Bismuth-tin solder offers lower melting points and reduced thermal stress, making it ideal for delicate electronic components, while silver-tin solder provides superior mechanical strength and corrosion resistance, suitable for demanding industrial applications. Bismuth-tin alloys also exhibit better wetting properties on low-surface-energy metals, whereas silver-tin formulations enhance conductivity and thermal performance. Choosing between these solders depends on specific requirements like temperature sensitivity, mechanical durability, and electrical conductivity in the assembly process.

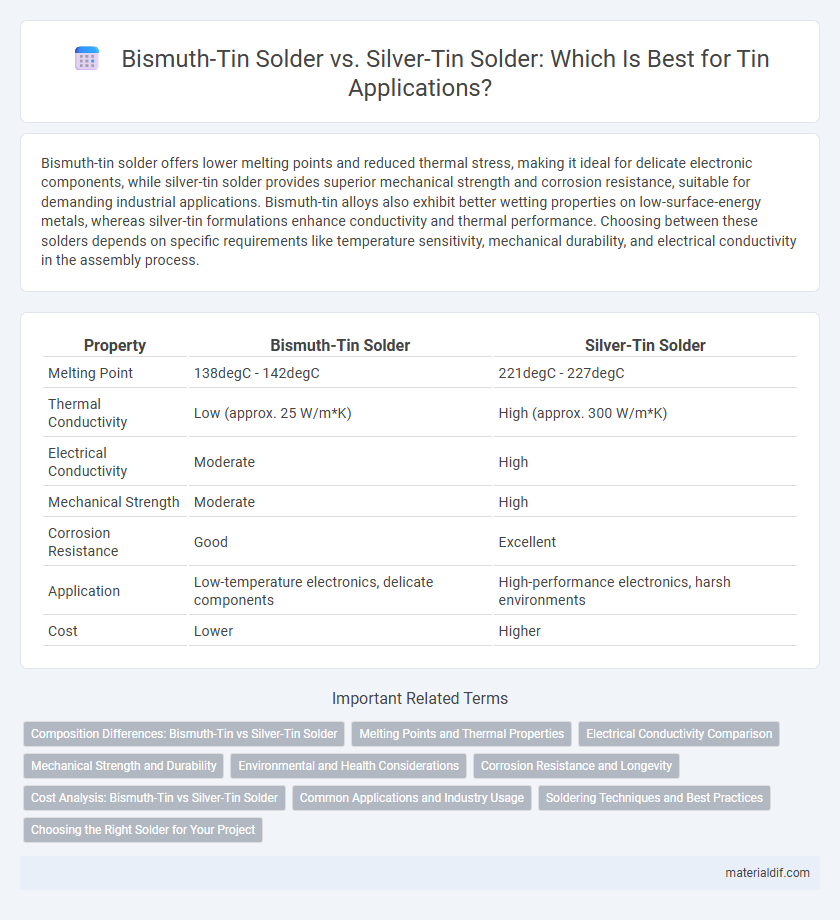

Table of Comparison

| Property | Bismuth-Tin Solder | Silver-Tin Solder |

|---|---|---|

| Melting Point | 138degC - 142degC | 221degC - 227degC |

| Thermal Conductivity | Low (approx. 25 W/m*K) | High (approx. 300 W/m*K) |

| Electrical Conductivity | Moderate | High |

| Mechanical Strength | Moderate | High |

| Corrosion Resistance | Good | Excellent |

| Application | Low-temperature electronics, delicate components | High-performance electronics, harsh environments |

| Cost | Lower | Higher |

Composition Differences: Bismuth-Tin vs Silver-Tin Solder

Bismuth-tin solder typically consists of around 58% bismuth and 42% tin, offering a low melting point near 138degC and excellent wettability for delicate electronic components. In contrast, silver-tin solder contains approximately 96% tin with 4% silver, increasing melting temperature to about 221degC and enhancing mechanical strength and thermal conductivity. These compositional differences significantly impact soldering performance, with bismuth-tin preferred for low-temperature applications and silver-tin favored in high-reliability, high-temperature environments.

