Single reduced tin pet containers feature a thinner metal layer on one side, providing sufficient durability while reducing material usage and weight. Double reduced tin pet containers have the metal layer minimized on both sides, offering greater weight savings and cost efficiency but requiring careful handling to maintain structural integrity. Choosing between single and double reduced depends on balancing durability needs with cost and environmental considerations.

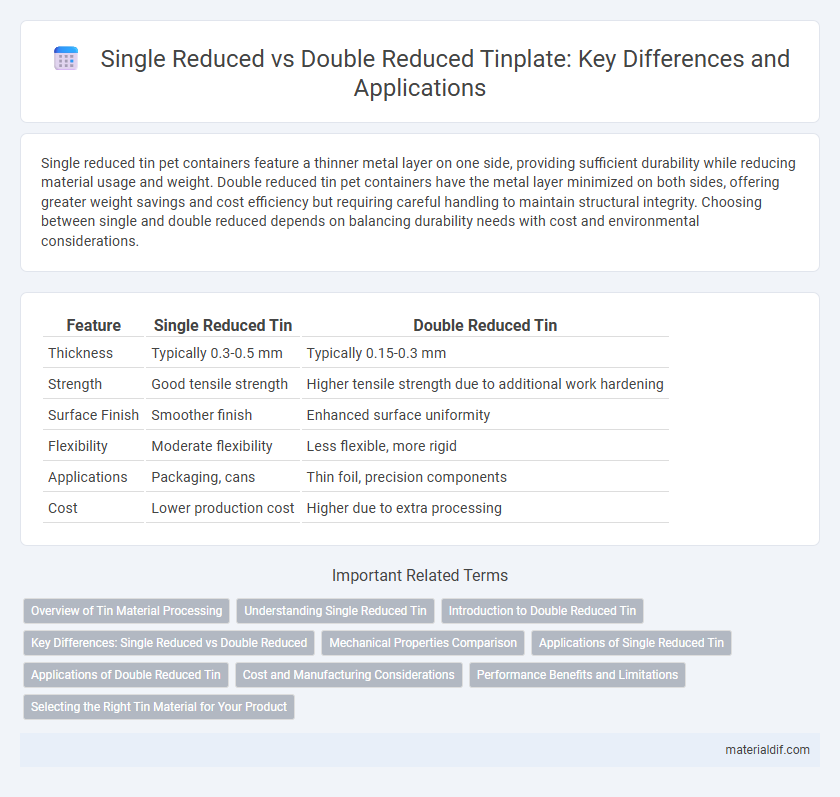

Table of Comparison

| Feature | Single Reduced Tin | Double Reduced Tin |

|---|---|---|

| Thickness | Typically 0.3-0.5 mm | Typically 0.15-0.3 mm |

| Strength | Good tensile strength | Higher tensile strength due to additional work hardening |

| Surface Finish | Smoother finish | Enhanced surface uniformity |

| Flexibility | Moderate flexibility | Less flexible, more rigid |

| Applications | Packaging, cans | Thin foil, precision components |

| Cost | Lower production cost | Higher due to extra processing |

Overview of Tin Material Processing

Single reduced tin undergoes one stage of cold rolling, reducing its thickness by approximately 50% to enhance strength and surface finish. Double reduced tin passes through two sequential rolling stages, resulting in finer grain structure, improved ductility, and superior mechanical properties. The double reduction process is preferred in applications demanding higher formability and corrosion resistance, such as in food packaging and electronics.

Understanding Single Reduced Tin

Single reduced tin refers to tin metal that has undergone one stage of reducing its oxide content, typically resulting in a product with moderate purity suitable for various industrial applications. This process removes a significant portion of impurities but retains some oxide residues, making it less refined compared to double reduced tin, which undergoes an extra refining step to achieve higher purity levels. Understanding single reduced tin is crucial for industries balancing cost and quality, as it provides sufficient purity for soldering and plating while maintaining economic efficiency.

Introduction to Double Reduced Tin

Double reduced tin features a thinner gauge and increased malleability compared to single reduced tin, making it ideal for intricate packaging applications requiring enhanced formability. Its manufacturing process involves passing the tin through two consecutive rollers, resulting in superior surface smoothness and improved mechanical properties. This advanced reduction technique optimizes tin's strength-to-thickness ratio, offering better durability without compromising lightweight characteristics.

Key Differences: Single Reduced vs Double Reduced

Single Reduced tin refers to tin that has undergone one stage of reduction, resulting in a purer form compared to its raw state but less refined than Double Reduced tin. Double Reduced tin undergoes two stages of reduction, producing a product with higher purity, improved malleability, and enhanced corrosion resistance. The key difference lies in the degree of purification, where Double Reduced tin offers superior quality and is preferred for applications requiring stringent material properties.

Mechanical Properties Comparison

Single reduced tin exhibits higher tensile strength and improved hardness compared to double reduced tin, making it more suitable for applications requiring enhanced mechanical durability. Double reduced tin demonstrates greater ductility and elongation, allowing for better formability and resistance to cracking under deformation. The trade-off between strength and flexibility in these reduction processes is critical for tailoring tin's mechanical properties to specific industrial needs.

Applications of Single Reduced Tin

Single reduced tin, also known as 99.9% pure tin, is widely used in soldering applications for electronics due to its excellent wetting properties and low melting point. It serves as a crucial component in protective coatings for steel and other metals, enhancing corrosion resistance in food packaging and automotive parts. The versatility of single reduced tin extends to chemical industries, where it acts as a catalyst and reducing agent in various processes.

Applications of Double Reduced Tin

Double reduced tin exhibits superior malleability and ductility compared to single reduced tin, making it ideal for applications requiring extensive forming and shaping. It is commonly used in the manufacturing of intricate electronic components, high-quality solder, and specialized packaging materials that demand enhanced mechanical properties. The improved grain structure of double reduced tin also contributes to increased corrosion resistance, extending its usability in harsher environments.

Cost and Manufacturing Considerations

Single reduced tin sheets offer a cost-effective solution due to fewer processing steps compared to double reduced sheets, resulting in lower manufacturing expenses. Double reduced tin provides enhanced mechanical properties and surface finish, which may justify higher costs in applications requiring superior quality. Manufacturers must balance production efficiency and material performance when selecting between single and double reduced tin based on project specifications and budget constraints.

Performance Benefits and Limitations

Single reduced tin offers precise thickness control with enhanced surface finish, ensuring reliable solderability and excellent electrical conductivity for electronic applications. Double reduced tin, processed through additional cold rolling, achieves superior flatness and dimensional stability, improving mechanical strength but may introduce higher internal stresses that can affect long-term durability. Performance benefits of single reduced tin include better ductility and ease of forming, while double reduced tin excels in structural rigidity and wear resistance, with limitations in flexibility and potential for increased brittleness.

Selecting the Right Tin Material for Your Product

Single reduced tin offers moderate thickness and higher ductility, ideal for applications requiring easy forming and moderate corrosion resistance. Double reduced tin provides a thinner gauge with increased strength and improved surface smoothness, suitable for precision components and enhanced protective coatings. Choosing between single and double reduced tin depends on balancing flexibility and durability to match the specific requirements of your product's manufacturing process and end-use environment.

Single Reduced vs Double Reduced Infographic

materialdif.com

materialdif.com