Tin pet solder alloys Sn96.5 and Sn63 differ mainly in composition and melting points, with Sn96.5 containing 96.5% tin and 3.5% silver, offering higher thermal and mechanical strength ideal for high-reliability electronics. Sn63, composed of 63% tin and 37% lead, melts at a lower temperature of 183degC, providing excellent wetting properties and ease of reflow in traditional soldering applications. Choosing between Sn96.5 and Sn63 depends on the balance needed between lead-free requirements, thermal performance, and application-specific solderability.

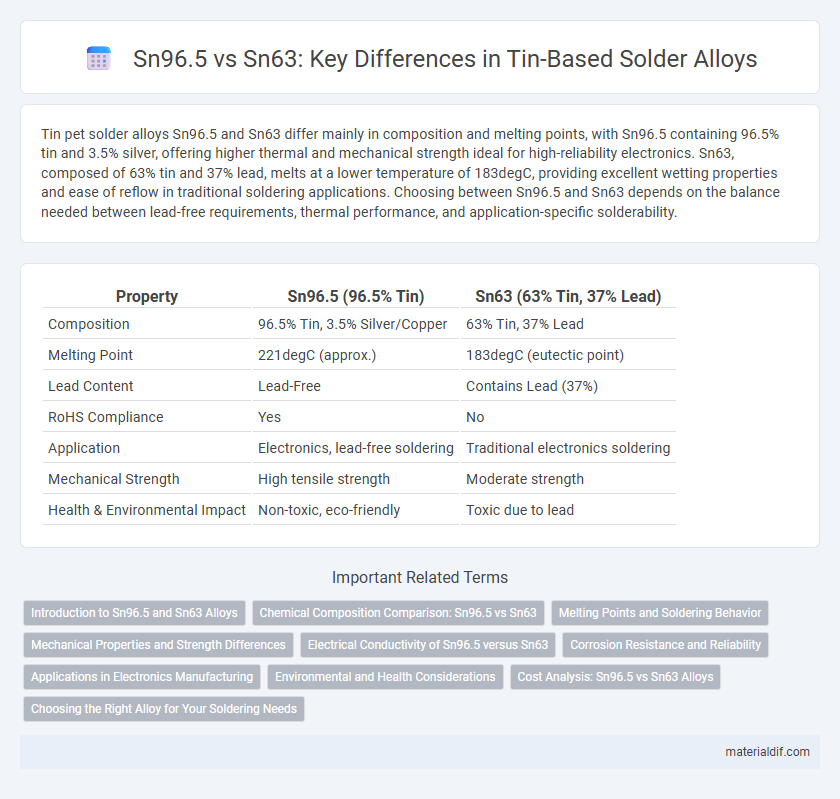

Table of Comparison

| Property | Sn96.5 (96.5% Tin) | Sn63 (63% Tin, 37% Lead) |

|---|---|---|

| Composition | 96.5% Tin, 3.5% Silver/Copper | 63% Tin, 37% Lead |

| Melting Point | 221degC (approx.) | 183degC (eutectic point) |

| Lead Content | Lead-Free | Contains Lead (37%) |

| RoHS Compliance | Yes | No |

| Application | Electronics, lead-free soldering | Traditional electronics soldering |

| Mechanical Strength | High tensile strength | Moderate strength |

| Health & Environmental Impact | Non-toxic, eco-friendly | Toxic due to lead |

Introduction to Sn96.5 and Sn63 Alloys

Sn96.5 and Sn63 are widely used tin-based solder alloys, with Sn96.5 comprising 96.5% tin and 3.5% silver, offering excellent mechanical strength and thermal fatigue resistance for electronics assembly. Sn63, an eutectic alloy consisting of 63% tin and 37% lead, is prized for its low melting point of 183degC and smooth, reliable solder joints in traditional soldering processes. Both alloys serve critical roles in electronic manufacturing, balancing factors like melting behavior, mechanical properties, and environmental compliance.

Chemical Composition Comparison: Sn96.5 vs Sn63

Sn96.5 consists of 96.5% tin and 3.5% silver, providing excellent mechanical strength and thermal fatigue resistance, making it ideal for high-stress electronic applications. Sn63 is an eutectic alloy with 63% tin and 37% lead, known for its lower melting point of 183degC, ensuring a sharp transition from liquid to solid and smoother soldering processes. The lead-free Sn96.5 is preferred for environmental compliance, while Sn63 offers superior wetting characteristics and long-standing reliability in traditional soldering.

