Tin Sputtering: An Overview

Tin sputtering involves the physical vapor deposition process where tin atoms are ejected from a target and deposited onto a substrate, forming a thin, uniform coating. Unlike tin electroplating, which relies on electric current to reduce tin ions from a solution onto a surface, sputtering offers superior control over film thickness and composition, enhancing adhesion and corrosion resistance. This technique is widely used in semiconductor manufacturing and electronic component fabrication due to its precision and ability to create ultra-thin, high-purity tin layers.

Exploring Tin Electroplating Techniques

Tin electroplating techniques offer precise control over coating thickness and superior corrosion resistance compared to tin sputtering, which involves physical vapor deposition and tends to produce thinner, less uniform films. Electroplating utilizes an electrolytic bath to deposit tin ions onto substrates, enabling customizable layer properties and enhanced adhesion on complex geometries. This method is especially favored in electronics for ensuring excellent solderability and reliable protection against oxidation.

Key Differences Between Tin Sputtering and Electroplating

Tin sputtering produces a thin, uniform coating by bombarding a tin target with ions in a vacuum, enabling precise control over film thickness and composition ideal for microelectronic applications. Tin electroplating involves an electrochemical process where tin ions are reduced and deposited onto a substrate, resulting in a thicker, more ductile layer commonly used for corrosion resistance and solderability in printed circuit boards. Key differences include sputtering's dry, low-temperature process with superior adhesion and purity versus electroplating's wet, higher-temperature method offering greater thickness and cost-effectiveness for large-scale manufacturing.

Advantages of Tin Sputtering for Surface Coating

Tin sputtering offers superior adhesion and uniform thin-film deposition compared to tin electroplating, resulting in enhanced corrosion resistance and improved electrical conductivity for microelectronics. The vacuum-based sputtering process produces highly pure, contaminant-free coatings with precise thickness control, promoting better performance in high-reliability applications. Additionally, tin sputtering eliminates the use of harmful chemicals, making it a more environmentally friendly surface coating method.

Benefits of Tin Electroplating in Industrial Applications

Tin electroplating offers superior corrosion resistance and excellent solderability, making it a preferred choice in the electronics and automotive industries. Its uniform thin coating enhances electrical conductivity and provides a durable, non-toxic surface finish that complies with environmental regulations. Tin electroplating ensures improved adhesion and wear resistance compared to sputtering, leading to longer-lasting and more reliable industrial components.

Comparative Analysis: Tin Sputtering vs Electroplating Performance

Tin sputtering offers superior film uniformity and adhesion on complex geometries compared to tin electroplating, which often struggles with uneven deposition in intricate areas. Electroplated tin layers exhibit better corrosion resistance and higher electrical conductivity due to their thicker and denser coatings, making them ideal for applications requiring robust protection. Sputtering provides finer control over thickness at the nanoscale, enhancing surface smoothness and reducing defects, whereas electroplating is more cost-effective for large-scale, thicker coatings.

Material Properties Achieved: Sputtered vs Electroplated Tin

Sputtered tin coatings exhibit superior uniformity, higher density, and enhanced adhesion compared to electroplated tin, resulting in improved corrosion resistance and electrical conductivity. Electroplated tin often presents a thicker, more ductile layer suited for applications requiring deformation tolerance but may suffer from porosity and less consistent microstructure. Material properties achieved through sputtering include fine grain size and low surface roughness, whereas electroplating tends to produce coarser grains and higher surface irregularities.

Cost Considerations: Tin Sputtering versus Electroplating

Tin sputtering typically involves higher initial equipment costs and energy consumption compared to tin electroplating, which uses wet chemical processes with lower upfront investment. Electroplating offers cost efficiency for large-scale production due to faster deposition rates and simpler setup, while sputtering allows precise thin film control ideal for specialized high-tech applications despite higher operational expenses. Material usage in electroplating tends to be more wasteful and environmentally sensitive, potentially increasing long-term costs, whereas sputtering provides better material utilization and cleaner processing.

Environmental Impact: Comparing Tin Sputtering and Electroplating

Tin sputtering offers a lower environmental impact due to its dry process, which minimizes hazardous chemical waste and reduces water consumption compared to tin electroplating. Electroplating generates significant liquid waste containing heavy metals and acids, requiring extensive treatment before disposal. Sputtering also reduces air emissions and energy usage, making it a more eco-friendly choice for tin coating applications.

Application Suitability: Choosing Between Tin Sputtering and Electroplating

Tin sputtering offers precise, thin, and uniform coatings ideal for semiconductor devices and microelectronics requiring high purity and minimal substrate damage. Tin electroplating provides thicker, more durable layers suited for corrosion resistance and wear protection in automotive and electrical connectors. Selecting between tin sputtering and electroplating depends on application requirements for coating thickness, adhesion, and environmental durability.

Tin sputtering vs Tin electroplating Infographic

materialdif.com

materialdif.com