Pure tin offers excellent corrosion resistance and flexibility, making it ideal for applications requiring non-toxic coatings and low-temperature soldering. Tin alloys, containing elements like silver or copper, provide enhanced strength, hardness, and thermal stability, which improve durability and performance in demanding environments. Choosing between pure tin and tin alloy depends on the specific requirements for mechanical properties and environmental resistance.

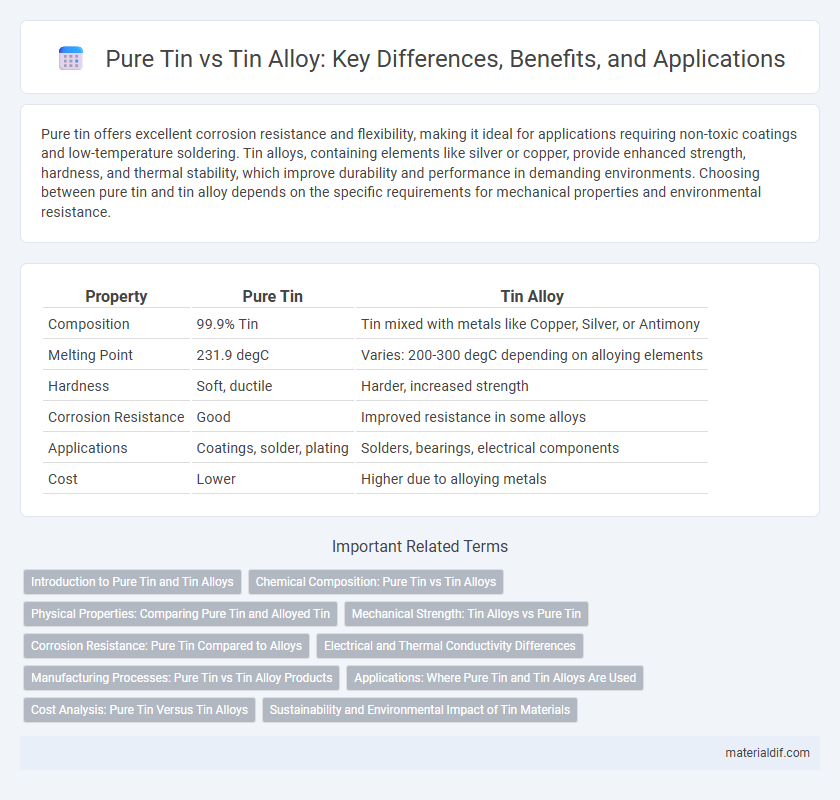

Table of Comparison

| Property | Pure Tin | Tin Alloy |

|---|---|---|

| Composition | 99.9% Tin | Tin mixed with metals like Copper, Silver, or Antimony |

| Melting Point | 231.9 degC | Varies: 200-300 degC depending on alloying elements |

| Hardness | Soft, ductile | Harder, increased strength |

| Corrosion Resistance | Good | Improved resistance in some alloys |

| Applications | Coatings, solder, plating | Solders, bearings, electrical components |

| Cost | Lower | Higher due to alloying metals |

Introduction to Pure Tin and Tin Alloys

Pure tin, a soft, malleable metal with a melting point of 231.9degC, is primarily used for coating and soldering due to its excellent corrosion resistance and non-toxic nature. Tin alloys, such as bronze (tin and copper) and pewter (tin, antimony, copper), offer enhanced mechanical strength, durability, and improved wear resistance compared to pure tin. These alloys expand tin's applications in industries like electronics, automotive, and construction, where higher performance materials are essential.

Chemical Composition: Pure Tin vs Tin Alloys

Pure tin, consisting of nearly 99.9% tin (Sn), offers excellent corrosion resistance and electrical conductivity but lacks mechanical strength. Tin alloys, such as tin-lead (Sn-Pb), tin-silver-copper (SAC), and tin-copper (Sn-Cu), incorporate additional elements to enhance hardness, solderability, and thermal resistance. The chemical composition of these alloys varies, with lead content commonly ranging from 1% to 60% in Sn-Pb solders, while SAC alloys typically contain around 96% tin, 3% silver, and 0.5% copper to balance performance and environmental safety.