Melting Points and Soldering Behavior

Sn96.5 solder has a melting point of approximately 227degC compared to Sn63's melting point at 183degC, indicating Sn63 melts at a significantly lower temperature. The lower melting point of Sn63 allows for faster soldering with reduced thermal stress on components, improving joint reliability in sensitive electronic assemblies. Sn96.5 offers better mechanical strength and is preferred for applications requiring higher thermal and mechanical endurance despite the higher melting point.

Mechanical Properties and Strength Differences

Sn96.5 solder alloy offers higher tensile strength compared to Sn63, making it more suitable for applications requiring enhanced mechanical durability. The increased tin content in Sn96.5 results in improved creep resistance and hardness, whereas Sn63 exhibits better electrical conductivity but lower mechanical strength. Sn63, with its eutectic composition, melts at a lower temperature and provides excellent wettability but lacks the robust mechanical properties of Sn96.5.

Electrical Conductivity of Sn96.5 versus Sn63

Sn96.5, a lead-free solder alloy with 96.5% tin, exhibits lower electrical conductivity compared to Sn63, a eutectic solder containing 63% tin and 37% lead, due to the higher tin content and absence of lead enhancing conductivity in Sn63. Electrical conductivity of Sn63 typically measures around 7.42 MS/m (mega siemens per meter), whereas Sn96.5 demonstrates values closer to 6.3 MS/m. The reduced conductivity in Sn96.5 affects signal integrity in high-frequency electronic applications, making Sn63 preferable where superior electrical performance is critical.

Corrosion Resistance and Reliability

Sn96.5 solder alloy offers superior corrosion resistance compared to Sn63, making it more reliable for applications exposed to harsh environments. The higher tin content in Sn96.5 enhances its durability against oxidation and chemical degradation, resulting in longer-lasting joints. This improved corrosion resistance translates into increased reliability in electronic assemblies where environmental factors are critical.

Applications in Electronics Manufacturing

Sn96.5 solder offers higher melting points and stronger mechanical stability, making it ideal for automotive electronics and power devices requiring durability under thermal stress. Sn63 solder, with its eutectic composition and lower melting point, excels in precision electronics like smartphones and fine-pitch circuit boards where reliable, clean joints and reduced thermal damage are critical. Both compositions significantly impact soldering quality and product reliability across diverse electronics manufacturing sectors.

Environmental and Health Considerations

Sn96.5 solder contains 96.5% tin and 3.5% silver, offering a lead-free alternative that reduces toxic lead exposure, thereby lessening environmental contamination and health risks. Sn63 solder, an alloy of 63% tin and 37% lead, poses significant health hazards due to lead's neurotoxicity and environmental persistence, necessitating safer handling and disposal practices. Transitioning to Sn96.5 supports compliance with RoHS regulations and promotes workplace safety by minimizing lead-related health issues.

Cost Analysis: Sn96.5 vs Sn63 Alloys

Sn96.5 alloy, composed of 96.5% tin and 3.5% silver or copper, typically incurs higher material costs due to its premium tin content and enhanced mechanical properties compared to Sn63, which is an eutectic alloy of 63% tin and 37% lead. Sn63 offers cost advantages with lower raw material prices and easier soldering performance, making it prevalent in traditional electronics manufacturing. The choice between Sn96.5 and Sn63 hinges on balancing the higher price of lead-free Sn96.5 against Sn63's cost-efficiency and regulatory considerations surrounding lead usage.

Choosing the Right Alloy for Your Soldering Needs

Sn96.5 offers superior mechanical strength and higher melting point compared to Sn63, making it ideal for applications requiring durability and heat resistance. Sn63, an eutectic alloy composed of 63% tin and 37% lead, provides excellent wetting properties and a lower melting temperature, resulting in smoother, faster solder joints ideal for delicate electronics. Selecting between Sn96.5 and Sn63 depends on balancing thermal requirements with the need for precision in electrical conductivity and mechanical reliability.

Sn96.5 vs Sn63 Infographic

materialdif.com

materialdif.com