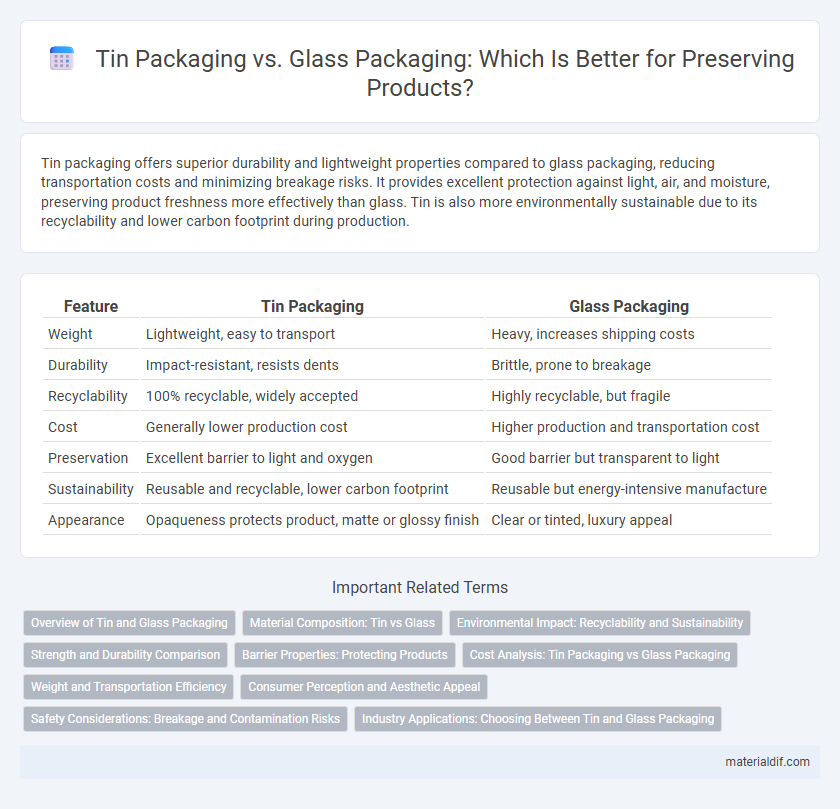

Tin packaging offers superior durability and lightweight properties compared to glass packaging, reducing transportation costs and minimizing breakage risks. It provides excellent protection against light, air, and moisture, preserving product freshness more effectively than glass. Tin is also more environmentally sustainable due to its recyclability and lower carbon footprint during production.

Table of Comparison

| Feature | Tin Packaging | Glass Packaging |

|---|---|---|

| Weight | Lightweight, easy to transport | Heavy, increases shipping costs |

| Durability | Impact-resistant, resists dents | Brittle, prone to breakage |

| Recyclability | 100% recyclable, widely accepted | Highly recyclable, but fragile |

| Cost | Generally lower production cost | Higher production and transportation cost |

| Preservation | Excellent barrier to light and oxygen | Good barrier but transparent to light |

| Sustainability | Reusable and recyclable, lower carbon footprint | Reusable but energy-intensive manufacture |

| Appearance | Opaqueness protects product, matte or glossy finish | Clear or tinted, luxury appeal |

Overview of Tin and Glass Packaging

Tin packaging offers exceptional durability, corrosion resistance, and lightweight properties, making it ideal for preserving food and beverages while ensuring long shelf life. Glass packaging provides excellent chemical stability and transparency, allowing consumers to view contents easily while maintaining product purity and flavor integrity. Both materials contribute uniquely to packaging solutions, with tin excelling in protection and recyclability, and glass valued for its inert nature and premium presentation.

Material Composition: Tin vs Glass

Tin packaging consists primarily of tin-plated steel or tinplate, which combines the strength of steel with the corrosion resistance of tin, making it ideal for preserving food and beverages. In contrast, glass packaging is made from silica sand, soda ash, and limestone, providing a chemically inert and non-porous container that prevents interaction with the contents. The material composition of tin ensures durability and lightweight properties, while glass offers superior clarity and recyclability.

Environmental Impact: Recyclability and Sustainability

Tin packaging offers higher recyclability rates due to its durability and ease of metal recovery, making it a sustainable option compared to glass. Glass packaging requires more energy-intensive recycling processes and is prone to breakage, increasing waste. Choosing tin reduces environmental impact by promoting efficient circular use and minimizing resource depletion.

Strength and Durability Comparison

Tin packaging offers superior strength and durability compared to glass packaging due to its resistance to breakage and impact, making it ideal for transportation and rough handling. Unlike glass, tin containers are less prone to shattering or cracking under pressure, reducing product loss and contamination risks. The corrosion-resistant properties of tin also enhance long-term storage, maintaining product integrity over extended periods.

Barrier Properties: Protecting Products

Tin packaging offers superior barrier properties by effectively preventing moisture, oxygen, and light infiltration, thereby extending product shelf life and preserving freshness. Unlike glass packaging, tin provides a more resilient and puncture-resistant shield against external contaminants and physical damage during transportation. These robust barrier properties make tin an ideal choice for packaging perishable goods and sensitive products.

Cost Analysis: Tin Packaging vs Glass Packaging

Tin packaging generally offers lower production and transportation costs compared to glass packaging due to its lightweight and durability, reducing shipping expenses and breakage losses. The recyclability of tin also contributes to cost efficiency by minimizing raw material expenses, whereas glass recycling processes tend to be more energy-intensive and expensive. Overall, tin packaging presents a more cost-effective solution for manufacturers aiming to optimize logistics and sustainability budgets.

Weight and Transportation Efficiency

Tin packaging weighs significantly less than glass, reducing overall shipment weight and lowering transportation costs. Its lightweight nature enhances fuel efficiency during transit, making tin an economically and environmentally advantageous choice for packaging. This efficiency supports higher shipment volumes per transport load, optimizing logistics operations.

Consumer Perception and Aesthetic Appeal

Tin packaging appeals to consumers through its durability and vintage aesthetic, often perceived as premium and environmentally friendly compared to glass. Consumers associate tin with reusability and protection against light and air, enhancing product freshness and quality perception. Glass packaging, while considered elegant and transparent for product visibility, may be seen as fragile and less convenient, impacting consumer preference in various market segments.

Safety Considerations: Breakage and Contamination Risks

Tin packaging offers superior safety by significantly reducing breakage risks compared to glass packaging, which is fragile and prone to shattering. The hermetic sealing properties of tin cans minimize contamination risks by providing an airtight barrier against external pollutants. Glass containers, while inert, can pose safety hazards if broken, leading to potential contamination and physical injury.

Industry Applications: Choosing Between Tin and Glass Packaging

Tin packaging offers superior durability and lightweight properties, making it ideal for food and beverage industries requiring extended shelf life and protection from external contaminants. Glass packaging excels in preserving flavor and is preferred in the pharmaceutical and premium beverage sectors for its inert and recyclable nature. Industry applications weigh factors such as cost-efficiency, product safety, and environmental impact when selecting between tin and glass packaging solutions.

Tin packaging vs Glass packaging Infographic

materialdif.com

materialdif.com