Melting Points and Thermal Properties

Bismuth-tin solder typically melts around 138degC to 142degC, offering low melting points ideal for temperature-sensitive components and delicate electronic assemblies. Silver-tin solder, by contrast, melts at a significantly higher temperature near 221degC, providing superior thermal conductivity and mechanical strength for robust and high-temperature applications. The choice between these solders hinges on balancing low melting points for easy processing and thermal properties needed to ensure joint durability and heat resistance.

Electrical Conductivity Comparison

Bismuth-tin solder exhibits lower electrical conductivity compared to silver-tin solder due to the intrinsic properties of bismuth, which is a poor conductor of electricity. Silver-tin solder contains silver, a highly conductive metal, resulting in superior electrical performance ideal for sensitive electronic connections. Consequently, silver-tin solder is preferred in applications requiring optimal signal integrity and minimal electrical resistance.

Mechanical Strength and Durability

Bismuth-tin solder offers moderate mechanical strength and excellent thermal performance, making it suitable for low-stress electronic applications. Silver-tin solder exhibits superior mechanical strength and enhanced durability due to its robust intermetallic compounds, which are ideal for high-stress or industrial environments. The increased hardness and tensile strength of silver-tin solder contribute to better resistance against mechanical fatigue and thermal cycling compared to bismuth-tin alloys.

Environmental and Health Considerations

Bismuth-tin solder offers a lead-free alternative with lower toxicity and reduced environmental impact compared to traditional lead-based solders, making it safer for both human health and ecosystems. Silver-tin solder contains silver, which is more costly and may pose minimal toxicity concerns, but still generally presents fewer health risks than lead-containing solders. Both materials support compliance with RoHS regulations, promoting environmentally responsible electronics manufacturing.

Corrosion Resistance and Longevity

Bismuth-tin solder offers enhanced corrosion resistance compared to silver-tin solder, making it ideal for electronic applications requiring long-term reliability. The reduced galvanic corrosion in bismuth-tin alloys extends solder joint longevity, particularly in humid or chemically aggressive environments. Silver-tin solder, while mechanically robust, may experience faster degradation due to higher susceptibility to corrosion in such conditions.

Cost Analysis: Bismuth-Tin vs Silver-Tin Solder

Bismuth-tin solder generally offers lower material costs compared to silver-tin solder due to the lower price of bismuth relative to silver. The manufacturing process for bismuth-tin solder is often less energy-intensive, contributing to overall cost savings in production. However, silver-tin solder provides superior mechanical strength and thermal conductivity, which may justify its higher cost in specialized applications.

Common Applications and Industry Usage

Bismuth-Tin solder is commonly used in electronics manufacturing for its low melting point and excellent wettability, making it ideal for delicate components and temperature-sensitive assemblies. Silver-Tin solder is favored in aerospace and automotive industries due to its high mechanical strength and superior thermal and electrical conductivity. Both solders serve critical roles in precision soldering applications, with Bismuth-Tin preferred for eco-friendly, low-temperature processes and Silver-Tin chosen for high-reliability, high-stress environments.

Soldering Techniques and Best Practices

Bismuth-tin solder offers a lower melting point around 138degC, enabling precise temperature control crucial for delicate electronic components, while silver-tin solder melts at approximately 221degC, providing stronger mechanical bonds suitable for high-stress applications. Effective soldering techniques for bismuth-tin include carefully calibrated heat profiles to avoid thermal shock, whereas silver-tin soldering requires robust fluxes to ensure proper wetting and minimize oxidation. Best practices involve selecting solder alloys based on component sensitivity and mechanical requirements, optimizing flux type and quantity, and employing controlled heating to achieve clean, reliable joints with minimal voids and defects.

Choosing the Right Solder for Your Project

Bismuth-tin solder offers a lower melting point around 138degC, making it ideal for temperature-sensitive electronics, while silver-tin solder provides superior mechanical strength and electrical conductivity with melting points near 217degC to 221degC. Choosing the right solder depends on the specific project requirements such as thermal exposure, joint durability, and conductivity needs. Projects demanding precision and minimal thermal stress benefit from bismuth-tin, whereas those requiring robust, high-performance joints favor silver-tin solder.

Bismuth-Tin Solder vs Silver-Tin Solder Infographic

materialdif.com

materialdif.com