Physical Properties: Comparing Pure Tin and Alloyed Tin

Pure tin exhibits a low melting point of 231.9degC and a density of 7.31 g/cm3, making it soft and malleable with excellent corrosion resistance. Alloyed tin, often combined with metals like copper, silver, or lead, demonstrates enhanced mechanical strength, higher hardness, and improved wear resistance while sometimes displaying slightly higher melting points and altered densities depending on the specific alloy composition. These physical property variations make alloyed tin more suitable for structural applications requiring durability, whereas pure tin remains ideal for coatings and soldering due to its ductility and solderability.

Mechanical Strength: Tin Alloys vs Pure Tin

Tin alloys exhibit significantly higher mechanical strength compared to pure tin, making them more suitable for structural applications. Pure tin has a low tensile strength and is prone to deformation under stress, whereas alloying elements such as copper, silver, and bismuth enhance hardness and tensile properties. This improvement in mechanical strength allows tin alloys to withstand greater loads and resist wear better than pure tin.

Corrosion Resistance: Pure Tin Compared to Alloys

Pure tin offers superior corrosion resistance due to its stable oxide layer that protects surfaces from environmental factors, making it ideal for applications requiring longevity in humid or acidic conditions. Tin alloys, while often enhanced for mechanical strength or conductivity, may exhibit reduced corrosion resistance depending on the alloying elements, such as copper or antimony, which can compromise the protective oxide layer. Selecting pure tin over tin alloys ensures better performance in environments where exposure to moisture and chemical agents is prevalent.

Electrical and Thermal Conductivity Differences

Pure tin exhibits higher electrical conductivity compared to tin alloys due to the absence of alloying elements that disrupt electron flow. Thermal conductivity in pure tin is also superior, allowing more efficient heat transfer, which is critical in electronic applications. Tin alloys, while offering improved mechanical strength, show reduced electrical and thermal conductivity as a result of increased electron scattering from alloying constituents.

Manufacturing Processes: Pure Tin vs Tin Alloy Products

Manufacturing processes for pure tin often emphasize precise melting and casting to preserve its high ductility and corrosion resistance, making it ideal for electronic solder and plating applications. Tin alloys, such as tin-copper or tin-silver, require controlled alloying and heat treatment techniques to enhance mechanical strength and wear resistance, essential in automotive and aerospace components. Advanced processes like powder metallurgy and vacuum induction melting optimize the material properties of tin alloys, ensuring improved performance in demanding industrial environments.

Applications: Where Pure Tin and Tin Alloys Are Used

Pure tin is predominantly utilized in electronics for soldering due to its excellent conductivity and corrosion resistance, making it essential in circuit board manufacturing and coating applications. Tin alloys, such as bronze and pewter, are favored in applications requiring enhanced mechanical strength and durability, including musical instruments, bearings, and roofing materials. The automotive and aerospace industries rely heavily on tin alloys for their superior wear resistance and thermal stability in engine components and protective coatings.

Cost Analysis: Pure Tin Versus Tin Alloys

Pure tin typically incurs higher costs due to its refining process and limited mechanical properties, making it less economical for large-scale industrial use. Tin alloys, such as tin-lead or tin-silver blends, offer enhanced strength and corrosion resistance at a lower material cost, improving overall cost efficiency in manufacturing. The choice between pure tin and tin alloys directly impacts production budgets, with alloys often preferred for cost-sensitive applications requiring durability.

Sustainability and Environmental Impact of Tin Materials

Pure tin offers superior recyclability and generates less environmental pollution compared to tin alloys, which often contain elements like lead or antimony that complicate recycling processes and elevate toxicity concerns. Tin alloys, while enhancing mechanical properties and corrosion resistance, typically involve more energy-intensive extraction and refining methods, increasing their carbon footprint. Sustainable use of tin materials favors pure tin to minimize ecological impact and facilitate circular economy practices within the metal industry.

pure tin vs tin alloy Infographic

materialdif.com

materialdif.com