Loose coat tinplate features a thicker and more uneven tin layer, offering superior corrosion resistance and better solderability compared to tight coat tinplate. Tight coat tinplate, with a thinner and smoother tin layer, provides a more uniform surface ideal for high-speed manufacturing processes but may have slightly reduced protection against moisture and chemicals. Choosing between loose and tight coat tinplate depends on the specific application requirements for durability and production efficiency in tin pet packaging.

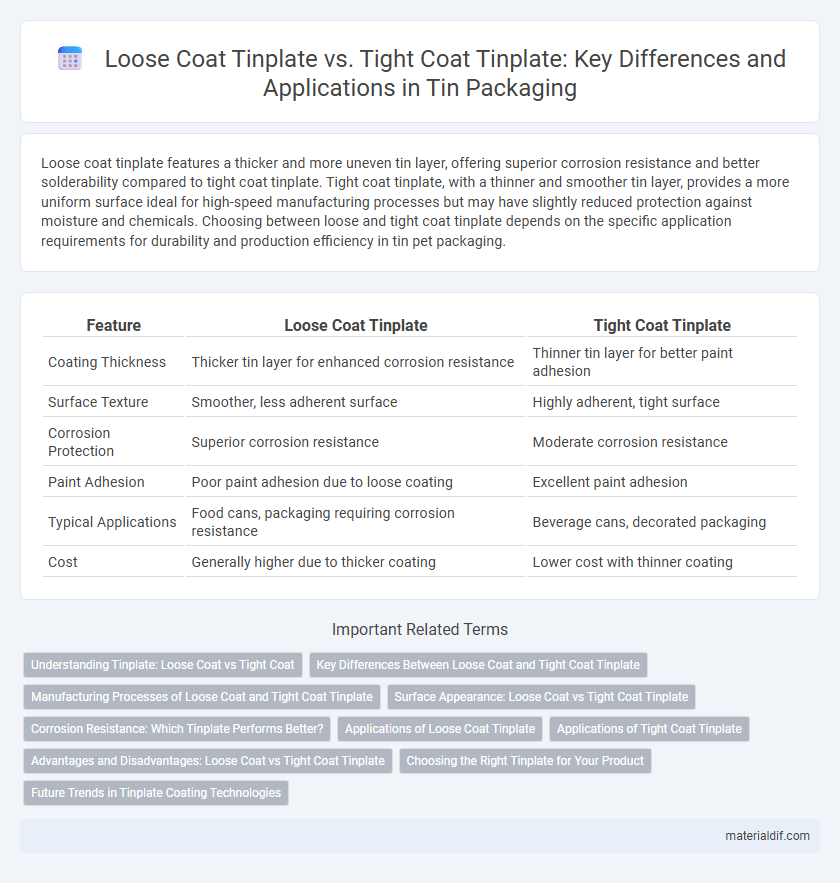

Table of Comparison

| Feature | Loose Coat Tinplate | Tight Coat Tinplate |

|---|---|---|

| Coating Thickness | Thicker tin layer for enhanced corrosion resistance | Thinner tin layer for better paint adhesion |

| Surface Texture | Smoother, less adherent surface | Highly adherent, tight surface |

| Corrosion Protection | Superior corrosion resistance | Moderate corrosion resistance |

| Paint Adhesion | Poor paint adhesion due to loose coating | Excellent paint adhesion |

| Typical Applications | Food cans, packaging requiring corrosion resistance | Beverage cans, decorated packaging |

| Cost | Generally higher due to thicker coating | Lower cost with thinner coating |

Understanding Tinplate: Loose Coat vs Tight Coat

Loose coat tinplate features a thinner, less uniformly applied tin layer, resulting in a matte finish with reduced corrosion resistance compared to tight coat tinplate. Tight coat tinplate has a thicker, more evenly distributed tin coating that provides superior protection against rust and enhances solderability in packaging and food cans. The choice between loose coat and tight coat tinplate impacts durability, shelf life, and suitability for different manufacturing processes.

Key Differences Between Loose Coat and Tight Coat Tinplate

Loose coat tinplate features a thicker, uneven tin layer that enhances solderability and corrosion resistance but may lead to reduced surface smoothness. Tight coat tinplate has a thinner, more uniform tin coating providing superior surface finish and printability, ideal for applications requiring precise aesthetics. The key differences lie in coating thickness, surface texture, and suitability for specific manufacturing processes such as soldering or printing.

Manufacturing Processes of Loose Coat and Tight Coat Tinplate

Loose coat tinplate is produced by applying a thicker layer of molten tin onto the steel substrate, allowing the tin to solidify with a rough, porous surface that enhances paint adherence and resistance to corrosion. Tight coat tinplate undergoes a thinner, more controlled tin coating process combined with a final cold rolling step, creating a smooth, dense layer that improves surface finish and mechanical properties. Manufacturing loose coat involves higher tin content and less post-treatment, while tight coat requires precise temperature control and cold rolling for refined surface structure.

Surface Appearance: Loose Coat vs Tight Coat Tinplate

Loose coat tinplate has a matte or dull surface appearance due to a thicker layer of loosely adherent tin, which can result in a grainy or uneven texture. Tight coat tinplate features a smooth, shiny, and bright surface because the tin layer is tightly bonded to the steel substrate, minimizing surface imperfections and providing superior corrosion resistance. The surface finish quality of tight coat tinplate makes it preferable for applications requiring aesthetic appeal and enhanced protection.

Corrosion Resistance: Which Tinplate Performs Better?

Loose coat tinplate typically offers better corrosion resistance due to its thicker and more porous tin layer, which provides enhanced protection against environmental factors and moisture penetration. Tight coat tinplate has a thinner, more uniform tin layer that prioritizes surface smoothness and printability but may be less effective in resisting corrosion over time. Choosing loose coat tinplate is ideal for applications requiring superior durability and longer-lasting corrosion protection.

Applications of Loose Coat Tinplate

Loose Coat Tinplate is primarily used in food and beverage packaging where enhanced corrosion resistance and printability are essential. Its thicker and less tightly bonded tin layer provides superior protection against acidic and oily food contents. Common applications include canned fruits, vegetables, and beverages requiring extended shelf life and high-quality visual appeal.

Applications of Tight Coat Tinplate

Tight coat tinplate offers superior corrosion resistance and a smoother surface finish, making it ideal for packaging applications such as food cans, beverage containers, and aerosol cans where product preservation and hygiene are critical. This type of tinplate is widely used in the food and beverage industry due to its enhanced ability to withstand exposure to acidic contents and high temperatures during processing. Its durable and uniform coating also makes it suitable for manufacturing components requiring long-term durability and aesthetic appeal.

Advantages and Disadvantages: Loose Coat vs Tight Coat Tinplate

Loose coat tinplate offers better weldability and is easier to form, reducing manufacturing defects in packaging applications, but it is more susceptible to corrosion and has lower surface smoothness compared to tight coat tinplate. Tight coat tinplate provides superior corrosion resistance and a smoother surface finish, enhancing product shelf life and aesthetic appeal, although it presents challenges in weldability and can increase production costs. Selecting between loose and tight coat tinplate depends on prioritizing corrosion resistance and appearance versus ease of fabrication and cost-effectiveness.

Choosing the Right Tinplate for Your Product

Loose coat tinplate provides a thicker, less adherent tin layer that enhances solderability and corrosion resistance, making it ideal for packaging requiring easy opening and strong protection. Tight coat tinplate features a thinner, highly bonded tin layer that offers superior surface smoothness and printability, suitable for high-quality decorative packaging and food containers. Selecting the right tinplate depends on balancing factors like product shelf life, manufacturing process, and end-use requirements.

Future Trends in Tinplate Coating Technologies

Future trends in tinplate coating technologies emphasize the development of advanced loose coat and tight coat tinplates with enhanced corrosion resistance and improved adhesion properties. Innovations include nanocoatings and environmentally friendly hybrid coatings designed to extend shelf life and reduce environmental impact. Research focuses on optimizing coating thickness and uniformity to meet the growing demand for sustainable packaging and high-performance food-grade containers.

Loose Coat Tinplate vs Tight Coat Tinplate Infographic

materialdif.com

materialdif.com